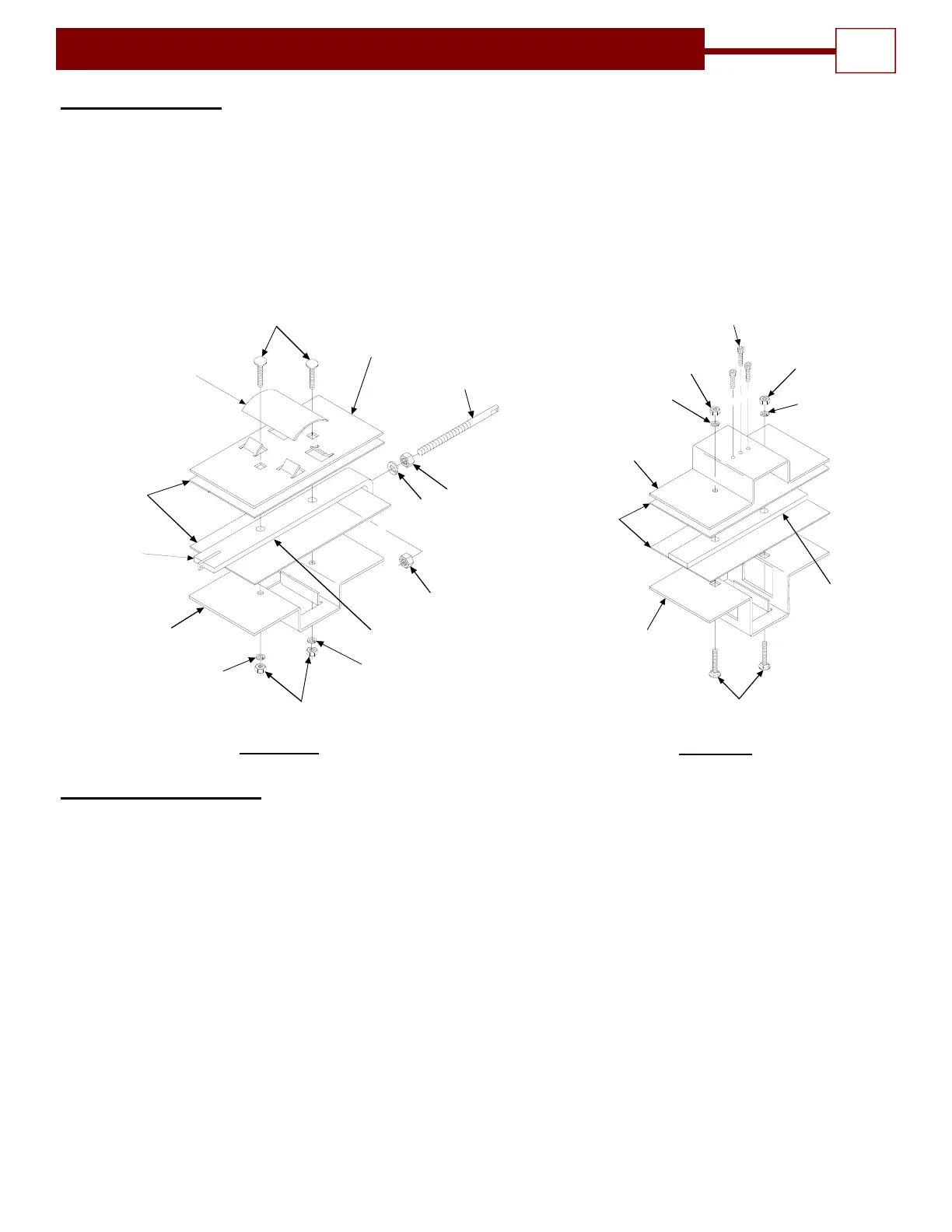

Slide Assembly

1. Assemble top plate, lower drive plate, center drive bar and two nylon inserts using two 5/16 x 1 ¼

carriage bolts, two 5/16 lock washers and two 5/16 hex nuts as shown in Figure # 3A.

2. Install 3/8 chain take-up bolt into slide assembly using one 3/8 lock washer and two 3/8 hex nuts

as shown in Figure # 3A. (DO NOT TIGHTEN NUTS)

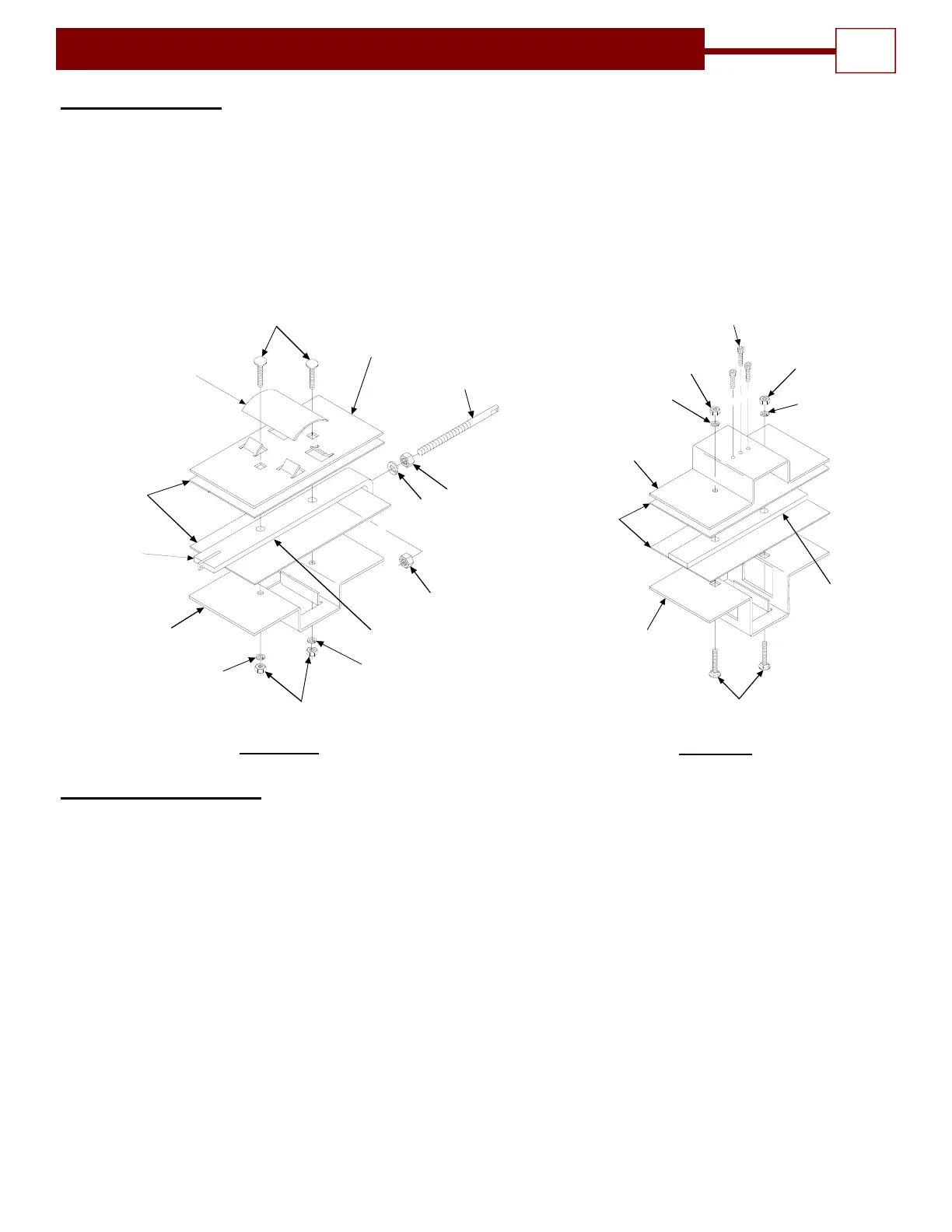

3. For Bi-Part Slide assembly see figure 3B.

INSTALLATION INSTRUCTIONS

7

5/16 X 1-1/4"

CARRIAGE

BOLTS

TOP PLATE

TAKE UP

BOLT

3/8" HEX NUT

3/8" LOCK

WASHER

3/8" HEX NUT

5/15" LOCK

WASHER

5/15" LOCK

WASHER

5/16" HEX NUTS

NYLON INSERTS

CENTER BAR

NYLON CHAIN

DEFLECTOR

CENTER

DRIVE BAR

LOWER

DRIVE PLATE

FIGURE 3A

3/8" LOCK WASHER

NYLON

INSERT

BI-PART TROLLEY

UPPER DRIVE

PLATE

#10 SOCKET HEAD

CAP SCREWS

(3)

3/8" HEX NUT

3/8" LOCK WASHER

3/8" HEX NUT

TROLLEY

CENTER

GUIDE

DEEP

ENGAGEMENT

LOWER DRIVE

PLATE

5/16 X 1-1/4" LG.

CARRIAGE BOLTS

FIGURE 3B

Operator Assembly

1. Install trolley slide assembly on track assembly with chain take-up bolt (7) pointing away from end

of track where power head (8) will be mounted as shown in Figure # 4. Note: If Bi-part

installation, slide Bi-Part trolley slide on first.

2. Mount power head to track assembly using four 3/8 x ¾ long hex head bolts, four 3/8 lock

washers and four 3/8 hex nuts, as shown in Figure # 4.

3. Turn operator assembly over and back off chain adjustment nut to the end of the threads on chain

take-up bolt (7). See Figure # 5.

4. Layout drive chain (9) next to operator assembly work surface.

5. Thread one end of the operator drive chain around operator drive sprocket and connect to the

drive tab on the trolley slide assembly with a chain connecting link (10). See figure 5A and figure

6.

6. Thread the other end of the drive chain (9)around the idler roller assembly (3).See Figure #6.

7. Pull drive chain (9) tight up to trolley slide assembly; mark link that lines with hole on chain take

up bolt on slide assembly and cut drive chain to length. Note: If installing a bi-part operator,

drive chain (9) must pass through Bi-Part slide assembly (15) before being connected to

chain take up bolt (7) on standard slide assembly (5). See figure 5B and figure 6.

Loading...

Loading...