PART 8: MAINTENANCE AND SERVICE

PB1319 (CAT. NO. 5296 ) —154— 22-01691 (R02/02)

Belt Tension

Alternator drive belts (all widths), new or used, should be adjusted to

105-125 pounds (467-566 N.) of tension.

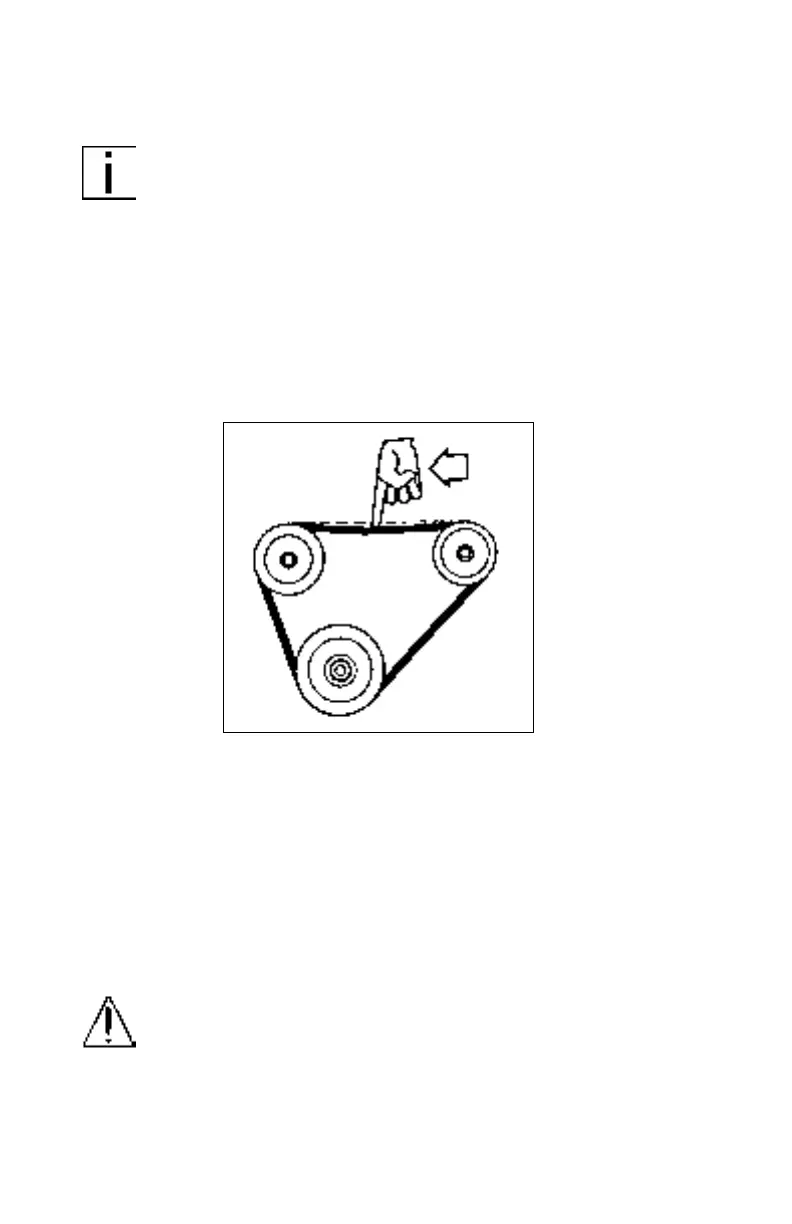

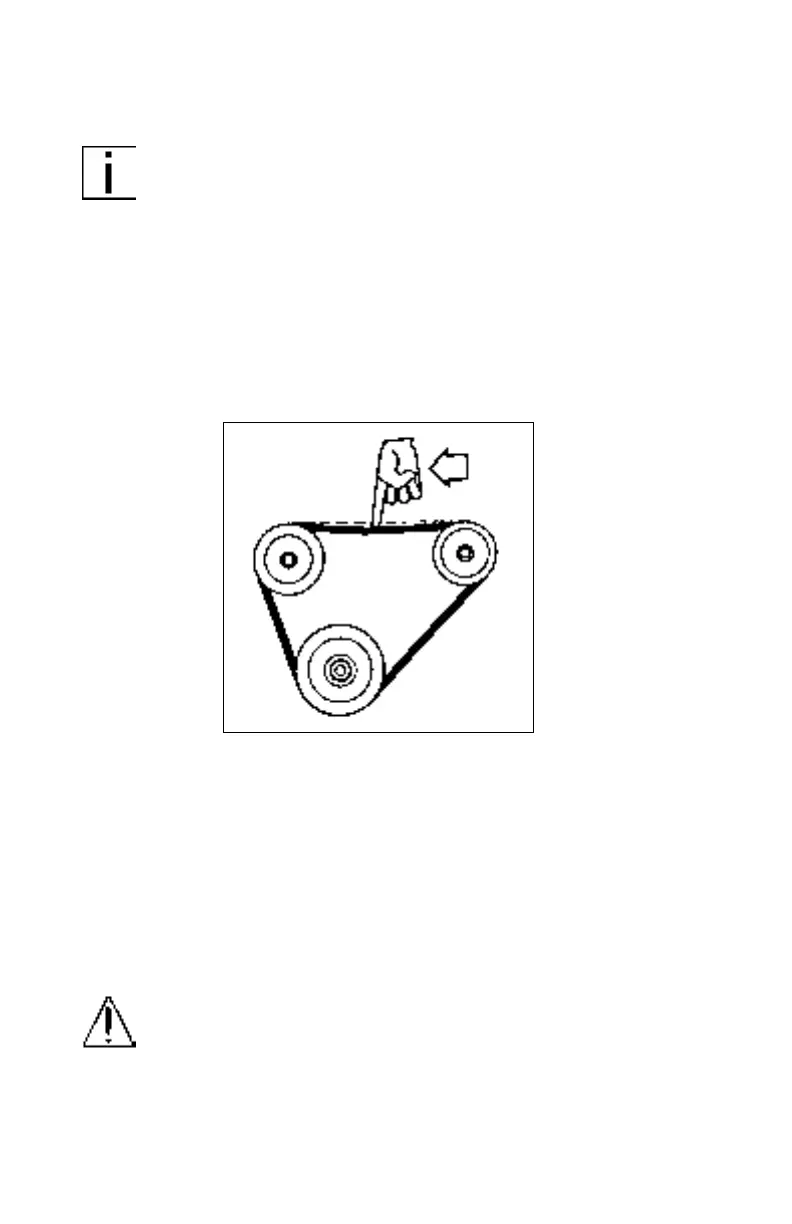

The best method of testing belt tension is to apply a good quality

commercial gauge. If a tension gauge is not available, use this

method of testing:

• Apply 25 pounds (111 N.) of force midway between the pulleys.

• Deflection should be one belt thickness for each foot of distance

between the pulley centers.

Tension Test

Retensioning New Belts

A belt is considered “used” after 30 minutes of operation. New belts

will loosen after running for an hour or more. Check for proper ten-

sion after the first period of operation. If the belt can be deflected 1/8

in. (3 mm) more than specified above, tighten according to the section

above on belt tension. Do not tighten belts beyond specified limits.

Damage to bearings and the belts may occur.

Fan Clutch / Fan

To Check Your Fan:

1. Check the fan assembly mounting bolts for tightness. Inspect the

blades for damage.

NOTE: Engines equipped with poly-vee belts are equipped

with tensioners and therefore require no belt adjustments.

WARNING! Thermatic fans engage suddenly without

warning and can hurt you badly. Stay away from the fan

when the engine is running.

02953

Loading...

Loading...