Exchanging

the

Sewing

Hook

in

the

Pfaff

360

If

it should become necessary to replace a

dama~ed

sewing hook, hold the

balance

wheel, pass a screwdriver through

the

aperture

at

the back

of

the

cylinder arm,

and

take

out

screw a

(Fig

.

85)

. Turn the screwdriver clockwise

because

this screw has left-hand thread. Nex

t,

remove

the

position finger

bracket,

and

cautiously pull the hook with the hook

shaft

out

of

the machine.

Make sure though

that

you remember the position

of

the sewing hook

in

the

machine.

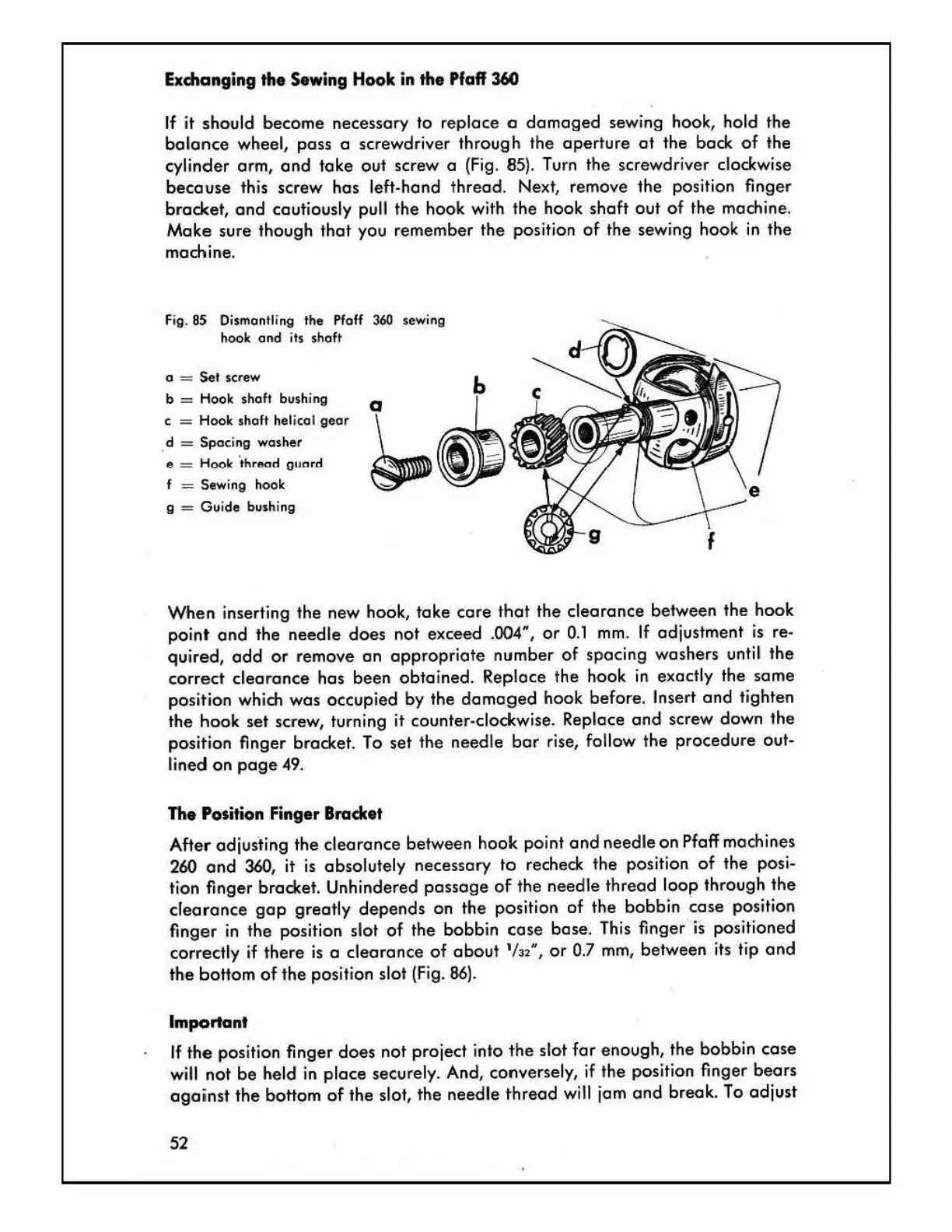

Fig. 85 Dismantling the Pfaff

360

sewing

hook

and

its

shaft

o = Set screw

b

= Hook shaft bushing

c = Hook shaft helical

gear

. d = Spacing washer

e =

Hook

'thrl!!od

gunrd

f = Sewing hook

g

=

Gu

i

de

bushing

When

inserting the new hook, take

care

that

the

clearance

between the hook

point

and

the needle does not exceed .004",

or

0.1

mm.

If

adjustment is re-

quired,

add

or

remove

an

appropriate

number

of

spacing washers until the

correct

clearance

has

been

obtained. Replace the hook in exactly

the

same

position which was occupied by the

damaged

hook before. Insert

and

tighten

the

hook set screw, turning it counter-clockwise. Replace

and

screw down the

position finger bracket. To set the

needle

bar

rise, follow the procedure out-

lined

on

page

49.

The

Position

Finger

Bracket

After adjusting

the

clearance between hook point

and

needle on Pfaff machines

260

and

360, it

is

absolutely necessary

to

recheck

the

position

of

the posi-

tion finger bracket. Unhindered

passage

of

the

needle thread loop through

the

clearance

gap

greatly

depends

on

the

position

of

the bobbin case position

finger

in

the position slot

of

the bobbin

case

base. This finger is positioned

correctly

if

there

is

a

clearance

of

about

1

/n",

or

0.7

mm,

between its tip

and

the

bottom

of

the

position slot

(F

ig.

86).

Important

If

the

position finger

does

not project into

the

slot

far

enough,

the

bobbin

case

will not

be

held

in

place securely. And, conversely, if the position finger bears

aga

inst

the

bottom

of

the slot,

the

needle

thread

will

jam

and

break

. To adjust

52

Loading...

Loading...