MAN-0012 Rev. I Page | 18

3

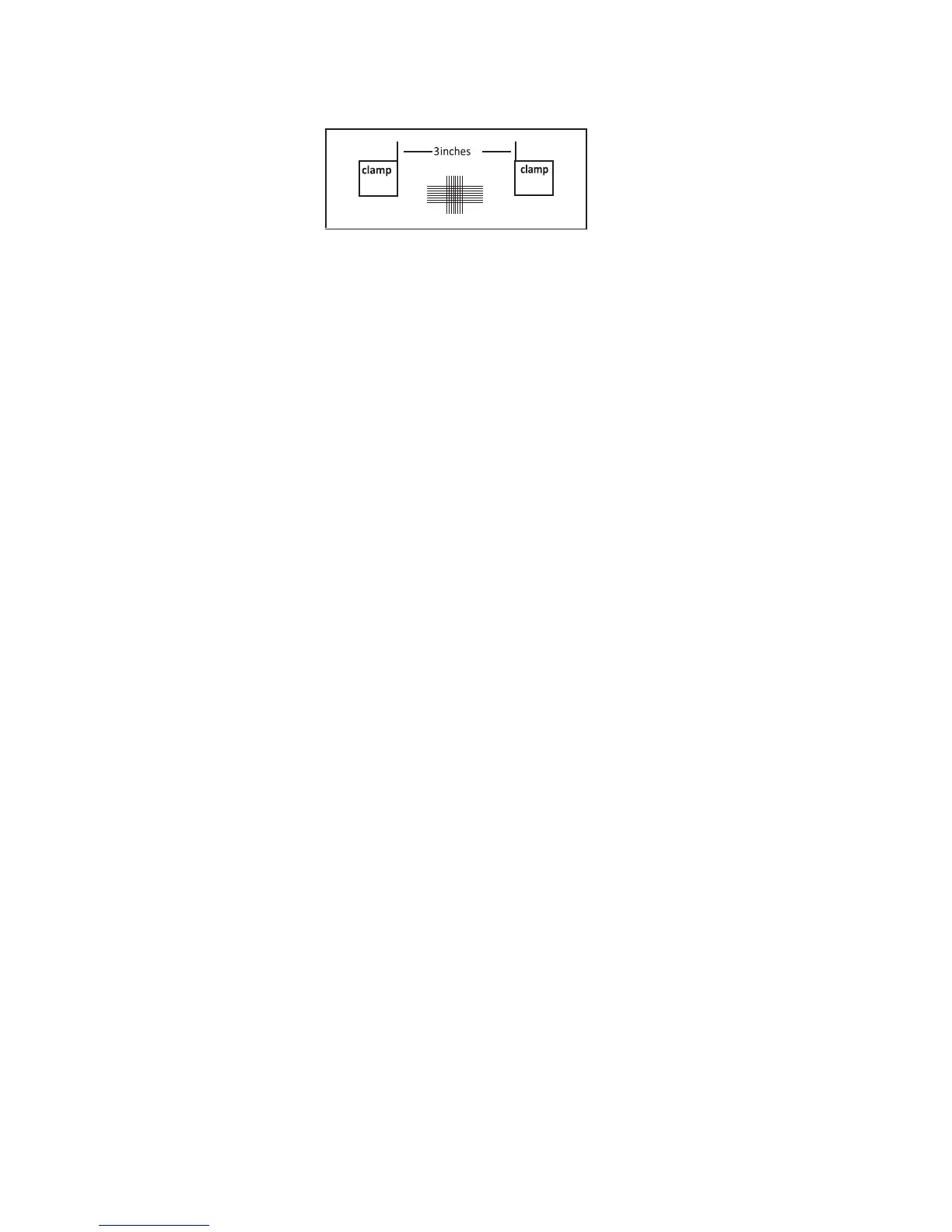

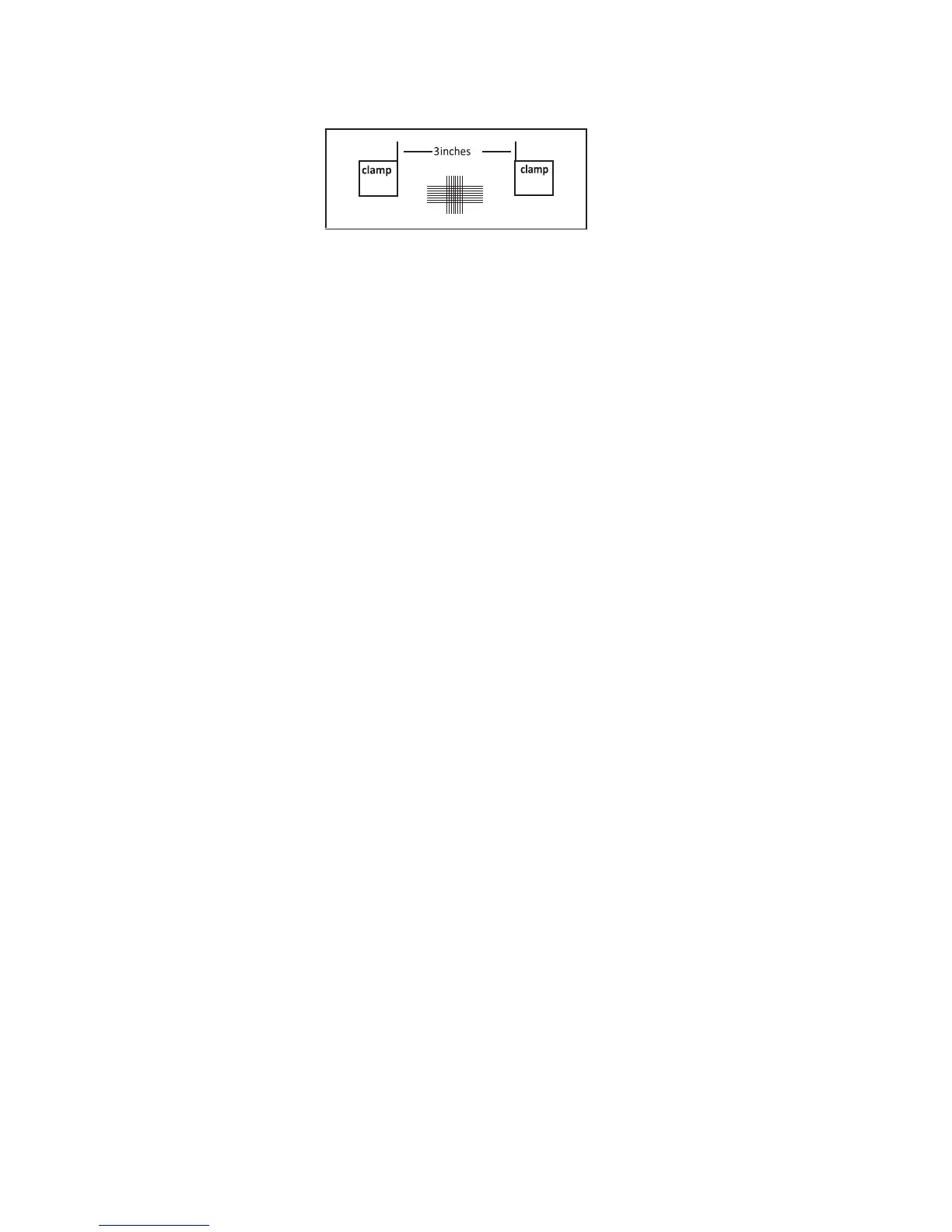

Pass the hook from the spring scale through the other eye and apply a 30 lb (13.62

Kg) load for 3 seconds.

APPLY TENSION PARALLEL TO WARP OR FILL (NOT ON THE BIAS)

PERMEABILITY CHECK:

The permeability of the fabric is very important. As the permeability increases, the canopy will

open more slowly and flight performance will deteriorate. The rate of descent will increase and

the forward speed will decrease. The ability of the canopy to flare to a soft landing will

decrease.

To help ensure opening, flight and landing performance maintained to a satisfactory level,

Performance Designs has established an average permeability limit of 8.0 cfm for the

top and bottom fabric surfaces.

Fabric permeability does not change while the canopy is packed; it changes as a result of use,

packing and handling. That’s why it is important to maintain a complete history of the

parachute.

Fabric permeability must be tested if any of the following events occur:

• The canopy is completely submerged in water.

• 25 jumps have been made on the canopy since it was new or last certified.

• The canopy has been repacked 40 times since it was new.

• The canopy has an unknown number of jumps, repacks, or there is reason to

believe that jumps or repacks were not properly logged.

•

Flight performance appears to be substandard.

• There are other reasons to believe the fabric permeability may exceed

specifications.

• The Performance Designs factory is equipped to perform permeability testing. It is

recommended that any canopy needing such testing be returned to the factory.

Loading...

Loading...