Engine – Cayenne V8

Page 1.19

The lower part of the crankcase is machined and paired together with

the upper part. To keep the weight as low as possible, the spheroidal

graphite iron inserts are no longer used and the wall thickness has been

reduced.

A low-pressure chill-casting procedure is used to make the upper and

lower part of the crankcase.

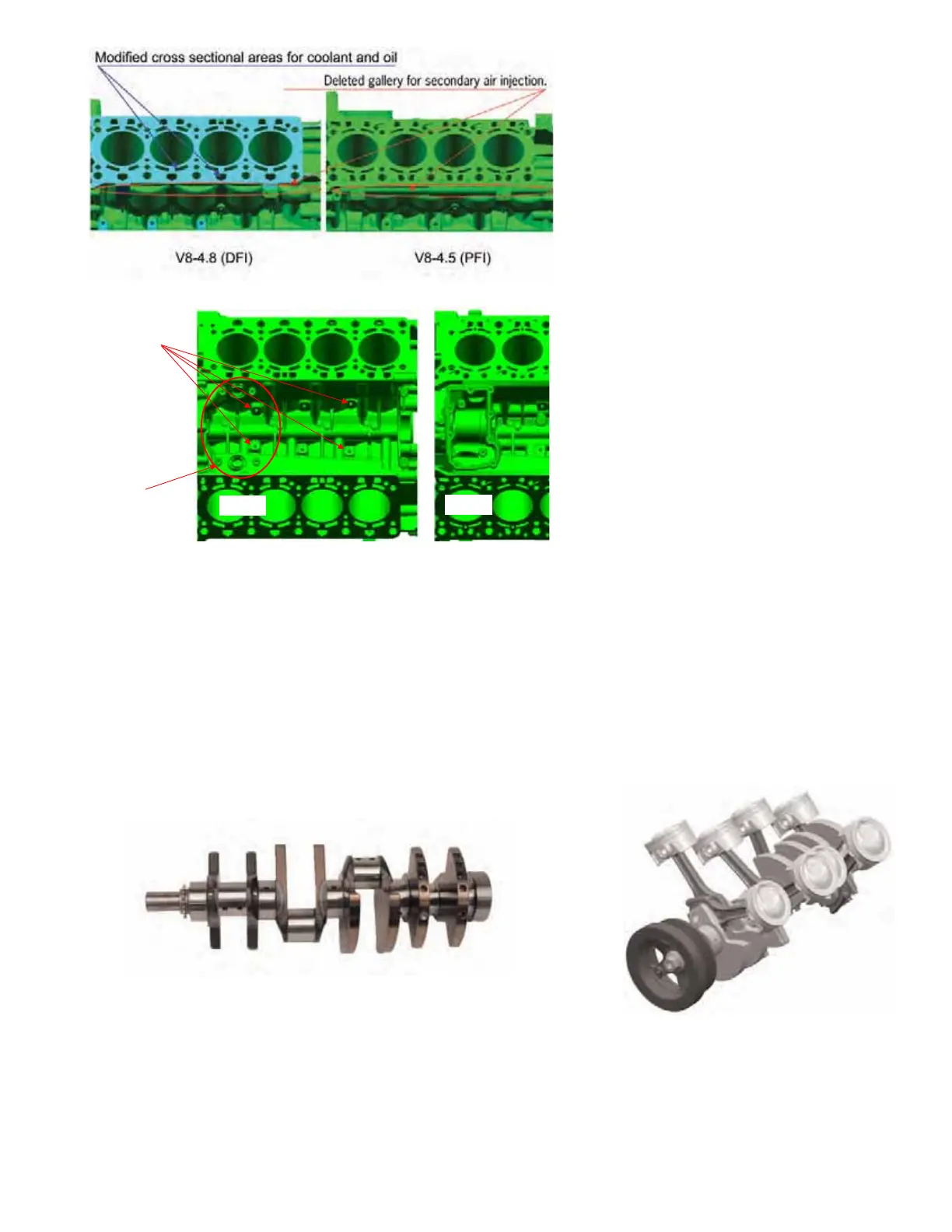

Crankshaft

The drop-forged crankshaft runs in five bearings and has eight counter-

weights. Main bearing 3 is designed as a thrust bearing. Axial play is

determined by two thrust washers, which are inserted into the bearing

halves. The main bearings are two-component bearings and have a

diameter of 64 mm. Since the lower part of the crankcase is made of

an all aluminum alloy, the main bearings are stronger than those used

previously and the retaining lugs have been changed to avoid confusion.

The main bearings are also “lead-free.”

4 knock sensors

Removed

thermostat

housing

V8-4.8

V8-4.5

Loading...

Loading...