Warning!

Oil tool before each use. 4 to 5 drops of a good grade

Air Tool Oil placed in the air inlet is sufficient. Use prop-

er air pressure and CFM rating listed for this tool.

Drain water from hoses and compressor tank. Water in the air supply line

will cause gumming and loss of power. Clean the air lter on the supply

line and ush the tool with gum solvent or a 50/50 mix of air tool oil and

kerosene. It may be necessary to disassemble the tool to properly clean

and re-lubricate.

After each use, clean leftover grease from the Tube (18). Make sure the

Nozzle (10) and the tip of the Grease Gun are clear of dirt, grease, or

any debris. Wipe down the unit with a lint free cloth.

LUBRICATION & MAINTENANCE

OPERATION OPERATION OPERATION

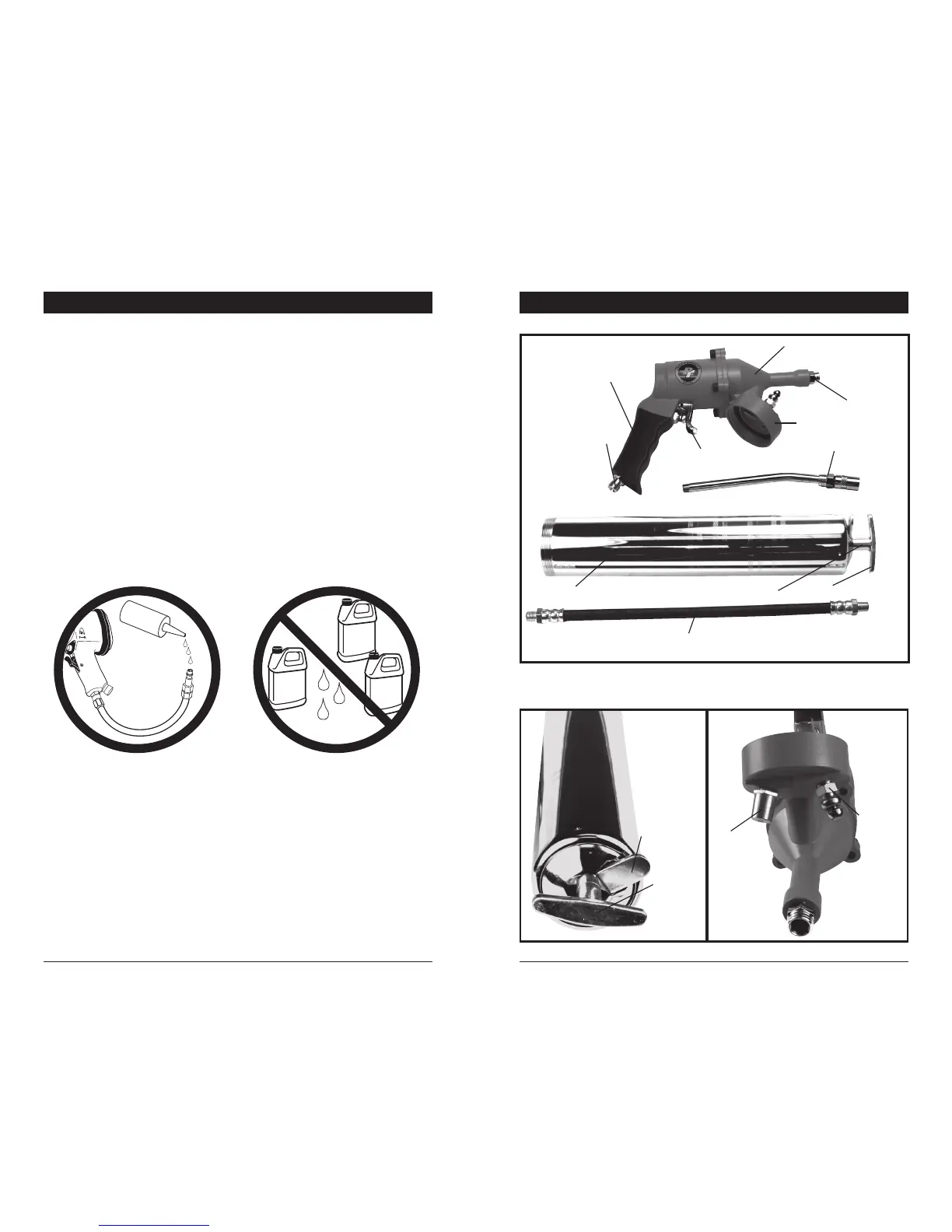

Finger Grip (1)

Air Fitting (2)

Trigger (3)

Front Housing (4)

House Cap (6)

Adaptor (5)

Bend Spout (7)

Top view of

Housing Cap (6)

Container Tube (8) Follower Rod (9)

Catch Plate (12)

Plunger Handle (10)

Plunger

Handle (10)

Air Vent

Valve (14)

Filler

Plug (13)

Flexible Hose Assembly (11)

(Not Included)

FIG. B

FIG. A

FIG. C

Loading...

Loading...