Operating Manual DTS and DTI 6201C / 6301C Multi-Controller (MC) 086100014 © Pfannenberg GmbH Page 39 / 43

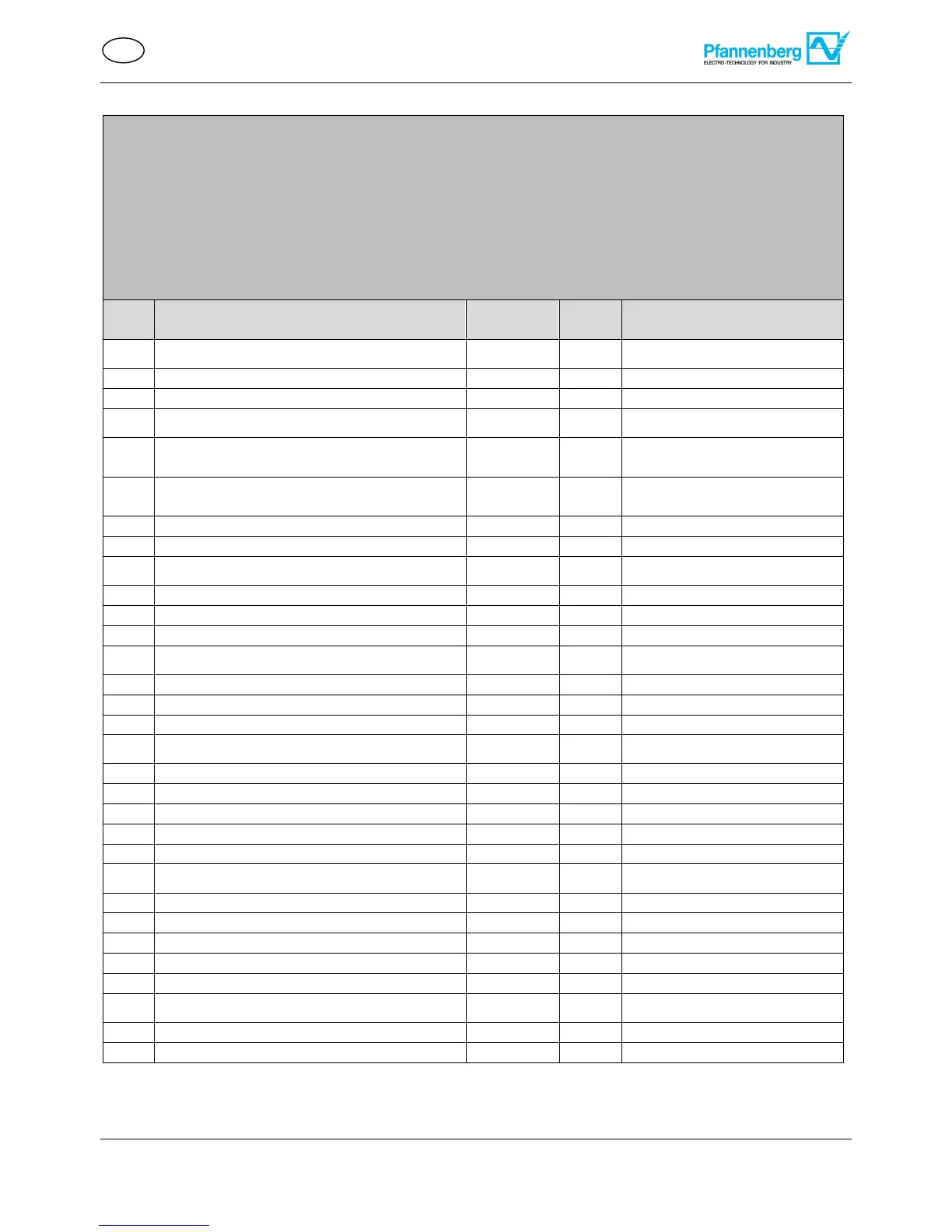

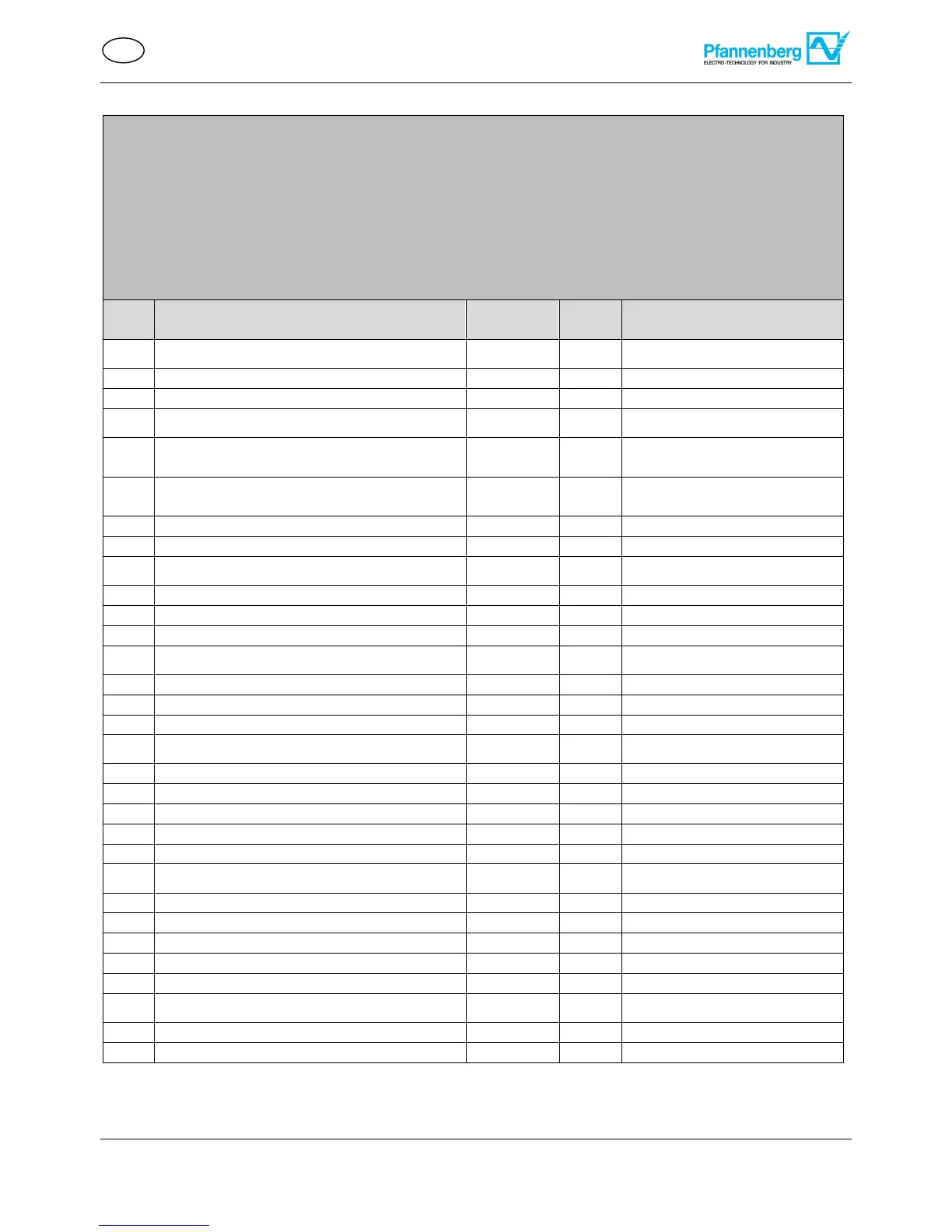

5.5 Maintenance checklist template

Cooling unit maintenance checklist

Maintenance interval: Conduct maintenance every twelve months.

Conduct maintenance every two to six months in

oil- and dust-laden environmental air.

Type:

Serial number:

Date of maintenance:

Technician carrying out the work (name):

Unit range designation/

Required maintenance tasks

Aggregate before maintenance

General visual inspection of the aggregate

Inspection for corrosion damage

Inspect refrigerant-carrying parts for traces of

oil

Inspect refrigerant-carrying parts for leak

tightness

Inspect electrical connections for damage

Inspect evaporator for ice formation

Condenser / heat exchanger

Inspect pipe package for deposits

Inspection for general corrosion damage

Inspect, clean, align fins*

Evaporator / heat exchanger

Inspect pipe package for deposits

Inspection for general corrosion damage

Inspect, clean, align fins*

Inspect mount for loose parts

Inspect the electrical connection for damage

Check motor bearings for noises

Check the drive for signs of overheating

Evaporator fan (internal)

Inspect mount for loose parts

Inspect the electrical connection for damage

Check motor bearings for noises

Check the drive for signs of overheating

* Maintenance intervals are more frequent, depending on the degree of contamination.

Loading...

Loading...