Fig.

95

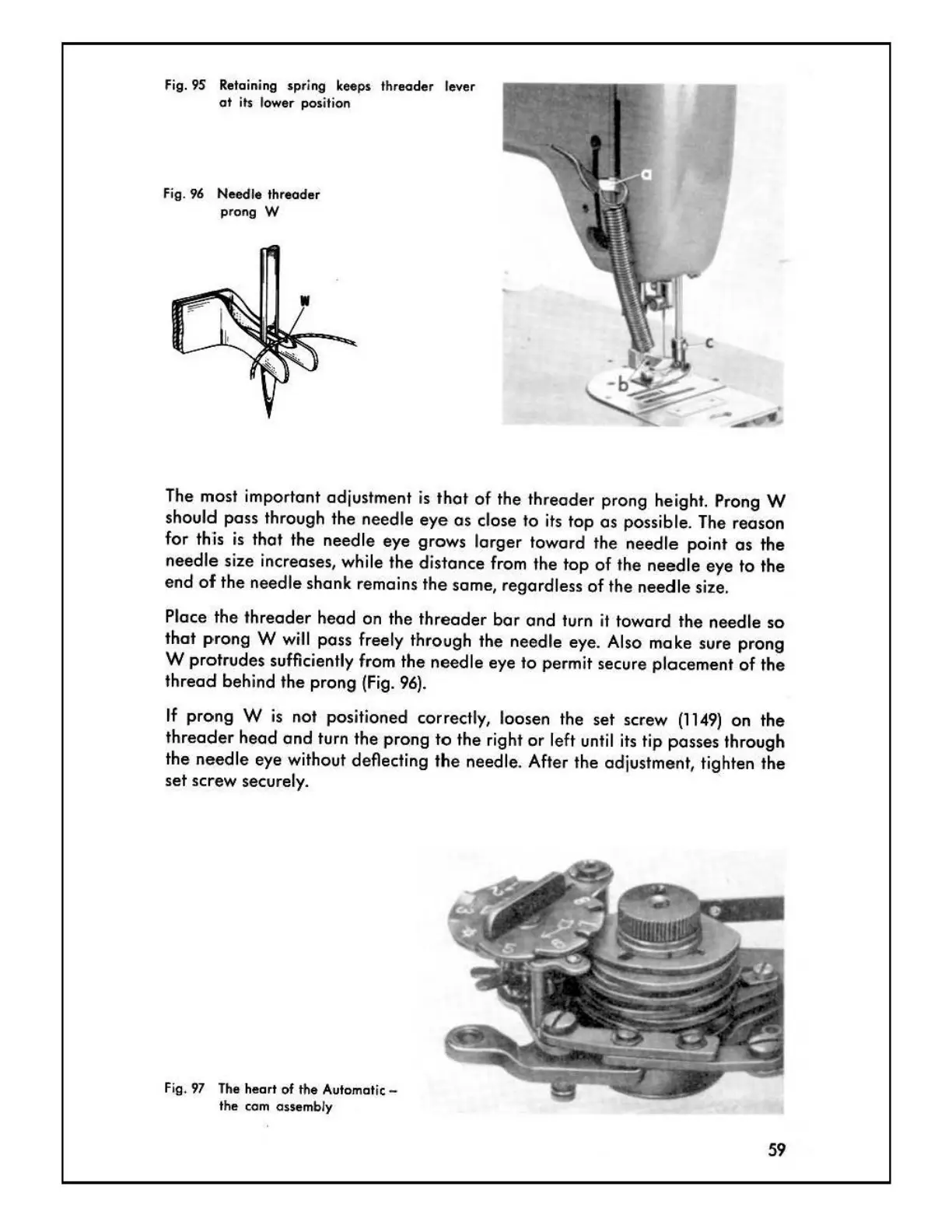

Retaining spring keeps threader l

ever

at

its lower position

Fig.

96

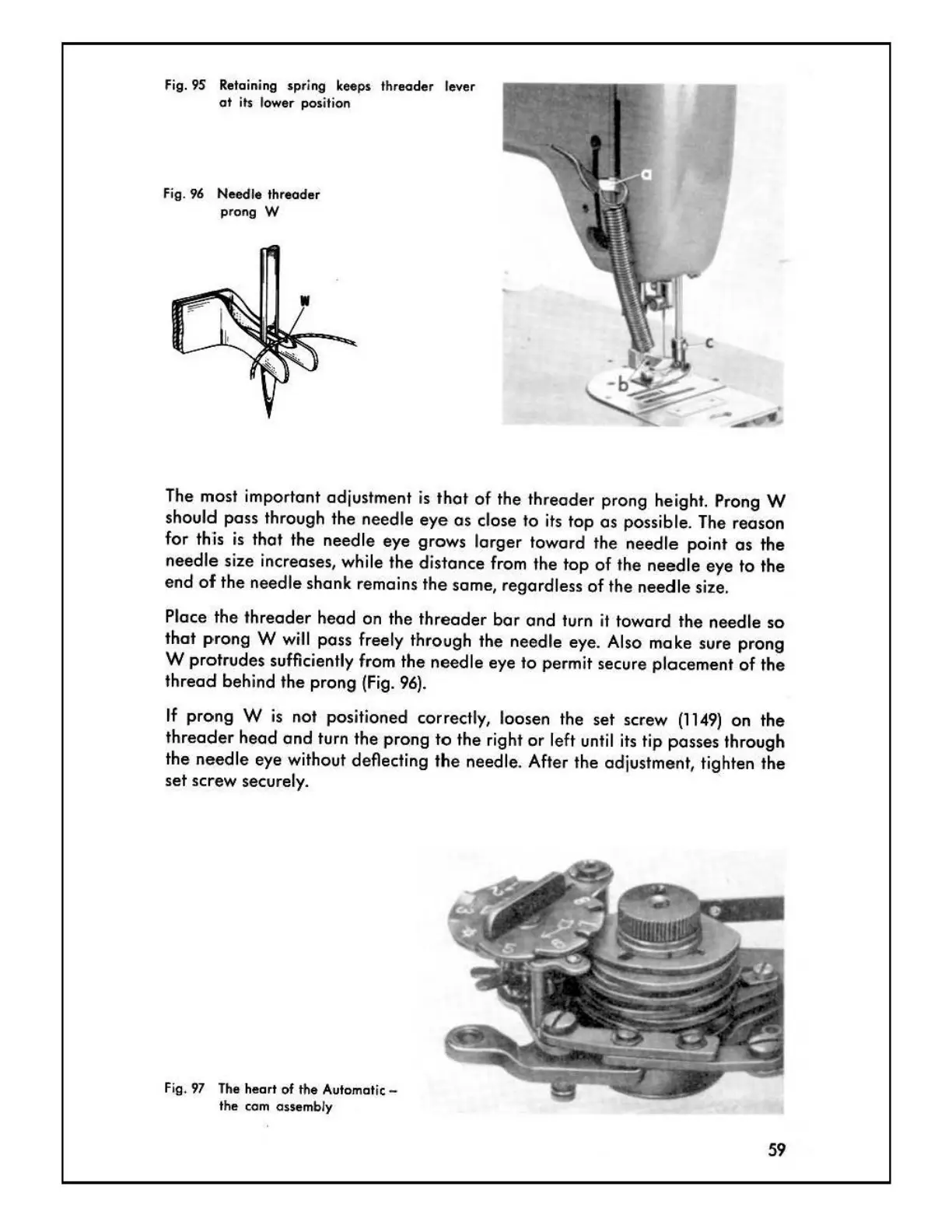

Needle threader

prong W

The most important adjustment is

that

of

the threader prong height. Prong W

should pass through the needle

eye

as

close to its top

as

possible. The reason

for this

is

that the needle

eye

grows larger toward the needle point

as

the

needle size increases, while

the

distance from the top

of

the needle eye

to

the

end

of

the needle shank remains

the

same, regardless

of

the needle size.

Place

the

threader

head

on the

threader

bar

and

turn

it

toward the needle

so

that

prong

W will pass freely through the needle eye. Also make sure prong

W protrudes

sufficiently from

the

needle eye to permit secure plocement

of

the

thread

behind the prong

(Fig.

96}.

If

prong W

is

not positioned correctly, loosen the set

scr.ew

(1149)

on

the

threader

head

and

turn the prong

to

the

right

or

left until its tip posses through

the

needle eye without deflecting

the

needle. After the adjustment, tighten the

set screw

securely.

Fig.

97

The heart

of

the

Automatic-

the com assembly

59

Loading...

Loading...