Page 29

OPERATION

CUTTING BASE MOLDING

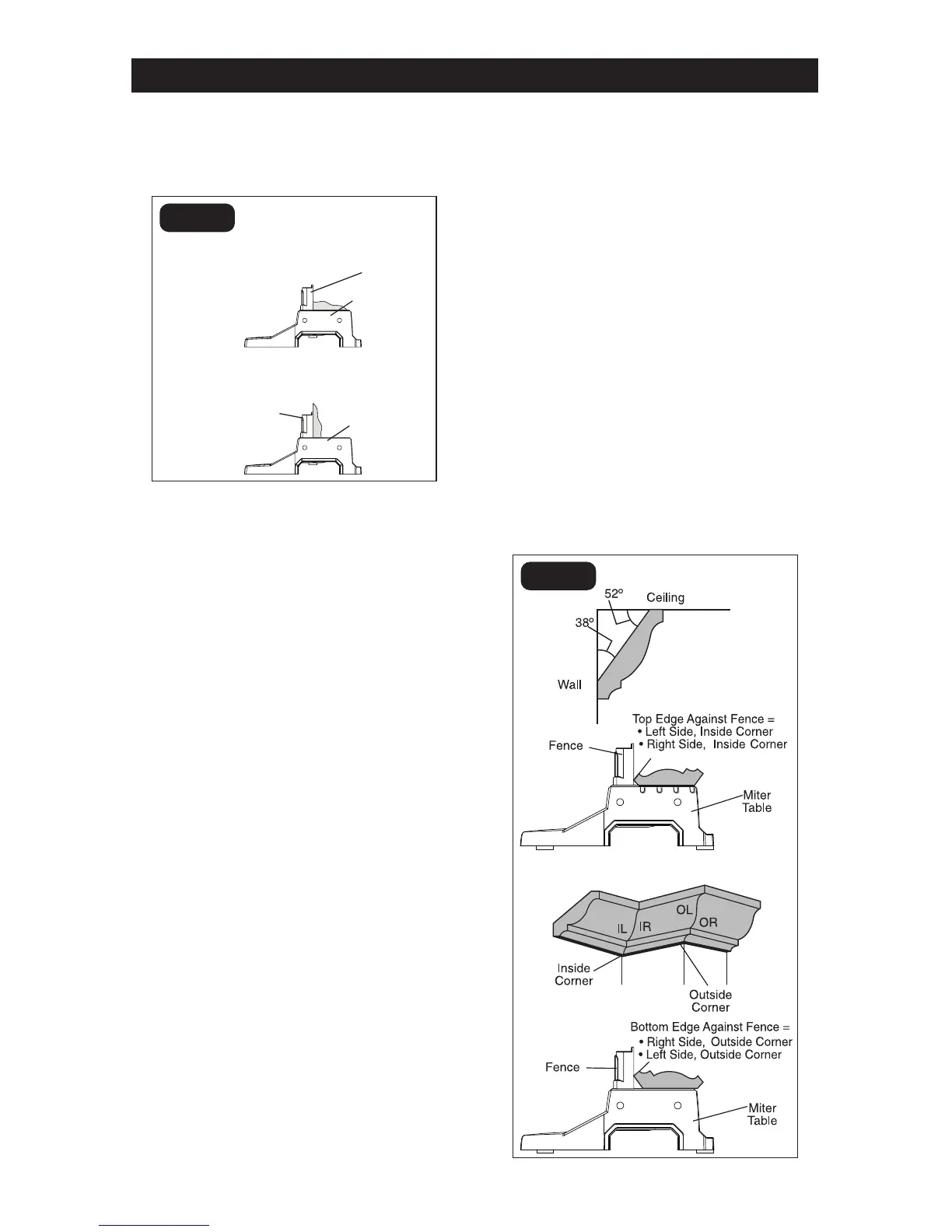

(FIG. 28)

Base moldings and many other moldings

can be cut on a compound miter saw. The

setup of the saw depends on the base

molding characteristics and applications.

Perform practice cuts on scrap materials

to achieve best result.

1. Always make sure moldings rest rmly

against the fence and table (Fig. 28).

Use the hold-down clamp provided or

C-clamps, and place tape on the area

being clamped to avoid marks on the

workpiece.

2. Reduce splintering by taping the cut

area prior to making the cut. Mark the

cut line directly on the tape.

3. Splintering typically occurs due to

incorrect blade style, a dull blade, a very

thin workpiece, or improperly dried

wood.

NOTICE: Always perform a dry run cut so

that you can determine whether the

operation being attempted is possible

before power is applied to miter saw.

FIG. 28

4. Place the workpiece at on the miter

table with one edge securely against the

fence. If the board is warped, place the

convex side against the fence. If the

concave edge of the board is against

the fence, the board could collapse on

the blade at the end of the cut and

jam the blade (Fig. 26 and 27).

5. Align the pencil line in the center of

the dual laser line.

6. Use the hold-down clamp to secure the

workpiece against the miter-saw table

and fence.

7. When cutting a long workpiece, use

extra support to hold the long workpiece.

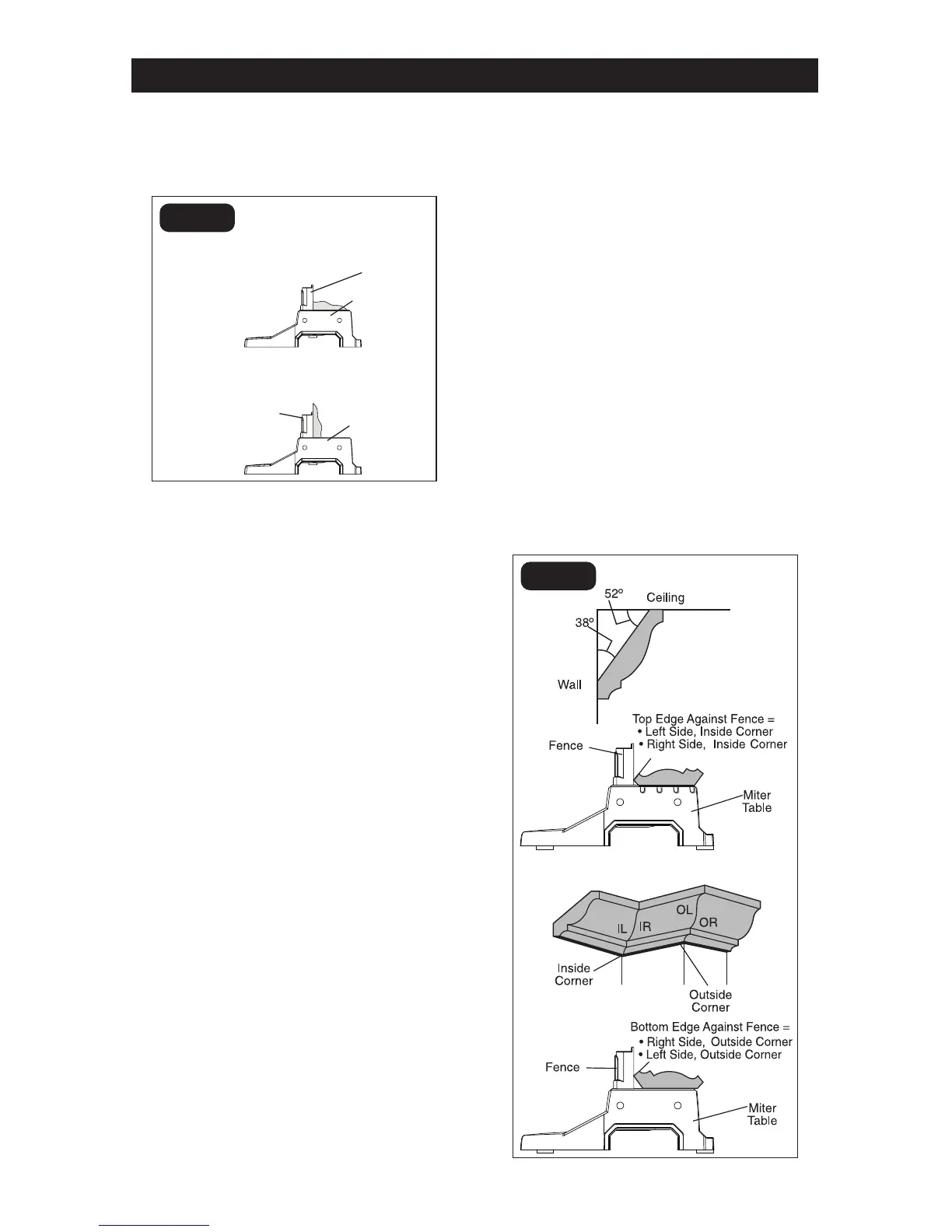

CUTTING CROWN MOLDING

(FIG. 29)

FIG. 29

Fence

Mitre at 0°,

Bevel at 45°

Mitre at 45°,

Bevel at 0°

Miter Saw

Fence

Miter Saw

Molding lying at on miter

table (before clamping)

Molding standing up against fence

(before clamping)

Loading...

Loading...