Background

In this third sketch, you will spin a servo motor back and forth between two

different positions at a set speed. The motor will operate at 25% speed. This

behavior will continue until the Stop/Reset button is pressed.

Servo motors allow for a lot more precision in movement than DC motors do.

Execute the Code

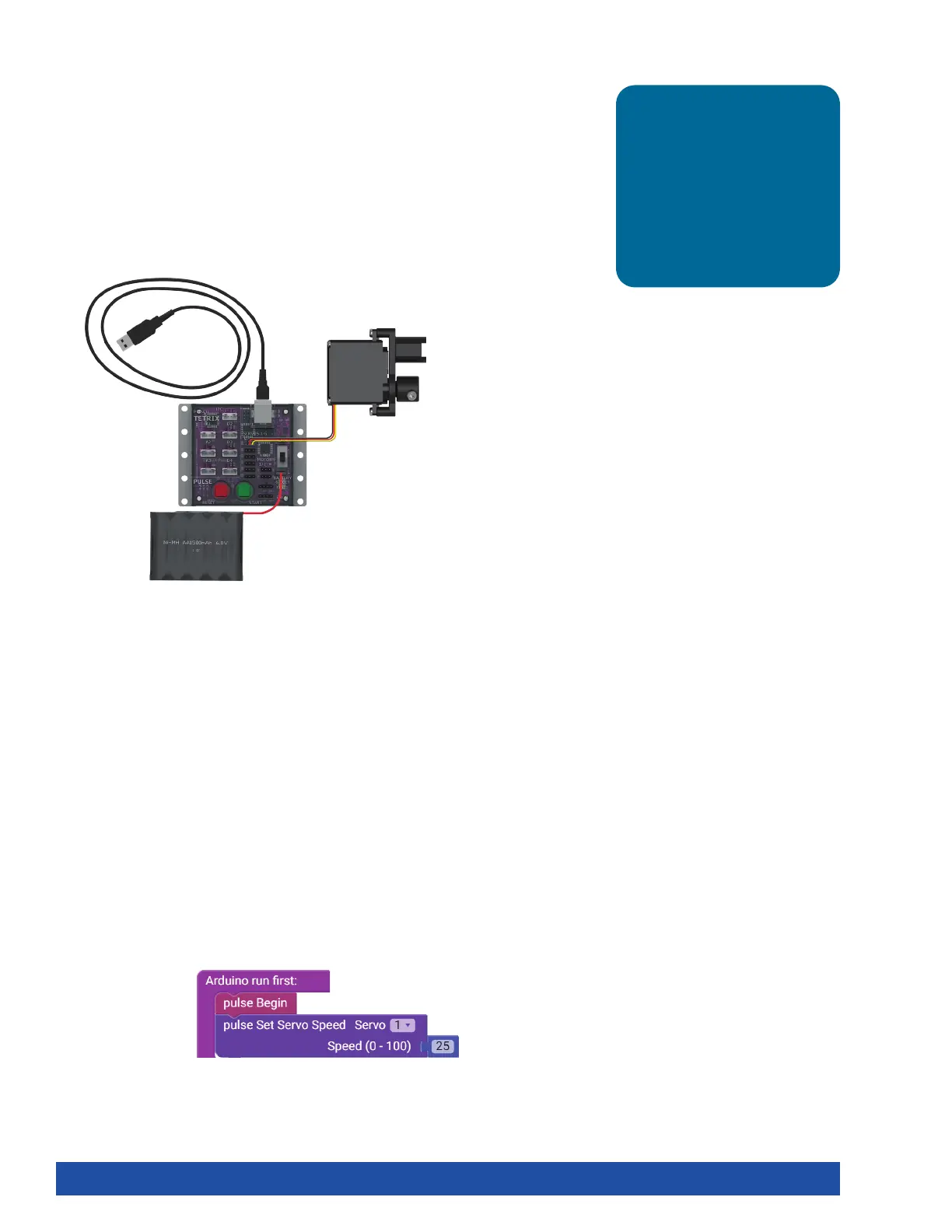

Before you can upload the sketch to the PULSE, remember to check your

connections. Keep in mind that you added a new connection with the motor. Plug

the end of the wire that extends from a servo motor into the Servo 1 port.

Upload the sketch. The green LED will light up, indicating that the code is ready

to execute. When this has happened, press the green Start button on the PULSE

controller.

Observe the direction and duration of the servo motor rotation. Did the motor’s

behavior match the intended program? Press the Stop/Reset button when you are

ready to stop the motor.

Further Investigate

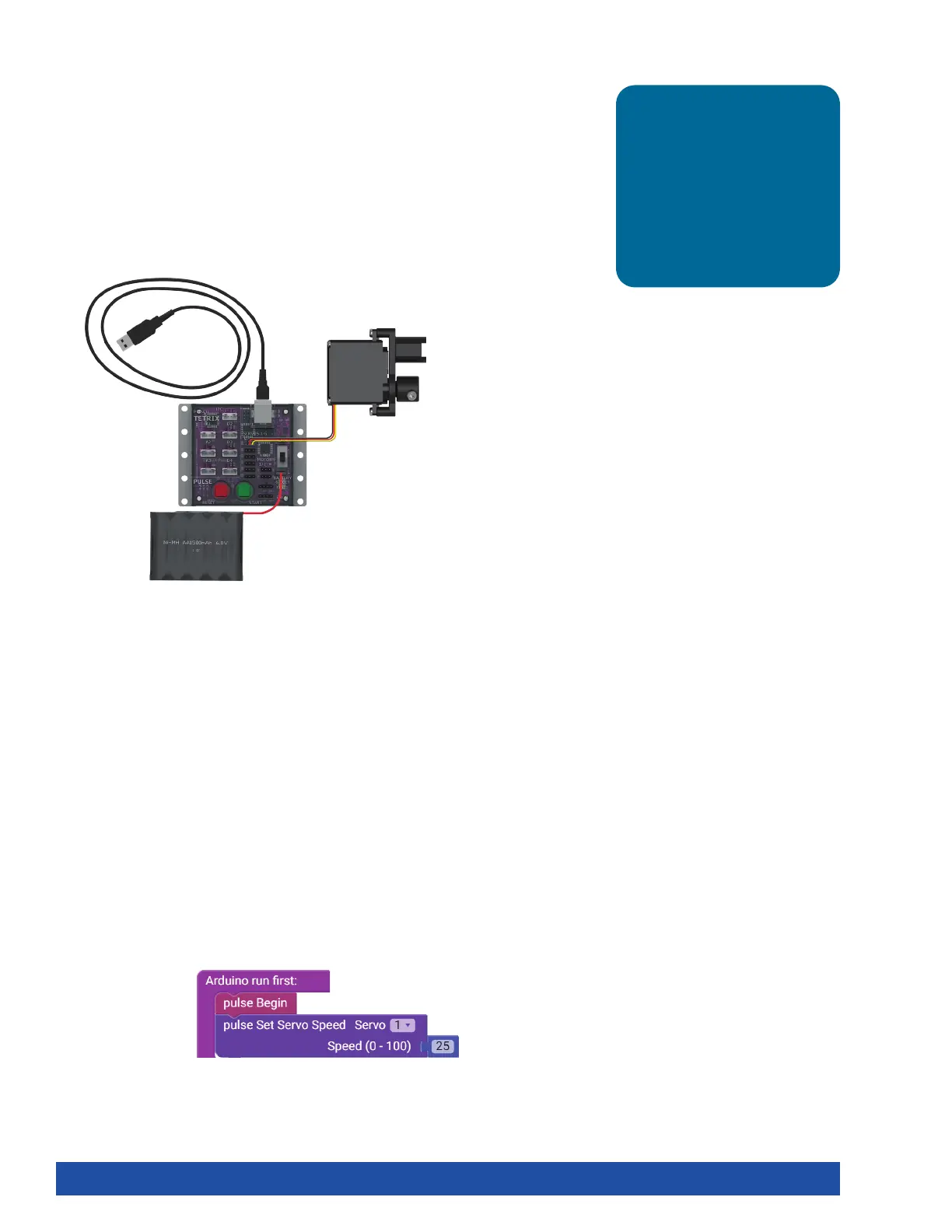

In this sketch, you will use two new PULSE blocks: pulse Set Servo Speed and pulse

Set Servo Position. Both blocks have two parameters, but they are different.

The two parameters of the pulse Set Servo Speed block are servo channel and servo

speed.

In the example, Servo 1 will spin at 25% power while it rotates to the position

commanded by the pulse Set Servo Position block. This block is in the setup portion

of the setup-loop block because it needs to be listed once at the beginning of the

program (Figure 35).

Tip: What’s the difference

between a DC motor and a

servo motor? A DC motor

has two wires and can rotate

continuously. A TETRIX servo

motor has three wires and

can be placed into different

positions but can’t rotate

beyond 180 degrees.

Figure 35

34 Getting Started Activities

Loading...

Loading...