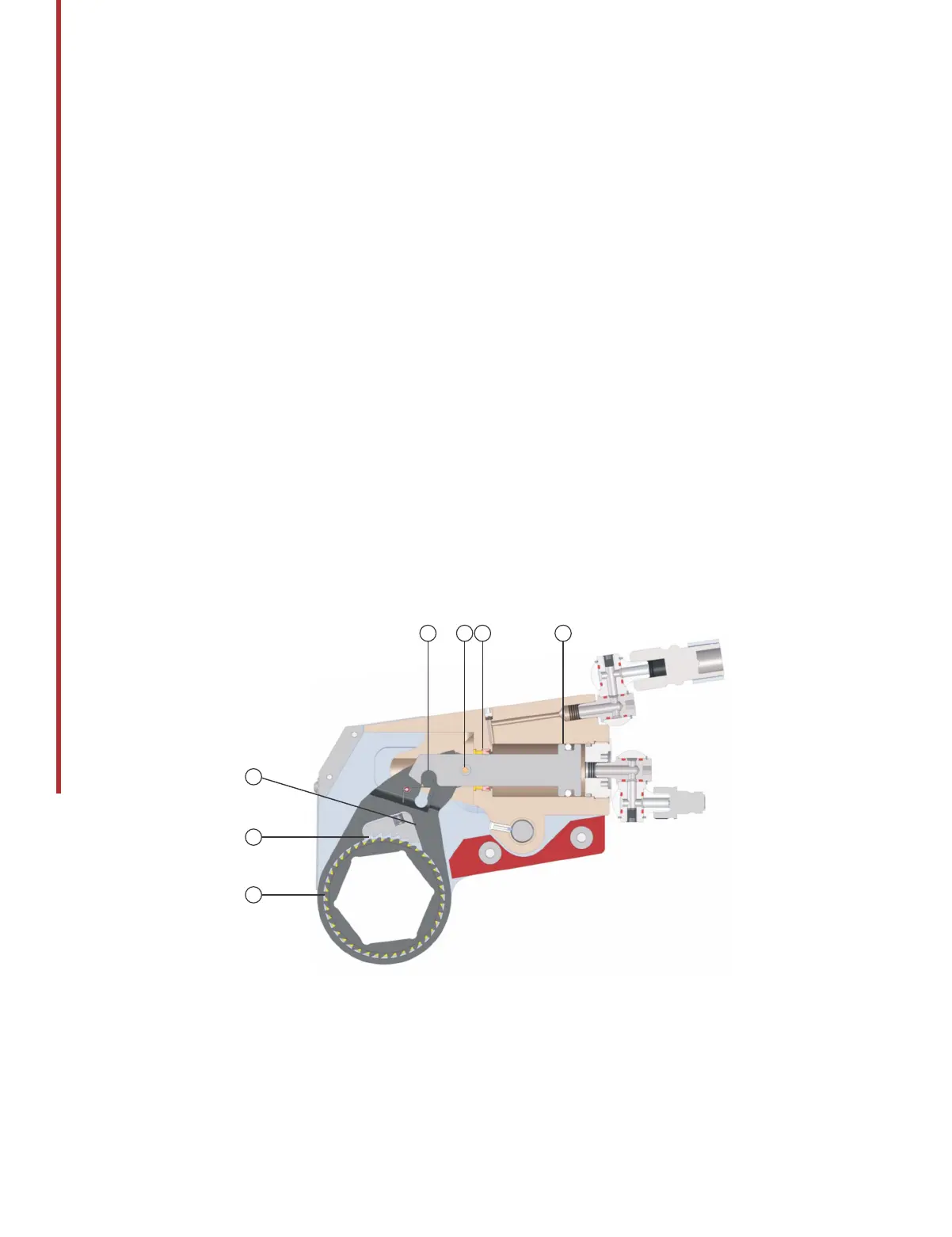

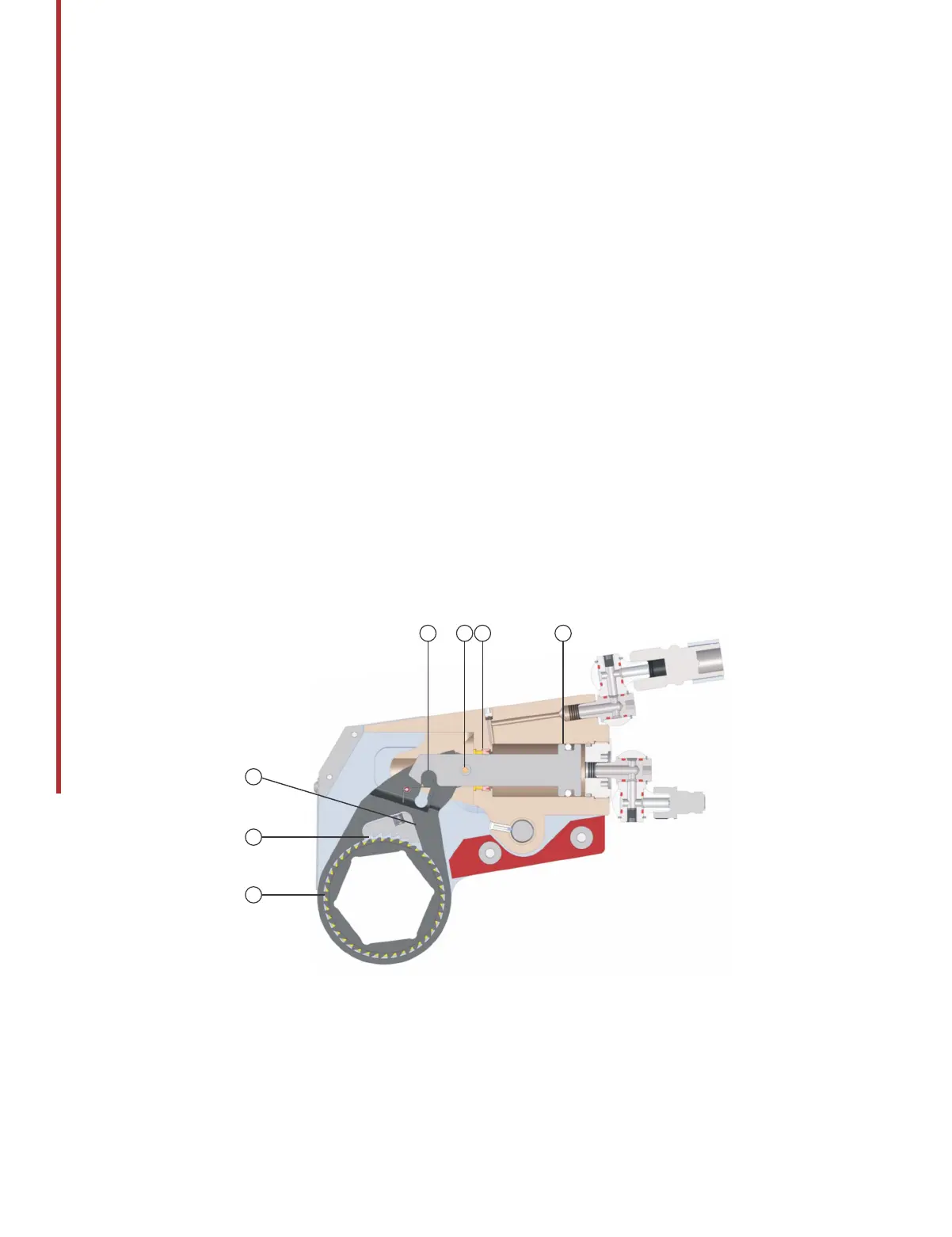

2.4 LUBRICATION :

The frequency for the lubrication is dependent on operating conditions The Hydraulic Torque Wrench used in a clean enclosed

environment will require less servicing than a tool used open atmosphere and dropped in loose dirt or sand. Synthetic Grease is used

for lubrication. Whenever lubrication is required, lubricate as follows:

1. By removing Link Pin separate the Low Profile Cylinder from the Ratchet Link if they are joined.

2. After wiping of the old grease, apply Synthetic Grease to the hook notch in the Piston rod and make a thin layer of Synthetic Grease

onto the sides and faces of the two Sliders.

3. Disassemble the Ratchet Link as instructed in the Section 3 of the Maintenance and wash the components in a suitable cleaning

solution in a well-ventilated area.

4. Dry the components, then apply a film of Synthetic Grease onto the wear surface of both Side Plate Sleeves and the hubs of the

Ratchet.

5. Apply a light film of Synthetic Grease onto the inner faces of both Side Plates covering the area where the Drive Plate and

Drive Segment Pawl travel. DO NOT over grease the teeth of the Drive Segment or Ratchet. It can prevent the teeth from

engaging properly.

6. Reassemble the Ratchet Link as instructed in the Maintenance Section.

Refer Figure 5

10

PXD Series Operation Manual

Figure 5 - Wrench Lubrication Point

4

3

2

1

5

7

6

Loading...

Loading...