9.41

Chassis

9

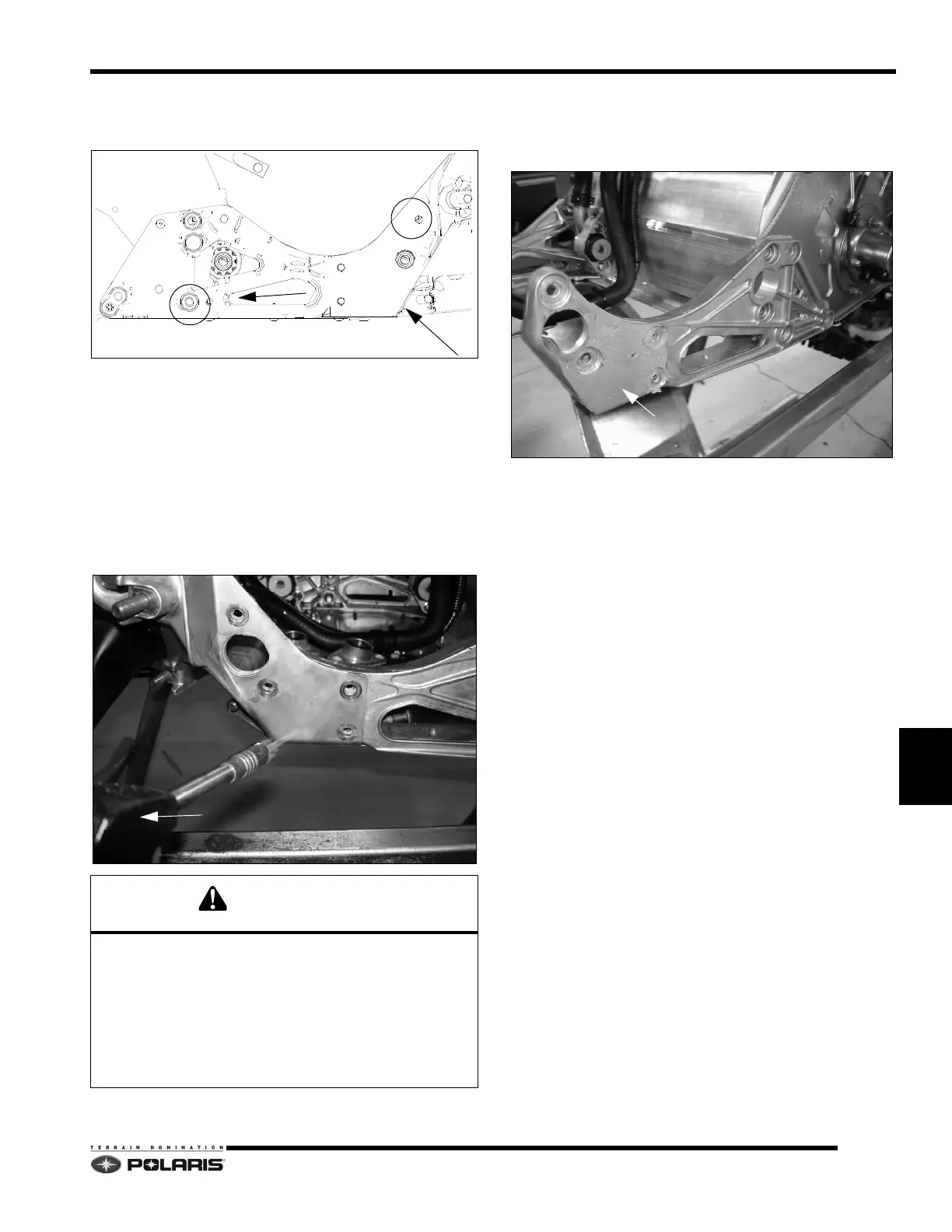

5. Remove the four remaining brace screws and nuts.

Note the screw located on the inside of the brace

attaching the brace to the bulkhead cooler.

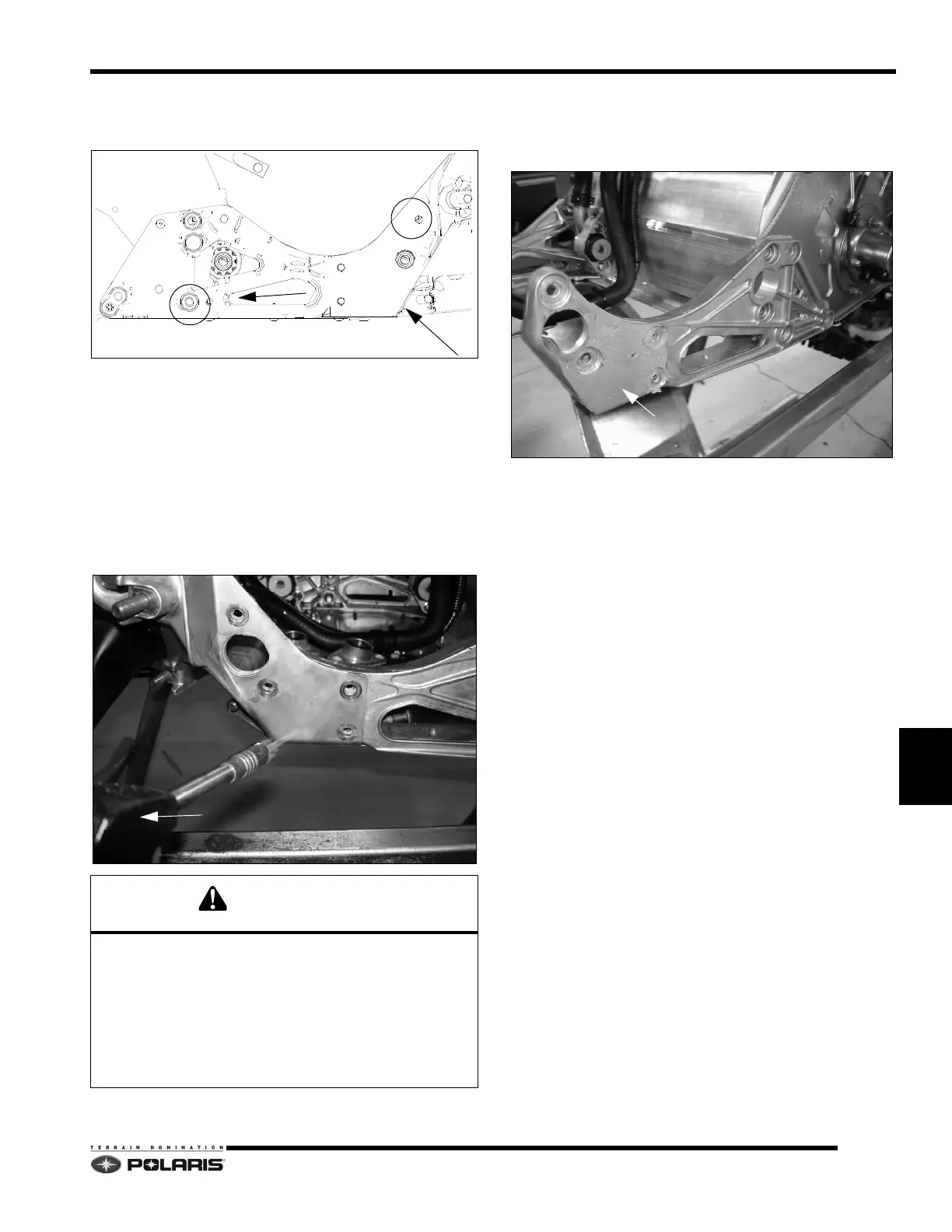

6. When all of the noted fasteners, nuts, and screws are

r

emoved, the next step is to heat where the brace

mounts to the tunnel and bulkhead clip.

7. Wearing heat resistant gloves, use a propane gas

to

rch to heat the where the brace mounts to the tunnel

and bulkhead clip.

Apply torch until adhesive begins to crackle. During

th

is time, the adhesive may smoke and bubble.

Continue heating the area

until the brace can be

separated from the bulkhead and tunnel.

NOTE: Left side shown.

8. Note the residual adhesive on the brace, bulkhead clip

an

d tunnel. If the component is to be re-used, the

adhesive must be completely removed. See Bonded

Component Surface Preparation section.

Keep flame away from flammable materials. Use torch

in well-ventilated area.

Only apply heat to area that requires adhesive bond

separation. Do not apply heat to areas of adhesive

where bond line separation is not needed. Doing so will

require removing the part, removing adhesive, and then

re-applying new adhesive.

Loading...

Loading...