PART 8: MAINTENANCE AND SERVICE

PB1319 (CAT. NO. 5296 ) —129— 22-01691 (R02/02)

If you have manual slack adjusters:

• Adjust the slack adjuster until the brake is tight.

• Then back off two or three clicks until the shoes are just free. You

can determine this by spinning the wheel or tapping on the drum

and listening for a clear ringing sound.

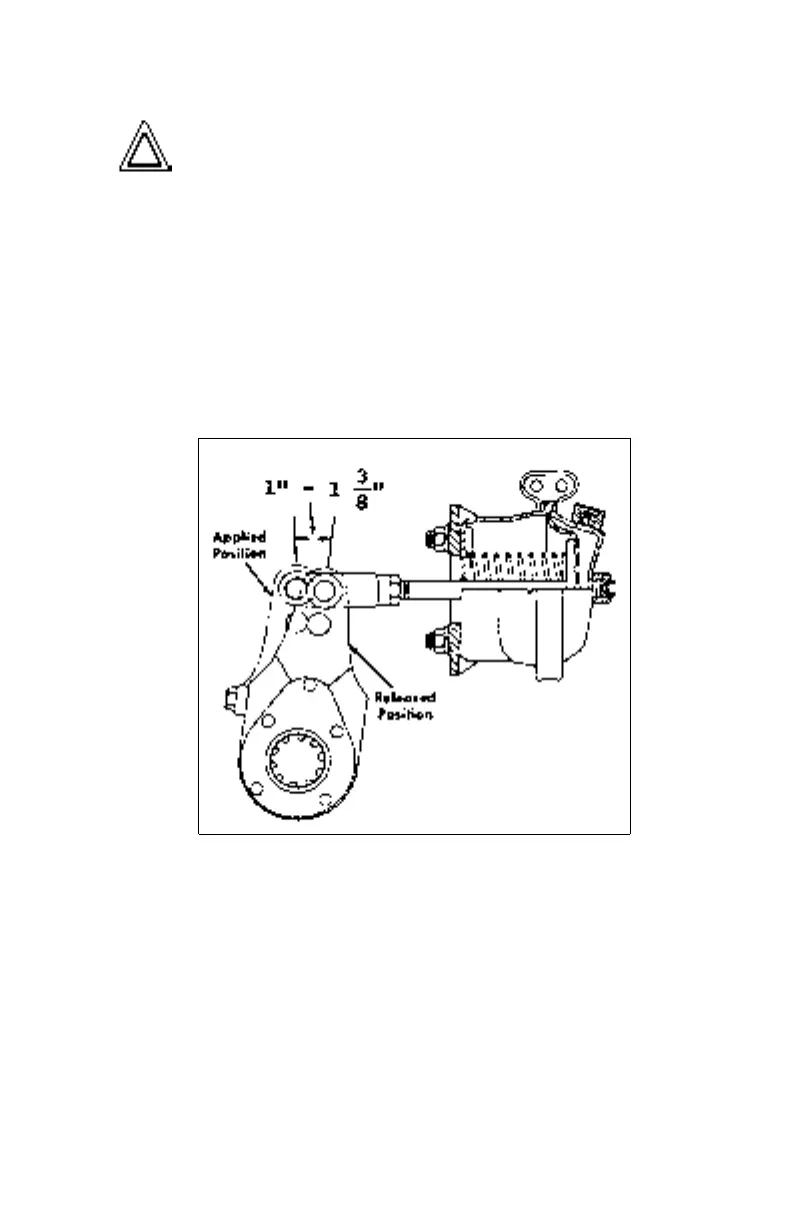

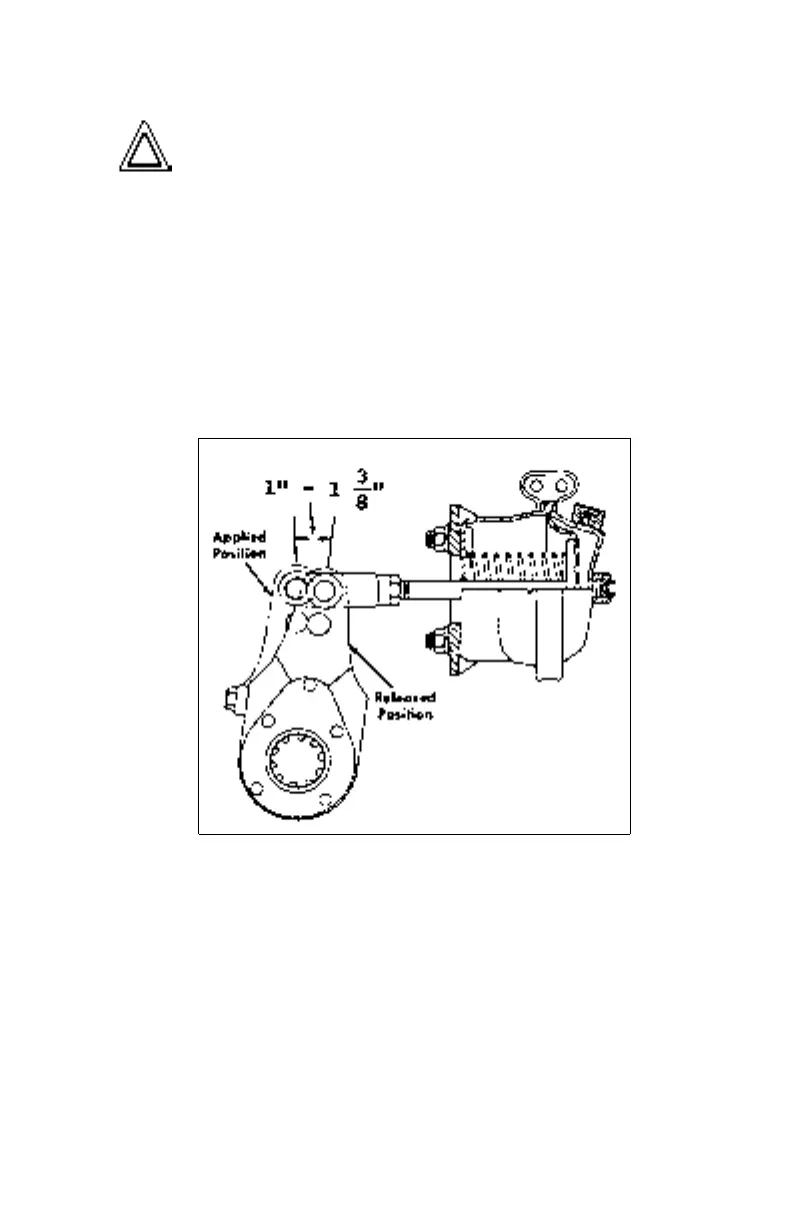

Normal pushrod travel is about 1 to 1 3/8 inch front and rear after

brakes have been properly adjusted.

Correct Pushrod Travel

If you have automatic slack adjusters: Constant manual adjustment of

automatic slack adjusters can shorten the life of your internal clutch.

If proper stroke cannot be maintained, replace the slack adjuster.

Operational Checks of Automatic Slack Adjusters

• Measure brake chamber stroke with the spring brake released and

the air pressure at 100 psi (690 kPa) minimum. Correctly installed

and functioning auto slack will produce the following strokes:

Type 36 chamber (rear brakes) should have a 1 1/2 inch to 2 1/4

inch (38 mm to 57 mm) stroke.

Type 30 chamber (rear brakes) should have a 1 1/2 inch to 2 inch

(38 mm to 51 mm) stroke.

CAUTION: The brake adjuster alone does not ensure

proper brake operation. Inspect all brake components. All

brake components work together and must be checked

periodically to ensure the brake system works properly.

See the Peterbilt Master Maintenance Manual for more

information on brake maintenance.

02945

Loading...

Loading...