Do you have a question about the Porter-Cable OMNIJIG 7116 and is the answer not in the manual?

Essential safety rules for operating power tools to prevent injury.

Rules for safe handling, setup, and material use during operation.

Detailed instructions on how to operate the router to make dovetail cuts.

How to inspect the routed joints and adjust depth for a snug fit.

Steps to set up the jig and templet for cutting the female dovetail.

Instructions for routing the female dovetail tails and managing fork spacing.

Instructions for preparing and cutting the male dovetail pins.

How to inspect and adjust the fit between male and female dovetail boards.

Steps for marking, setting up, and carefully routing box joints.

Instructions for safely cutting male dovetails using the templet.

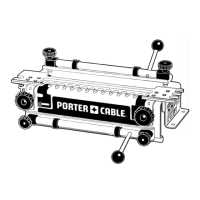

The Porter-Cable OMNIJIG® is a professional power tool designed for creating various types of woodworking joints, primarily dovetails and box joints. It is used in conjunction with a Porter-Cable router, templet guides, and router bits to produce precise and strong corner joints for drawers and boxes, as well as sliding joints for shelves.

The OMNIJIG® facilitates the routing of different joint types by providing a stable clamping system for workpieces and a templet guide for the router. The user secures the wood pieces in the jig, positions the appropriate templet, and then guides a router with a specific bit along the templet's contours to cut the desired joint. This process ensures consistent and accurate cuts, making it suitable for both hobbyists and professional woodworkers.

The OMNIJIG® comes in two main models:

Accessory Templets and Bits: The manual lists several accessory templets and corresponding router bits for different joint types:

1/2" Half-Blind Dovetails:

1/4" Half-Blind Dovetails:

1/2" Hand Dovetails (2" Spacing):

Adjustable Through Dovetails:

1/2" Box Joints:

Tapered Sliding Dovetails:

The OMNIJIG® base includes two clearance holes for 3/8" dia. bolts for secure mounting to a workbench or stand.

The OMNIJIG® is designed for versatility and precision in woodworking joinery. Key usage features include:

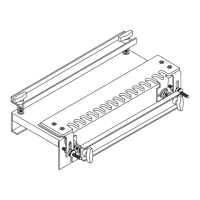

Secure Clamping System: The jig features front and top clamps (items 2 and 3 in Fig. 2) with clamp nuts (item 11) and clamping levers & knobs (item 13) to securely hold workpieces. The clamp nuts can be adjusted to maintain uniform clamping pressure.

Adjustable Templet Location: The front-to-back positioning of the templets (item 4) is adjustable using spacers (item 14) and rod nuts (item 15), allowing for fine-tuning of the templet position for different joint requirements.

Stop Bars: The jig incorporates top and front stop bars (items 6, 7, 8, 9) with locking screws (item 10) to accurately position workpieces for routing.

Router Setup: The manual provides detailed instructions for setting up the router, including inserting the correct templet guide and dovetail bit, and adjusting the bit projection for specific joint types (e.g., 19/32" for 1/2" half-blind dovetails, 5/8" for 1/4" half-blind dovetails).

Joint Types: The OMNIJIG® supports a wide range of joint types:

Safety Precautions: The manual emphasizes several safety rules, including securing the work, keeping hands clear of cutters, maintaining a firm grip on the router, ensuring the motor has stopped before adjustments, and using safety glasses and ear protection. It also warns about toxic preservatives in some wood and the importance of reading all instructions.

The OMNIJIG® requires minimal but consistent maintenance to ensure longevity and proper function:

The OMNIJIG® is a robust and versatile tool designed to simplify complex woodworking joinery, offering precision and repeatability for a variety of projects.

| Type | Dovetail Jig |

|---|---|

| Dovetail Type | Through, Half-Blind |

| Maximum Joint Width | 12 inches |

| Compatibility | Router |

| Material | Aluminum, Steel |

Loading...

Loading...