Operating instructions SG 160 9 Fusion data

47

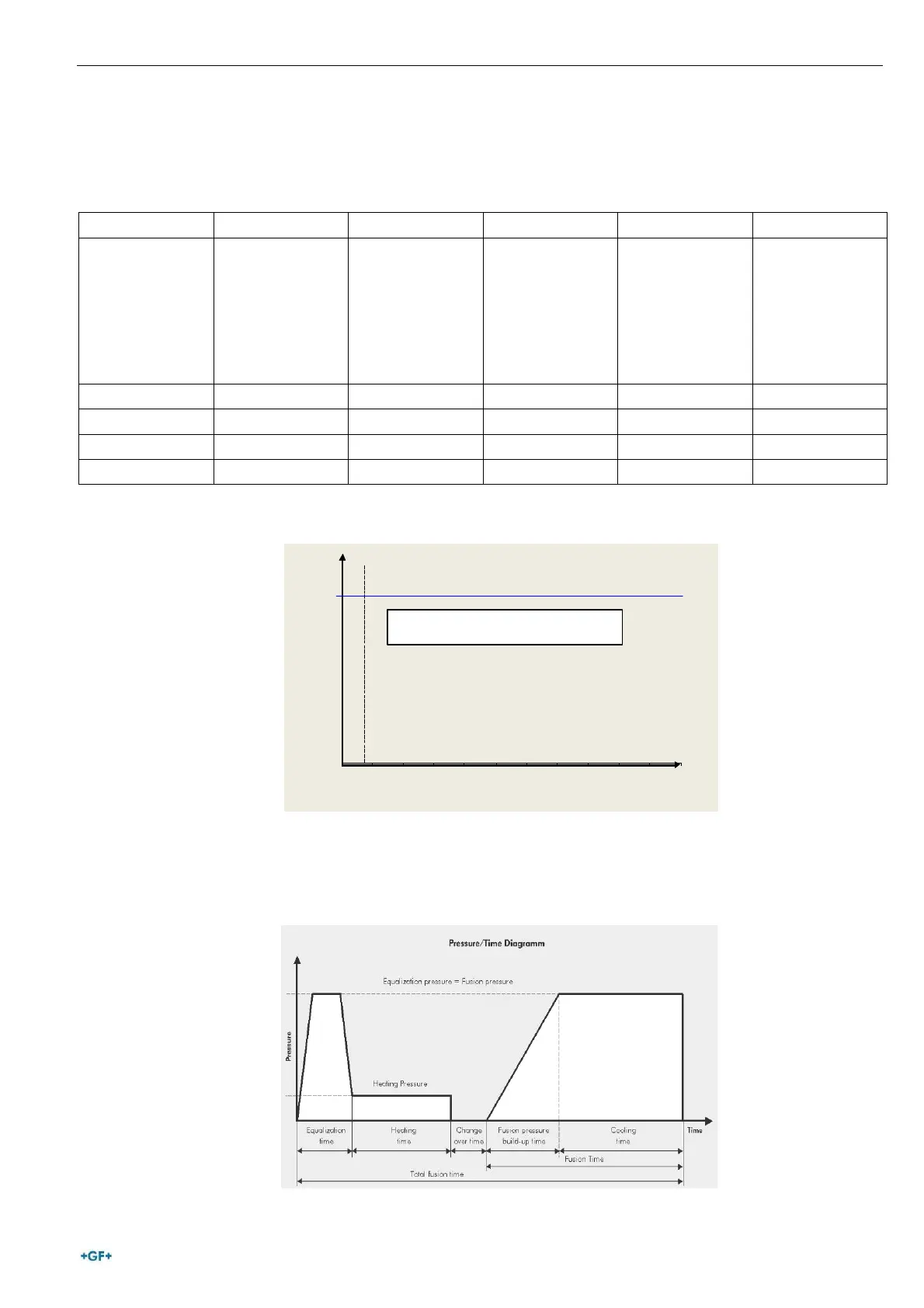

Heating element butt fusion of PVDF

Fusion chart according to DVS 2207-15

Heating element temperature 240 °C ± 8 °C

thickness

Bead height on the

heating element after

equalization time

(equalization at

0.10 N/mm

2

)

Heat soak time = 10 x

wall thickness +40 s

(heat soak

≈ 0.01 N/mm²)

Fusion pressure build-

up time

Cooling time at fusion

pressure

(p = 0.10 N/mm²

± 0.01)

Cooling time = 1.2 x

wall thickness + 2 min

(min.value)

(max. time)

(min.value)

1.9 – 3.5 0.5 59 – 75 3 3 – 4 5.0 – 6

3.5 – 5.5 0.5 75 – 95 3 4 – 5 6.0 – 8.5

5.5 – 10.0 0.5 – 1.0 95 – 140 4 5 – 7 8.5 – 14

10.0 – 15.0 1.0 – 1.3 140 – 190 4 7 – 9 14.0 – 19

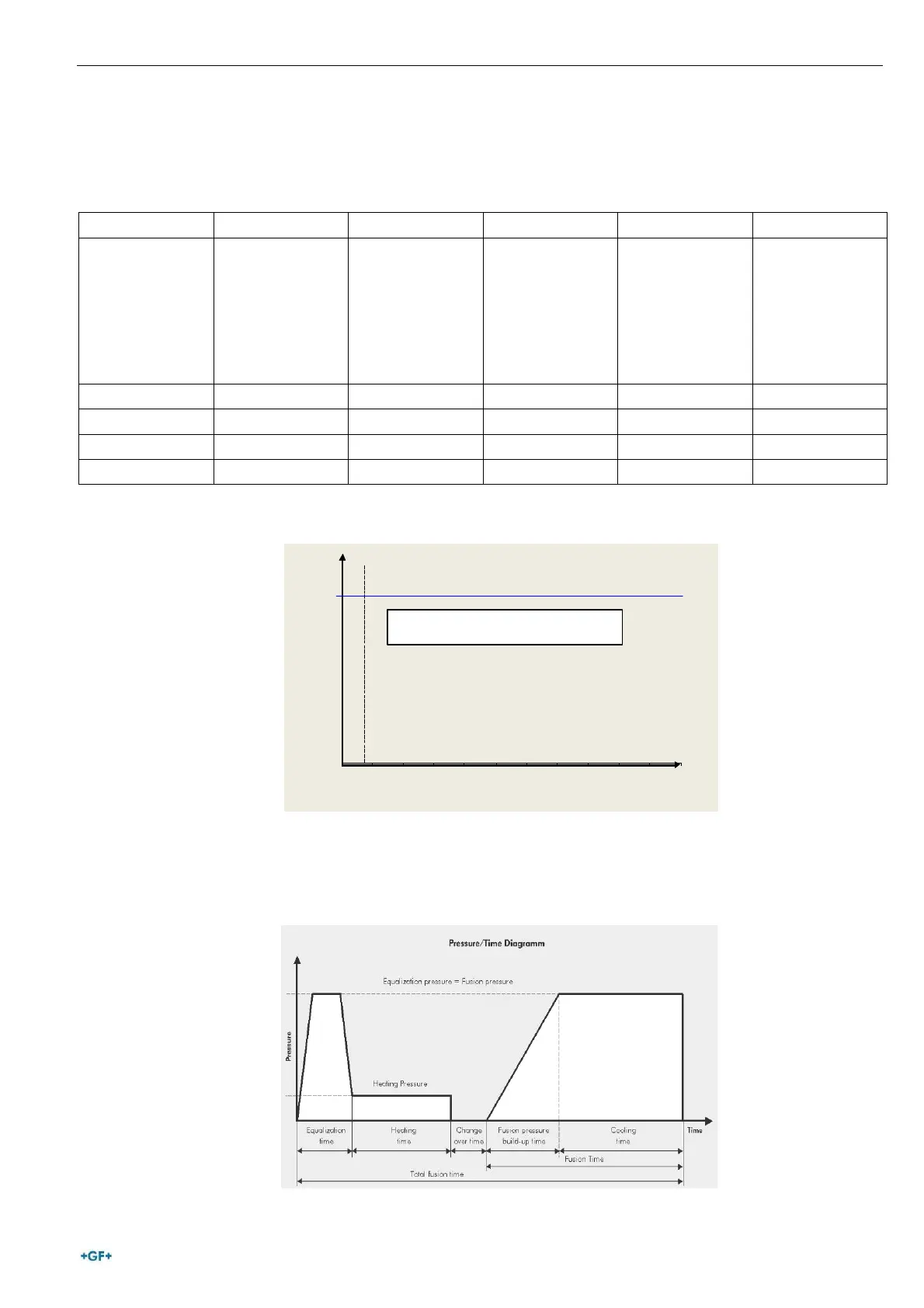

Diagram of standard values for heater temperatures in relation on pipe wall

thickness

Process steps for heating element butt fusion

215

220

235

240

Pipe wal l thickness / Rohrwanddicke /Spessore tu bo mm

°C

Loading...

Loading...