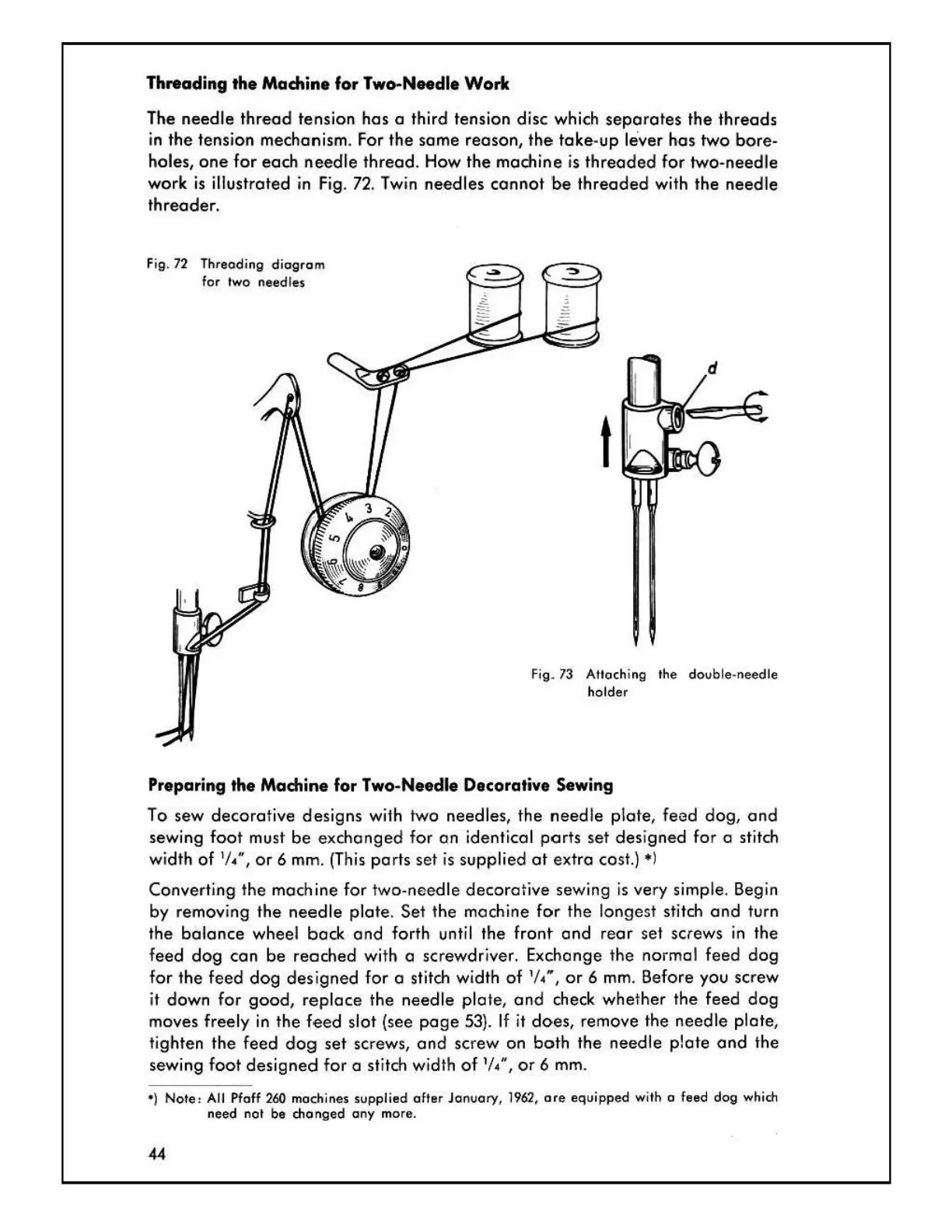

Threading the Machine

for

Two-Needle

Work

The needle

thread

tension

has

a third tension disc which

separates

the

threads

in

the

tensi

on

mechanism. For

the

same

reason,

the

take

-up lever

has

two bore-

holes,

one

for

each

needle

thread.

How

the

machine is

threaded

for two-needle

work

is

illustrated

in

Fig.

72.

Twin needles

cannot

be

threaded

with the needle

threader.

Fig.

72

Th

reading

di

ogrom

for two needles

-€

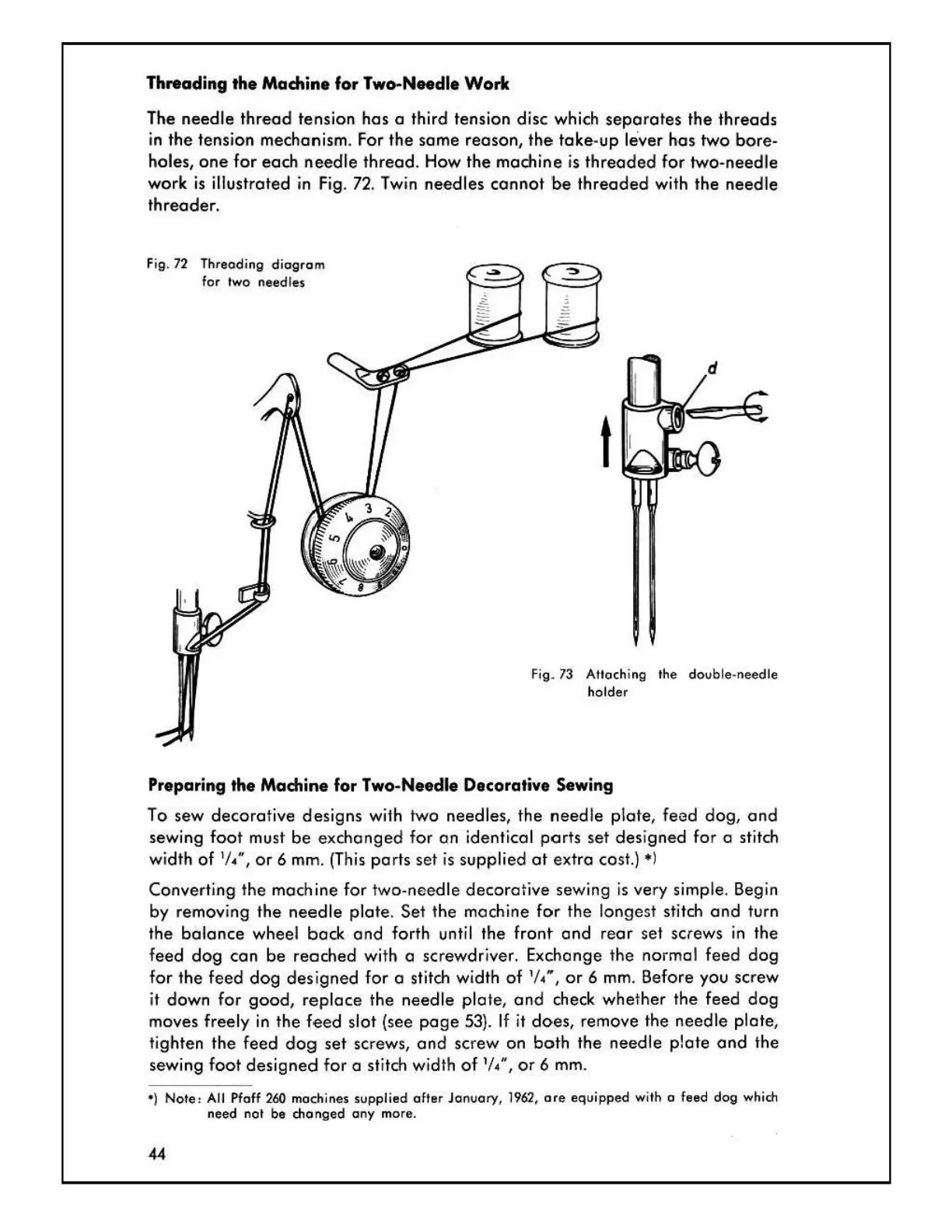

Fi

g.

73

Attaching the

do

uble-needle

hol

de

r

Preparing the Machine for Two-Needle Decorative Sewing

To sew

decorative

designs with two needles,

the

needle

plate,

f

eed

dog,

and

sewing

foot

must

be

exchanged

f

or

on

identical ports

set

designed for a stitch

width

of

1

/

/'

,

or

6 mm.

{This

ports set is supplied

at

extra

co

s

t.)

*)

Converting the machine for two-needle

decorative

sewing is very simple. Begin

by removing

the

needle

plate

. Set the machine

for

the longest stitch

and

turn

the

balance

whee

l bock

and

forth until

the

front

and

rear

set screws

in

the

feed

dog

con

be

reached

with a screwdriver. Exchange the normal feed

dog

for

the

feed

dog

designed

for

a stitch width

of

1

/4",

or

6

mm.

Before you screw

it down

for

good,

replace

the

needle

plate,

and

check whether

the

feed

dog

moves freely

in

the

feed

slot {see

page

53).

If

it

does

, remove the

needle

plate,

tighten the f

eed

dog

set

screws,

and

scr

ew

on

both

the needle p!ote

and

the

sewing

foot

designed

for a stitch width

of

1

//',

or

6

mm.

•) Note: All Pfaff

260

machines suppli

ed

af

t

er

Ja

nuary,

1962

,

ore

equ

i

pped

with o f

eed

dog

whi

ch

need not be

changed

any

more.

Loading...

Loading...