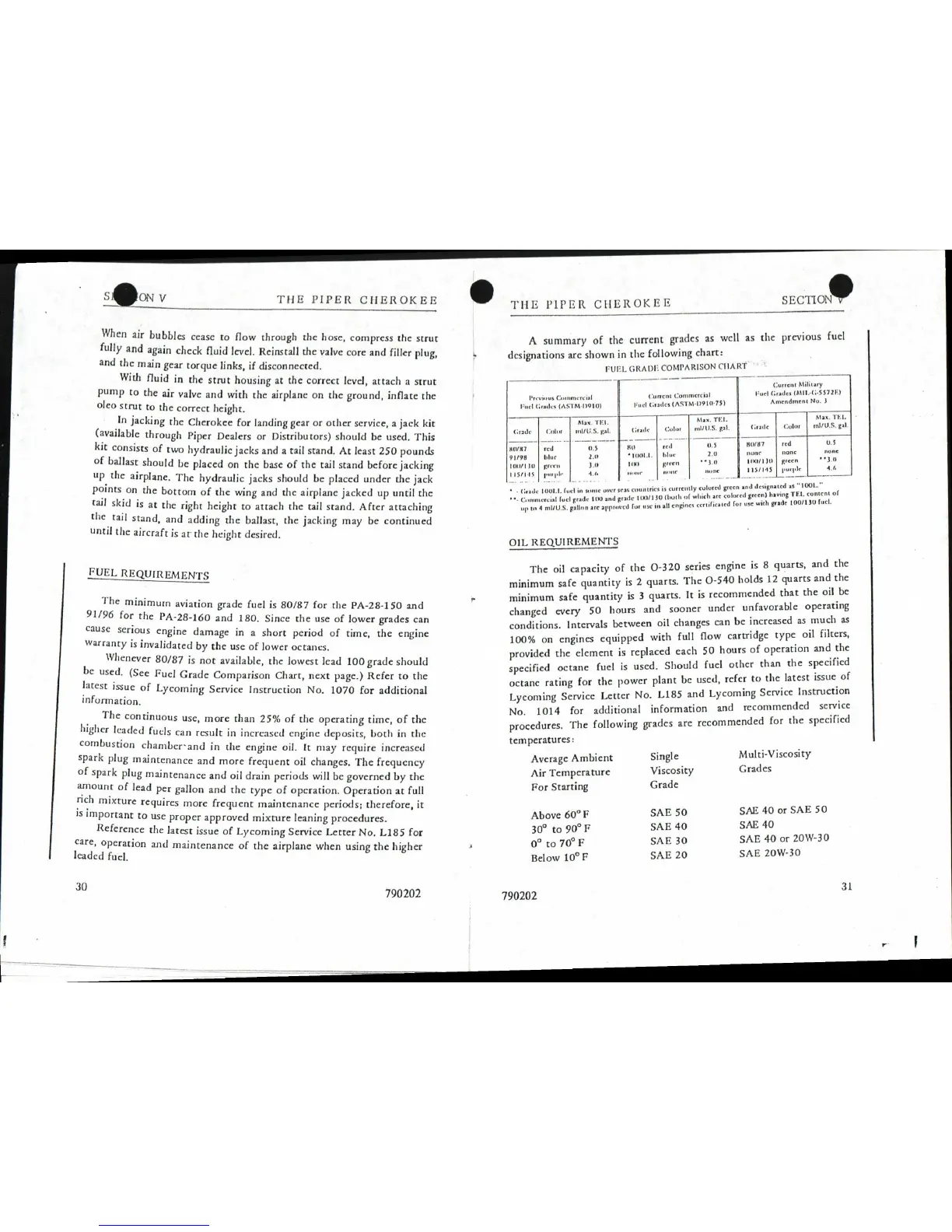

A summary of the current grades as well as the previous fuel

designations are shown in the following chart:

FUEL GRADE COMPARISON CHART

Previous Con inertial

Kid Grades (AS UM-1)910)

Current Commercial

Fuel Grades (AS1'1114)910.75)

Current Military

Fuel Grades (MI ...G•5572E)

Amendment No. 3

Atax. TE1.

Mae.

TEL

Max. TEL

Grade

Color

in1/13.S. gal.

Grade

Cohn

in1/11.S. gal.

Grade

Color

m1/11.S. gal.

80/117

red

0.5

80

red

0.5

80/87

red

0.5

none

91/98

blue

2.0

•

1001.1

bloc

2.0

none

none

"3.0

1011/130

green

3.11

100

green

"3.0

1)81/1311

green

4./'

115/145

purple.

4.6

1111111.

n

oo

n

none

115/145

purple

•

Grad, 1001.1.

fuel in some over cas countrie is currently colored green

and

designated as "1001..

•

•- Commercial fuel grade 100 and grade 1181/I 0 (both of which arc colored green) having TEL content of

up to 4 ni1/0.S. gallon arc approved for use i tall engines certificated for use with grade 100/130 fuel.

OIL REQUIREMENTS

The oil capacity of the 0-320 series engine is 8 quarts, and the

minimum safe quantity is 2 quarts. The 0-540 holds 12 quarts and the

minimum safe quantity is 3 quarts. It is recommended that the oil be

changed every 50 hours and sooner under unfavorable operating

conditions. Intervals between oil changes can be increased as much as

100% on engines equipped with full flow cartridge type oil filters,

provided the element is replaced each 50 hours of operation and the

specified octane fuel is used. Should fuel other than the specified

octane rating for the power plant be used, refer to the latest issue of

Lycoming Service Letter No. L185 and Lycoming Service Instruction

No. 1014 for additional information and recommended service

procedures. The following grades are recommended for the specified

temperatures:

THE PIPER CHEROKEE

SECTION.

Average Ambient

Single

Air Temperature

Viscosity

For Starting

Grade

Above 60

°

F

SAE 50

30

°

to 90

°

F

SAE 40

0

°

to 70

°

F

SAE 30

Below 10

°

F

SAE 20

Multi-Viscosity

Grades

SAE 40 or SAE 50

SAE 40

SAE 40 or 20W-30

SAE 20W-30

S•ON V

THE PIPER CHEROKEE

When air bubbles cease to flow through the hose, compress the strut

fully and again check fluid level. Reinstall the valve core and filler plug,

and the main gear torque links, if disconnected.

With fluid in the strut housing at the correct level, attach a strut

pump to the air valve and with the airplane on the ground, inflate the

oleo strut to the correct height.

In jacking the Cherokee for landing gear or other service, a jack kit

(available through Piper Dealers or Distributors) should be used. This

kit consists of two hydraulic jacks and a tail stand. At least 250 pounds

of ballast should be placed on the base of the tail stand before jacking

up the airplane. The hydraulic jacks should be placed under the jack

points on the bottom of the wing and the airplane jacked up until the

tail skid is at the right height to attach the tail stand. After attaching

the tail stand, and adding the ballast, the jacking may be continued

until the aircraft is at' the height desired.

FUEL REQUIREMENTS

The minimum aviation grade fuel is 80/87 for the PA-28-150 and

91/96 for the PA-28-160 and 180. Since the use of lower grades can

cause serious engine damage in a short period of time, the engine

warranty is invalidated by the use of lower octanes.

Whenever 80/87 is not available, the lowest lead 100 grade should

be used. (See Fuel Grade Comparison Chart, next page.) Refer to the

latest issue of Lycoming Service Instruction No. 1070 for additional

information.

The continuous use, more than 25% of the operating time, of the

higher leaded fuels can result in increased engine deposits, both in the

combustion chambcrand in the engine oil. It may require increased

spark plug maintenance and more frequent oil changes. The frequency

of spark plug maintenance and oil drain periods will be governed by the

amount of lead per gallon and the type of operation. Operation at full

rich mixture requires more frequent maintenance periods; therefore, it

is important to use proper approved mixture leaning procedures.

Reference the latest issue of Lycoming Service Letter No. L185 for

care, operation and maintenance of the airplane when using the higher

leaded fuel.

30

790202

790202

31

Loading...

Loading...