12

Adjustment

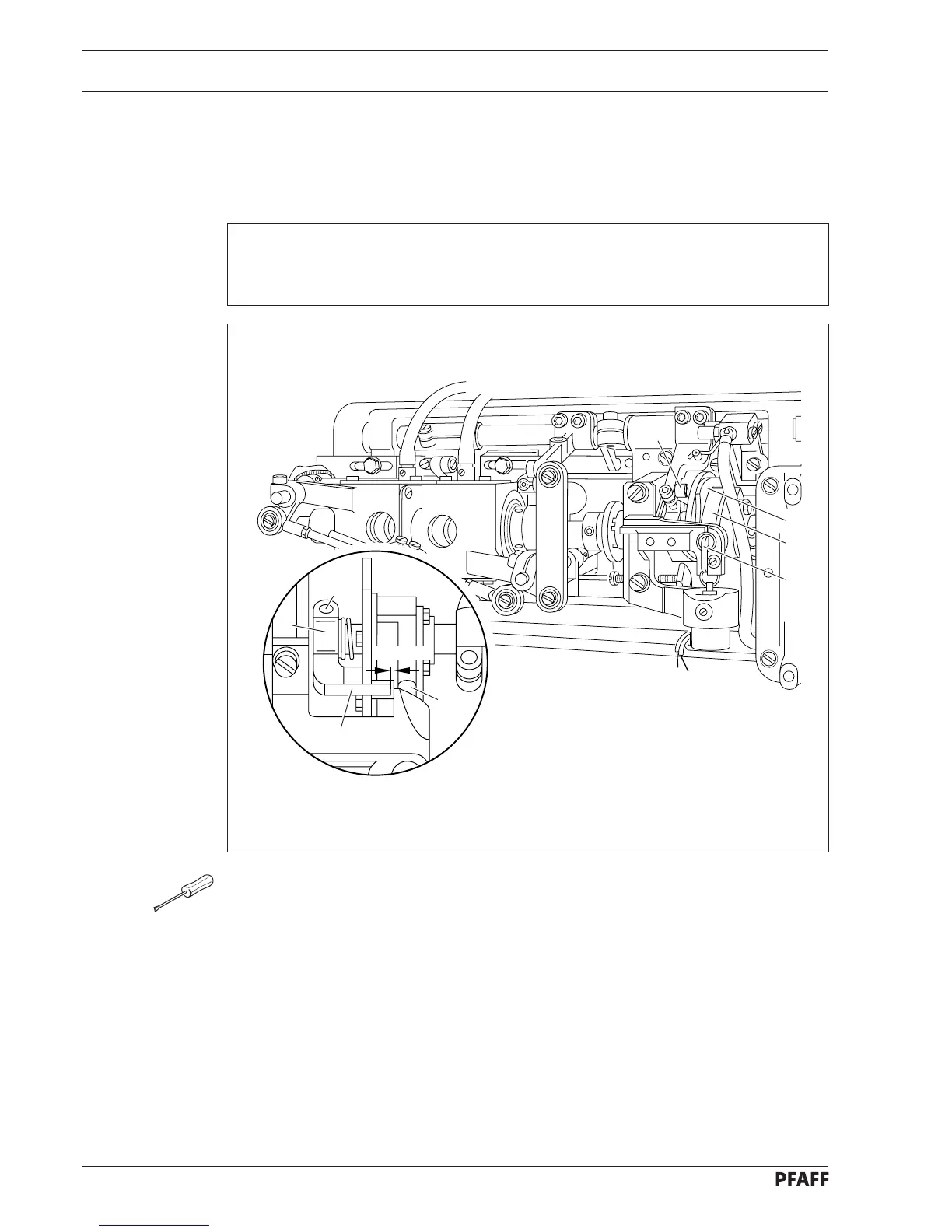

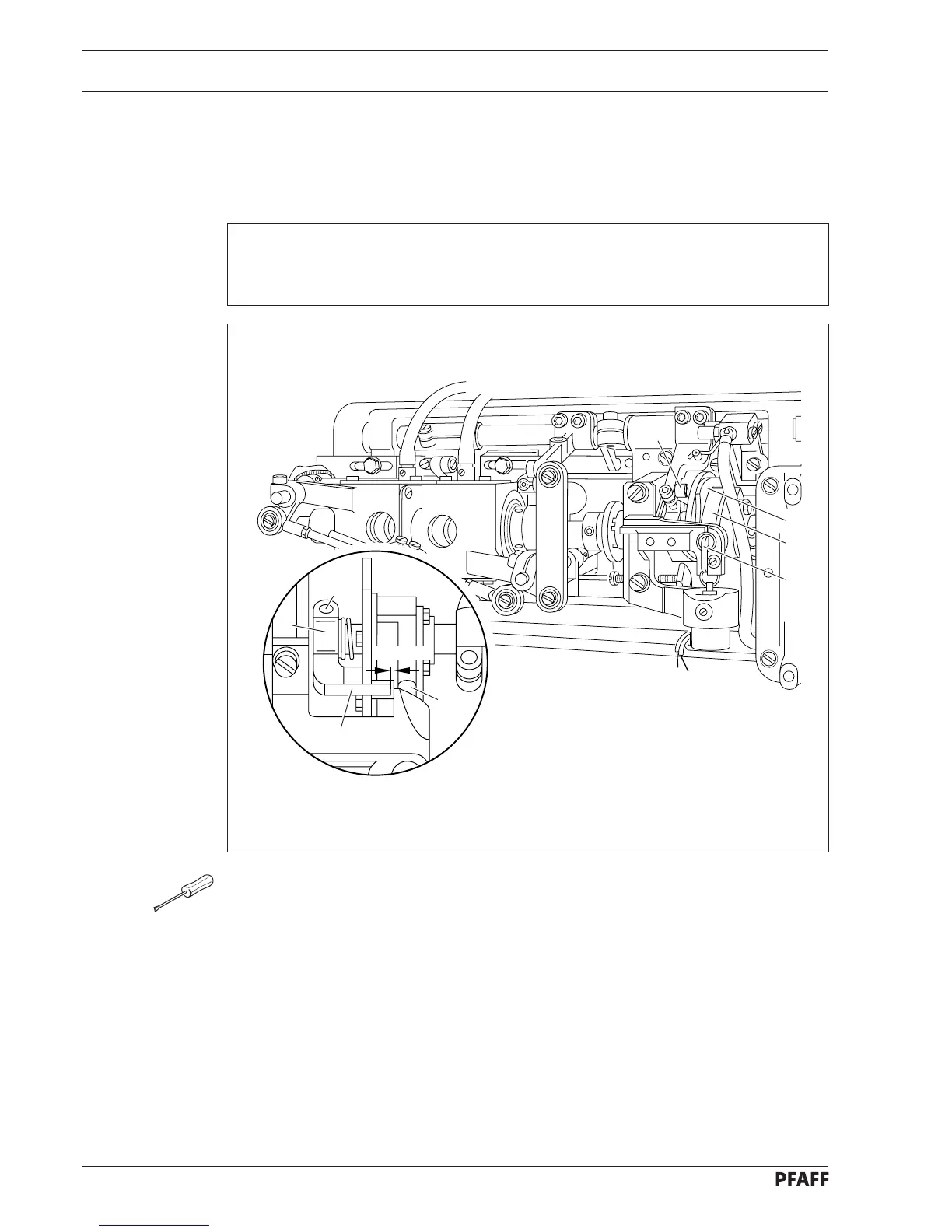

7 Control cam and locking bracket

7.01 Axial position of crank lever

● Turn balance wheel in feeding direction until needle bar is positioned 10 mm before b.d.c.

● Loosen screw 1 just sufficiently for crank lever 2 to be moved on its shaft against

resistance.

● Operate engaging lever 3.

● Continue turning balance wheel until control pin 4 has set control cam 5 at its left point of

reversal.

● Retain this position, then move crank lever 2 laterally according to the requirement.

● Turn balance wheel in feeding direction until needle bar is positioned 10 mm before b.d.c.

● Tighten screw 1.

● Make sure control cam 5 is just about to snap back to starting position, then push it all

way to left. As you continue turning balance wheel, return motion cam 6 must freely pass

stud 7.

If required, repeat solenoid bracket adjustments (chap.4).

7

6

5

3

1

2

8

4

0.2 mm

Requirement

Operate engaging lever 3 and turn the balance wheel to set control cam 5 at its far left

position; there must then be a clearance of 0.2 mm between guide finger 8 and bottom of

the control cam cutout (see below).

Loading...

Loading...