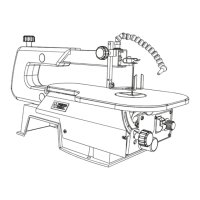

18

Blade guides

1. Loosen two front hex socket screws (1)

with a hex wrench.

2. Move the guide pins (2) as close to the

sides of the blade (3) as possible without

pinching it.

3. Using the feeler gauge, measure the

spaces between the guide pins and the

blade. Adjust to 0.002 in. (0.05 mm).

4. Tighten two front hex socket screws (1).

Fig. L

5. Loosen two lock screws (4), move the

lower blade guide bracket (5) in or out

until the guide pins (2-Fig. K) are just

behind the saw teeth. Tighten two lock

screws (4).

Fig. M

Support bearing

6. Loosen the support bearing hex screw (6)

on the right side of the band saw with the

hex wrench.

7. Move the support bearing shaft (7) in or

out until the support bearing (8) is 1/64 in.

(0.4 mm) behind the saw blade.

1

2

3

2

1

4

5

8. Tighten the support bearing hex

screw (6).

9. The back edge of the blade (3) should be

positioned 1/16 in. (1.6 mm) to 1/8 in.

(3.2 mm) from the surface of the support

bearing (8).

Fig. N

DRIVE BELT TENSION

1. Disconnect the machine from the power

source.

2. Loosen the hex screw (1) on the motor

with a 6 mm wrench.

3. Push the motor down to add tension to

belt. Move the motor up to loose tension

to belt.

4. The belt is properly tensioned when

moderate nger pressure on the belt

between the two pulleys causes a 1/2 in.

deection.

5. Tighten the hex screw (1) that secures

motor.

Fig. O

6

7

8

1

tension

loose

Loading...

Loading...