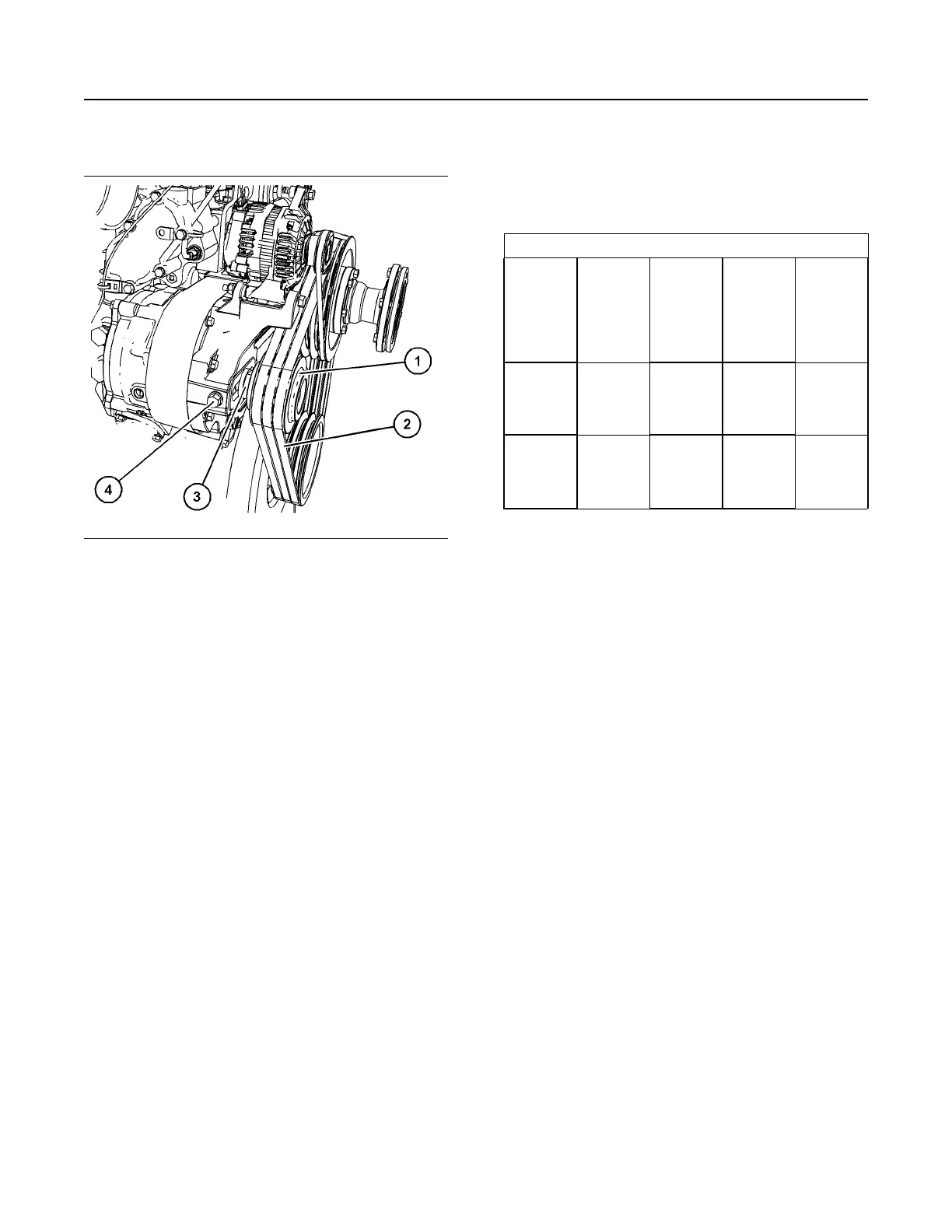

Fan Belt Adjustment

Illustration 66 g06109234

Typical example

1. Remove the belt guard, refer to OEM for the

correct procedure.

2. Loosen lock nut (3). Rotating nut (4) counter-

clockwise will move pulley (1) and loosen belts (2).

Rotating nut (4) clockwise will move pulley (1) and

tighten belts (2).

3. With the correct tension set, tighten nut (3).

Tighten nut (3) to a torque of 102 N·m (75 lb ft).

4. Use a suitable belt tension tool to set the belt

tension.

5. Reinstall the belt guard, refer to OEM for the

correct procedure.

If new drive belts are installed, check the drive belt

tension again after 30 minutes of engine operation

at the rated rpm.

Replace

For applications that require multiple drive belts,

replace the drive belts in matched sets. Replacing

one drive belt of a matched set will cause the new

drive belt to carry more load because the older drive

belts are stretched. The additional load on the new

drive belt could cause the new drive belt to fail.

To replace the alternator belt, refer to Disassembly

and Assembly, Alternator Belt - Remove and Install.

To replace the fan belts, refer to Disassembly and

Assembly, V-Belts- Remove and Install.

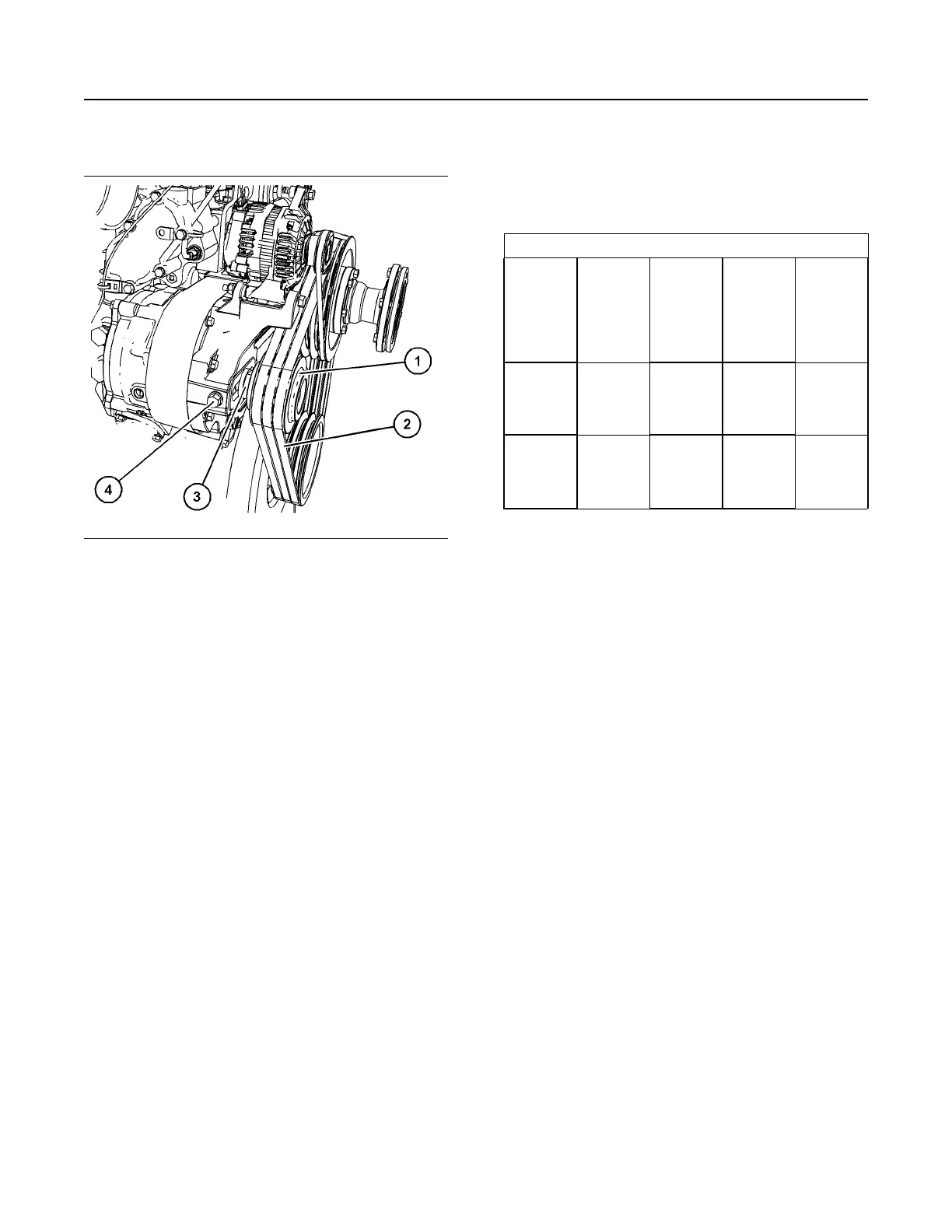

Belt Tension

Table 16

Alternator and Fan Belt Tension

Belt Type Belt Size New Belt

Tension

Used Belt

Tension

with fewer

than 10

Hours in

Operation

Reset Belt

Tension

Alternator

belt

10 mm

(0.39370

inch)

645 ± 44

N

(145 ± 10

lb)

512 ± 44

N

(115 ± 10.

lb)

311 ± 44

N

(70 ± 10

lb)

Fan Belt 5V/5VX

15 mm

(0.59055

inch)

801 ± 44

N

(180 ± 10

lb)

645 ± 44

N

(145 ± 10

lb)

378 ± 44

N

(85 ± 10

lb)

Note: Do not set the belt tension when the belts are

hot.

i06942621

Belts - Inspect/Replace

(General Information for Poly

Vee Belts)

The polly vee belt may also be called the micro rib

belt.

M0076814-03 83

Maintenance Section

Belts - Inspect/Replace

Loading...

Loading...