Scroll Medical & Laboratory Compressed Air Systems

Powerex • 150 Producon Drive • Harrison, OH 45030 • USA

P 1.888.769.7979 • F 513.367.3125 • www.powerexinc.com

IN907800AV • 08/2018

Page 2 of 40

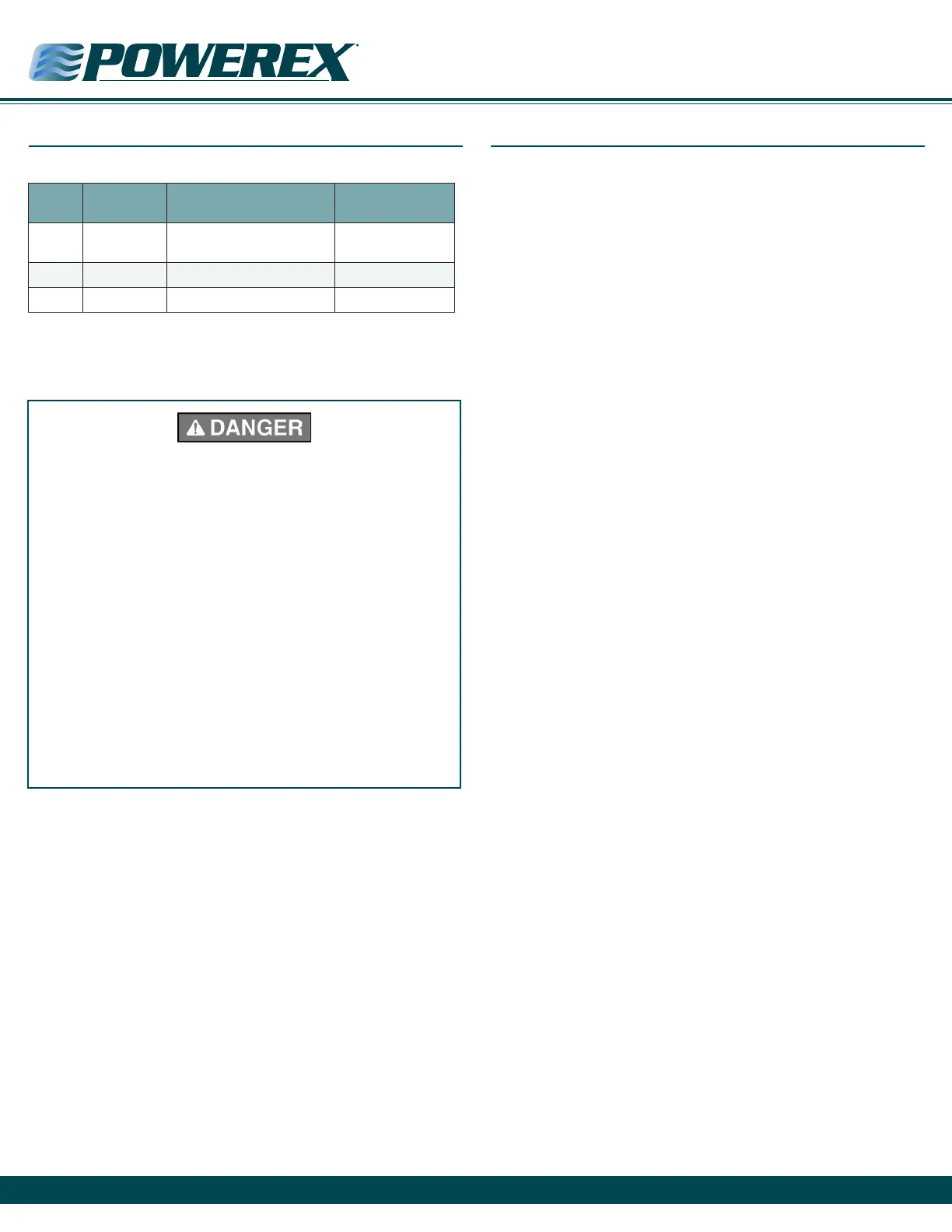

Specicaons (Connued)

HP Air End Discharge Pressure (PSIG)

Air Delivery

(SCFM)

3 SLAE03EB 95-115 (125-145 oponal) 8.8 @ 100 PSIG

7.5 @ 145 PSIG

5 SLAE05E 95-115 (125-145 oponal) 15.2 @ 100 PSIG

5 SLAE05EHP 95-115 (125-145 oponal) 12.5 @ 100 PSIG

NOTE: For system electrical informaon, see wiring diagram

shipped with unit.

Compressor Performance (per basemount)

Breathable Air Warning

This unit is NOT equipped and should NOT be used “as is”

to supply breathing quality air. For any applicaon of air for

human consumpon, you must t the air compressor/pump

with suitable inline safety and alarm equipment. This addional

equipment is necessary to properly lter and purify the air to

meet minimal specicaons for Grade D breathing as described

in Compressed Gas Associaon Commodity Specicaon for air,

OSHA, ANSI and/or Canadian Standards Associaons (CSA).

DISCLAIMER OF WARRANTIES

IN THE EVENT THE COMPRESSOR IS USED FOR THE PURPOSE

OF BREATHING AIR APPLICATION AND PROPER IN-LINE SAFETY

AND ALARM EQUIPMENT IS NOT SIMULTANEOUSLY USED,

EXISTING WARRANTIES ARE VOID, AND POWEREX DISCLAIMS

ANY LIABILITY WHATSOEVER FOR ANY LOSS, PERSONAL INJURY

OR DAMAGE.

For Laboratory Systems

Components

Powerex open scroll systems are designed to supply connuous oil-

free air by using the most advanced scroll technology.

The Powerex scroll compressor oers a dynamically balanced air

end which insures vibraon-free operaon. The rotary design permits

a connuous 100% duty cycle. No oil separaon, oil ltraon, or inlet

valves are required on the Powerex Scroll unit. Each compressor

shall be belt driven oil-less rotary scroll single stage, air-cooled

construcon with absolutely no oil needed for operaon. Direct drive

compressors shall not be used. The rotary design shall not require any

inlet or exhaust valves and shall be rated for 100% connuous duty.

Systems consist of mulple compressor pumps that are automacally

controlled and alternated to equalize usage and wear. Medical

systems have one or more pumps designated as the reserve and their

output is not ulized for normal system capacity rangs.

The Powerex oil-less rotary scroll air compressor is based on the

theory of scroll compression. A scroll is a free-standing, intricate

spiral bounded on one side by a solid, at plane or base. A scroll set,

the basic compression element of a scroll compressor, is made up

of two idencal spirals which form right and le hand parts. One of

these scroll components is indexed or phased 180° with respect to

the other so the scrolls can mesh. Crescent-shaped gas pockets are

formed and bounded by the spirals and the base plate of both scrolls.

As the moving scroll is orbited around the xed scroll, the pockets

formed by the meshed scrolls follow the spiral toward the center

and diminish in size. The moving scroll is prevented from rotang

during this process so that the 180° phase relaonship of the scrolls

is maintained. The compressor’s inlet is at the outer boundary of the

scrolls. The entering gas is trapped in two completely opposite gas

pockets and compressed as the pockets move toward the center. The

compressed gas is discharged through the outlet at the center of the

xed scroll so no valves are needed.

Compressor systems are ed with single point connecon intake

manifolds. For medical systems the manifold must be connected to

air intake piping located as specied in NFPA99. Lab systems may

ulize room air for the intake. Parcle ltraon is provided by the

intake lter assemblies in each branch of the compressor system.

When remote intake systems take in humid warm air from outdoors,

and route it through air-condioned buildings, water will condense in

the intake piping. NOTICE: Water will destroy the compressor pump

if it is ingested. The air lters will not stop water. Water trapping drip

legs must be designed, installed and maintained by the responsible

pares. The intake system is also equipped with isolaon valves

allowing the line to be closed if a branch is opened for service. The

ball valve handles have been removed and shipped separately to help

avoid accidental closure of the valves when the system is running.

NOTICE Running the pumps with the intake valve closed will damage

the pumps. Powerex recommends that the system be locked out if

the valve is closed.

Each compressor pump is ed with exible connecons on the

intake and exhaust side. The compressed air from each pump is

monitored by a temperature switch that will work with the controls

to shut down the system if the air temperature exceeds design limits.

Loading...

Loading...