i08769663

Maintenance Section

Refill Capacities

Refill Capacities

Refer to this Operation and Maintenance Manual,

“Fluid Recommendations” for information about the

fluids which are acceptable for this engine.

Lubricant Refill Capacities

The refill capacities for the engine crankcase reflect

the approximate capacity of the crankcase or sump

plus standard oil filters. Auxiliary oil filter systems will

require more oil. Refer to the Original Equipment

Manufacturer (OEM) specifications for the capacity of

the auxiliary oil filter.

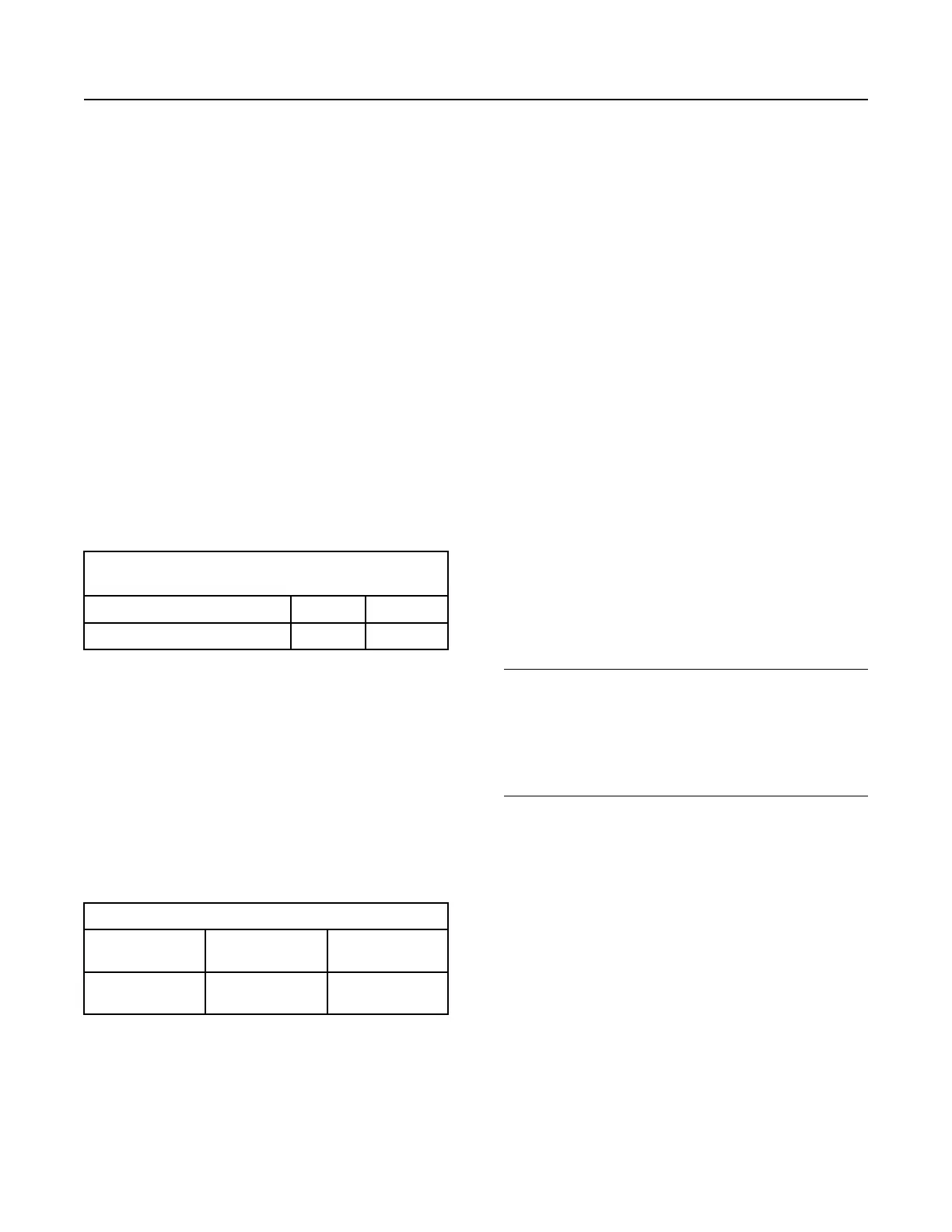

Table 3

1706 Industrial Engine

Approximate Refill Capacities

System

Liters

Quarts

Oil Sump

(1)

32 33.8

(1)

These values are approximate capacities for the crankcase oil

sump which include the standard oil filters that are installed at

the factory. Engines with auxiliary oil filters will require more oil.

Refer to the OEM specifications for the capacity of the auxiliary

oil filter.

Coolant Refill Capacities

To maintain the cooling system, the total cooling

system capacity must be known. The capacity of the

total cooling system will vary. The capacity will

depend on the size of the radiator (capacity). Table 4

should be completed by the customer for the

maintenance of the cooling system.

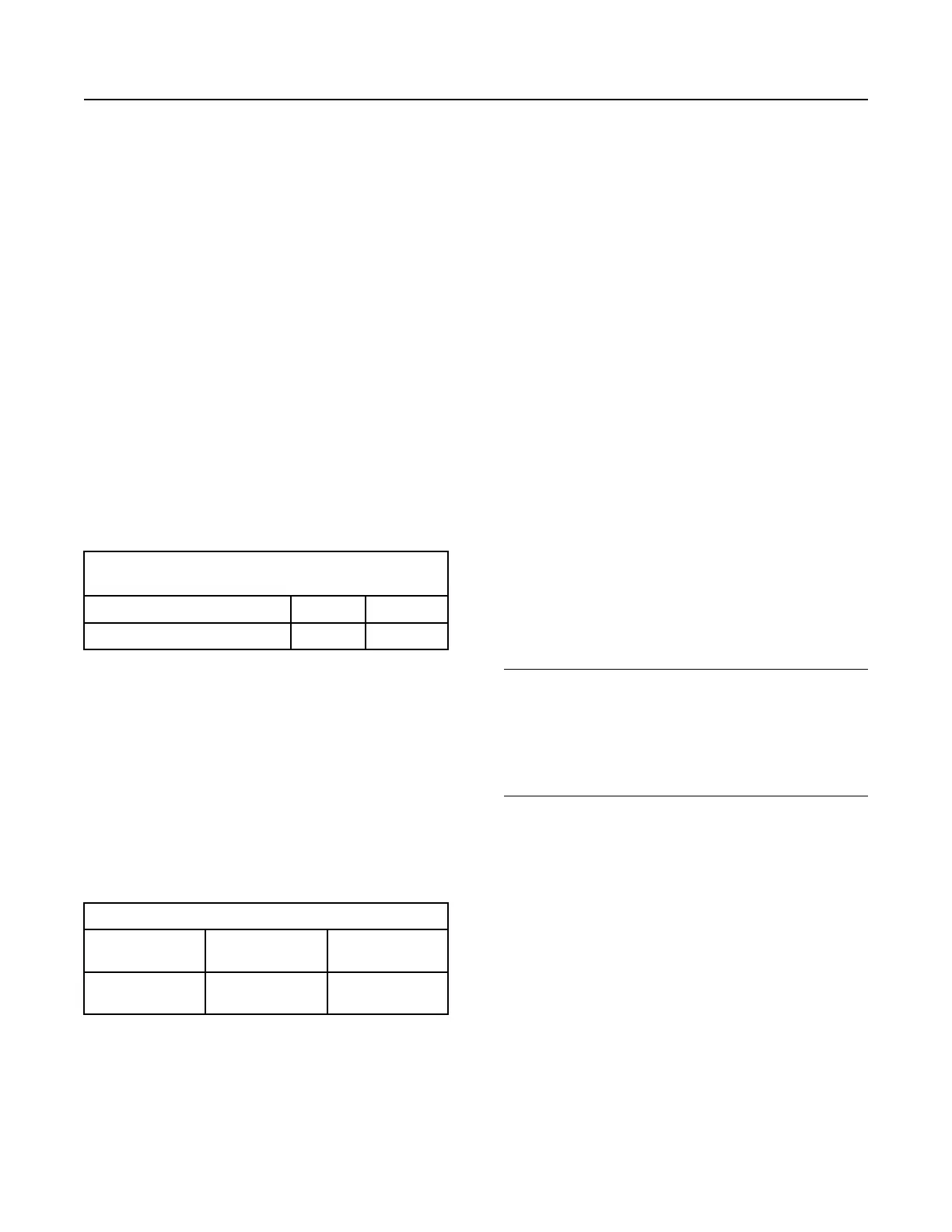

Table 4

Approximate Capacity of the Cooling System

Compartment or

System

Liters Quarts

Total Cooling Sys-

tem

(1)

(continued)

(Table 4, contd)

(1)

The total cooling system capacity includes the following compo-

nents: the engine block, the radiator, and all coolant hoses and

lines.

i07290436

Fluid Recommendations

(Diesel Exhaust Fluid (DEF))

General Information

Diesel Exhaust Fluid (DEF) is a liquid that is injected

into the aftertreatment system before Selective

Catalytic Reduction (SCR). This system of injecting

the DEF into the exhaust will reactor in the SCR

system.

In engines equipped with SCR emissions reduction

system, DEF is injected in controlled amounts into

the engine exhaust stream. At the elevated exhaust

temperature, urea in DEF is converted to ammonia.

The ammonia chemically reacts with NOx in diesel

exhaust in the presence of the SCR catalyst. The

reaction converts NOx into harmless nitrogen (N2)

and water (H2O).

Diesel Exhaust Fluid (DEF) is also known under

other names including Aqueous Urea Solution (AUS)

32,AdBlue, or generically referred to as urea.

NOTICE

Do not use agriculture grade urea solutions. Do

not use any fluids that do not meet “ISO 22241-1” Re-

quirements in SCR emissions reduction systems.

Use of these fluids can result in numerous problems

including damage to SCR equipment and a reduction

in NOx conversion efficiency.

DEF is a solution of solid urea that is dissolved in

demineralized water to produce a final concentration

of 32.5% urea. DEF concentration of 32.5% is

optimal for use in SCR systems. DEF solution of

32.5% urea has the lowest attainable freeze point of

−11.5° C (11.3° F). DEF concentrations that are

higher or lower than 32.5% have higher freeze

points. DEF dosing systems and “ISO 22241-1”

specifications are designed for a solution that is

approximately 32.5%.

Specification

DEF that is used in Perkins engines must meet the

ISO specification 22241-1 for quality. The ISO

specification 22241-1 requirements are met by many

brands of DEF, including those that carry the AdBlue

or API certification."

70 M0087475-06

Maintenance Section

Refill Capacities

Loading...

Loading...