www.phenomenex.com

1

© 2009 Phenomenex, Inc. All rights reserved.

A. Capillary GC Installation with a Traditional GC Nut

Note: GC columns do not have a specific directional flow when received from the manufacturer. Upon initial use of your new Zebron

™

column, Phenomenex recommends

the practice of dedicating one specific end of the column for injector installation only. This is particularly important when dealing with active/caustic or contaminating

compounds. If these compounds are routinely injected onto the column, degradation of the phase will occur - leading to higher bleed. A typical first step to remedying

(removing) this bleed would be to trim 10 cm from the front (injector) end of the column and keep trimming this inlet end of the column as necessary. Trying to remedy any

bleed issues by trimming the column may not work if both ends have been interchangeably installed into the inlet.

Injector Installation

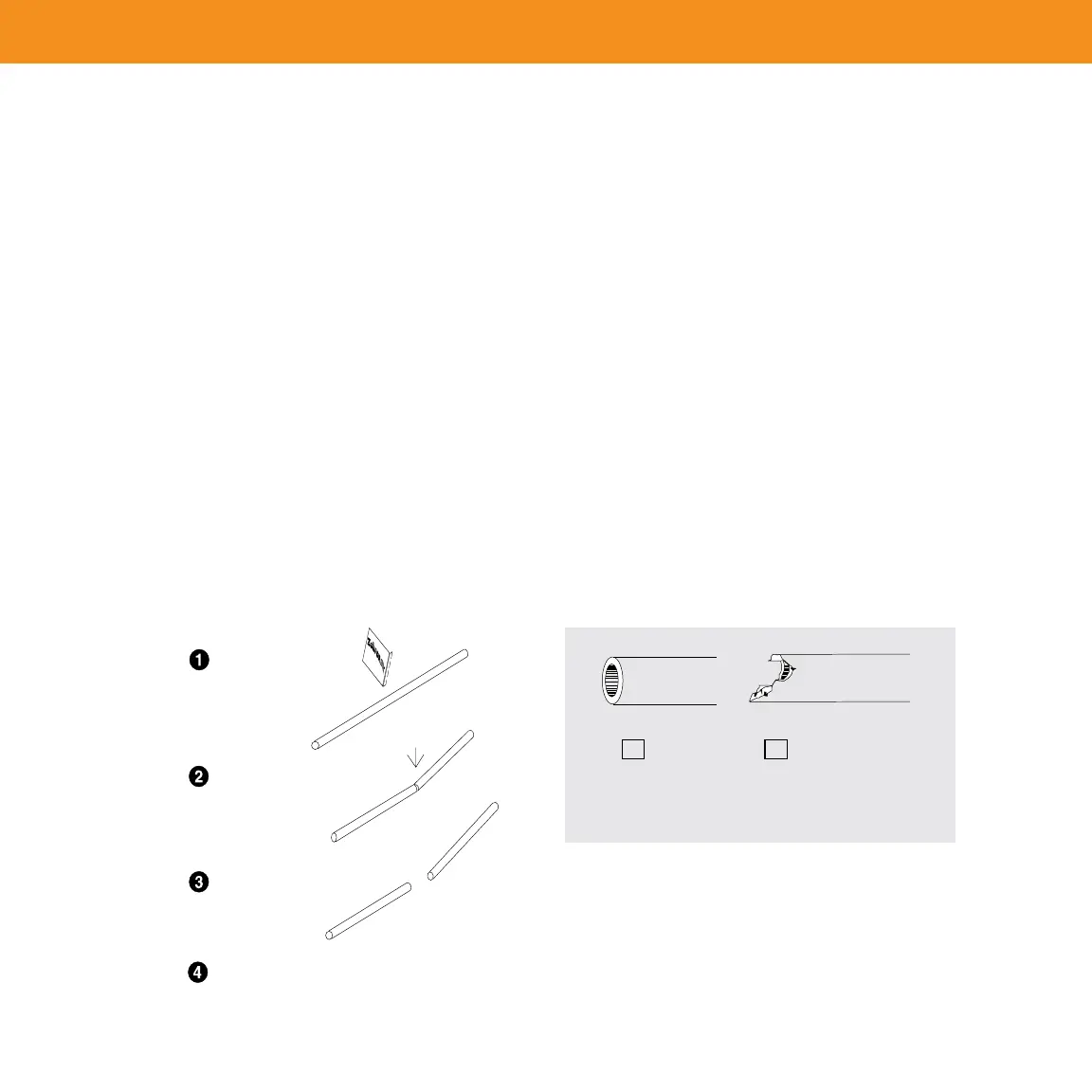

Place a capillary nut and ferrule on the injector end of the GC column, 1.

allowing a section of column to protrude. Trim one to two centimeters

(cm) from the protruding end to remove ferrule contamination that may

have entered the column (Figure 1). Inspect the cut with a magnifier to

ensure that a smooth, clean, square-cut edge has been made – cut again

if necessary (Figure 2).

Carefully hang the column in the GC oven, being cautious not to scratch or 2.

damage the polyimide coating on the capillary tubing. Rotate the column

to avoid sharp bends of the capillary column and any contact of the

column with oven surfaces.

Insert the column into the injector exactly the correct distance specified 3.

in the instrument manual. Tighten the ferrule nut finger-tight then ½ turn

with a wrench. If the column can still be moved, tighten another ¼ turn

until the column is secure.

Adjust the carrier gas.4.

Detector Installation

Note: For users with sensitive detectors such as MS and ECD, column

conditioning steps should be performed before installing the column to prevent

contamination and frequent maintenance of the detector.

Place the column nut and ferrule past the end of the column and cut a 1.

centimeter or two off the end of the column (Figure 1). Be sure that the

ferrule is the right size and pointing in the correct direction. Inspect the

cut with a magnifier and ensure that the cut is square and smooth (Figure

2). Cut again if needed.

Insert the outlet end of the column into the detector exactly the distance 2.

prescribed in the instrument manual. Distances will vary between

detectors. Tighten the ferrule nut finger-tight then ½ turn with a wrench.

If the column can still be moved, tighten another ¼ turn until the column

is secure.

Inspect the column connections for leaks using an electronic leak 3.

detector. Leaks at the inlet end may introduce oxygen to the column that

will result in increased column bleed and damage to the column phase.

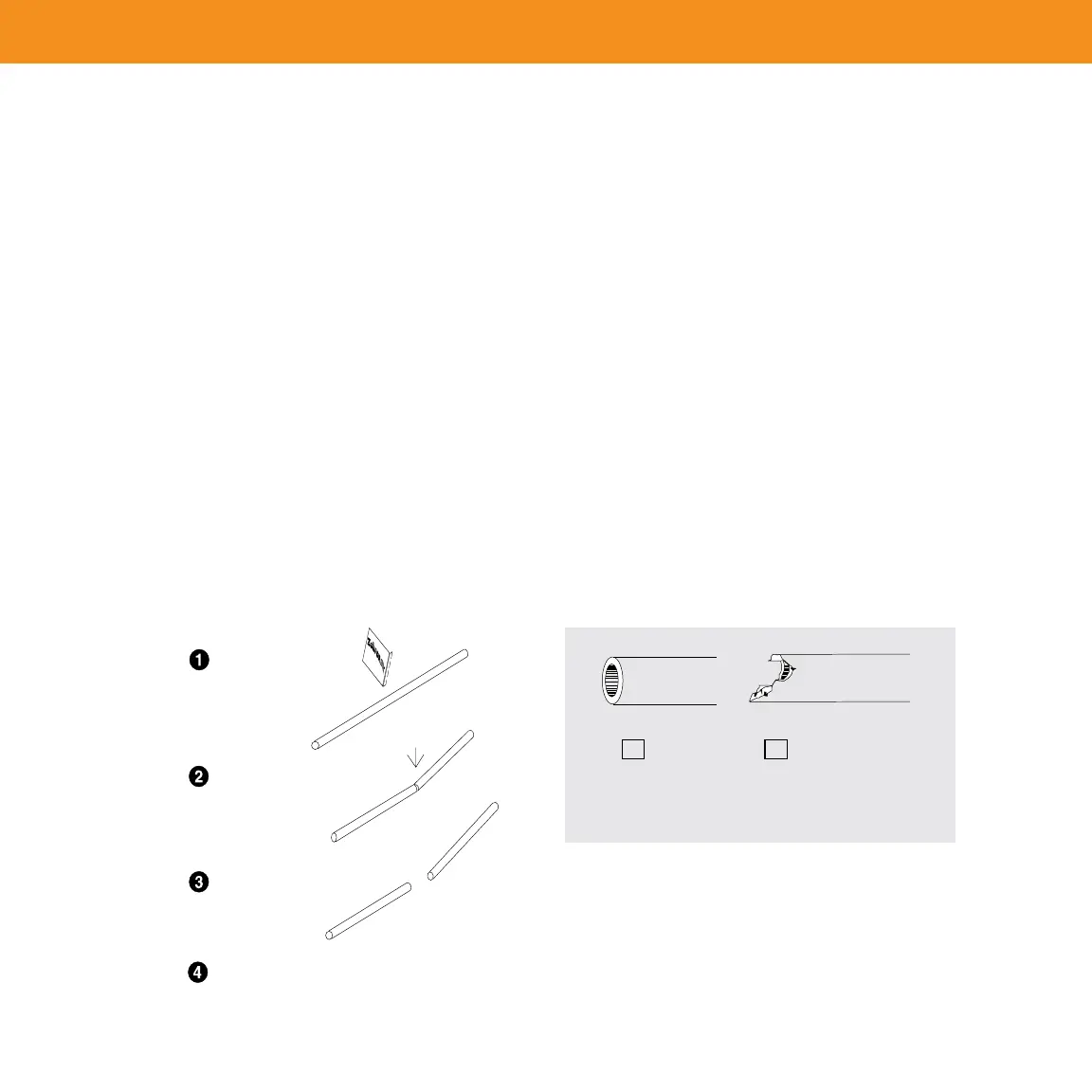

Figure 1: Cutting Fused Silica Tubing Figure 2: Proper and Improper Cut Capillary End

score capillary with

smooth edge of

wafer at a 45° angle

apply force in a

downward direction

tubing should break

cleanly

inspect cut with a

magnifying glass

b

a

Examples of: (a) A Properly Cut Fused Silica Column End

(b) An Improperly Cut End

Correct Incorrect

4

X

GC Column Installation

Loading...

Loading...