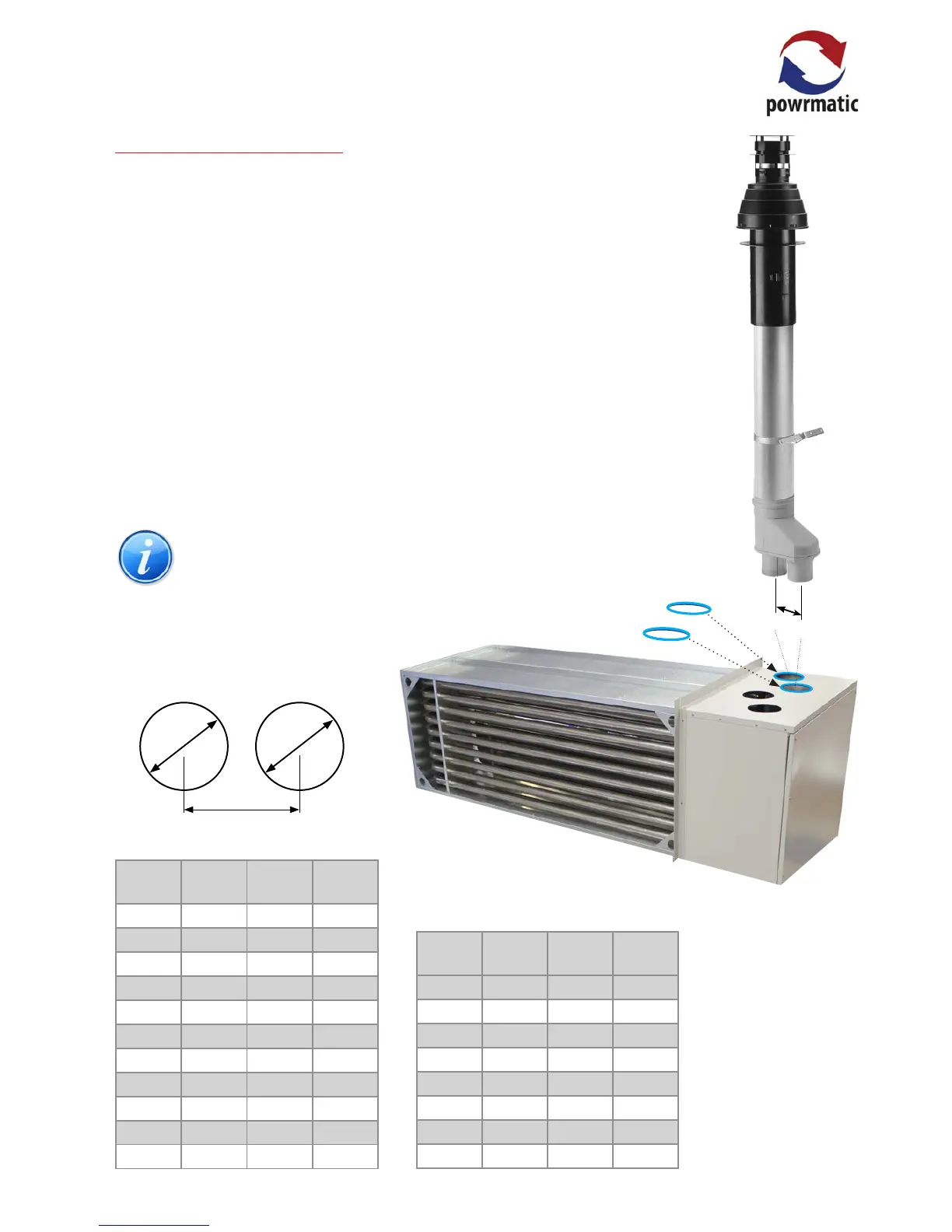

HEMNVx HEMSL A CRS ØD

10-3 n/a 120 91

15-4 n/a 120 91

18-5 n/a 120 91

25-5 n/a 142 112

30-6 30-6 142 112

40-8 n/a 142 112

n/a 45-9 142 112

50-6 50-6 142 112

60-7 n/a 220 142

n/a 60-12 220 142

75-9 75-9 220 142

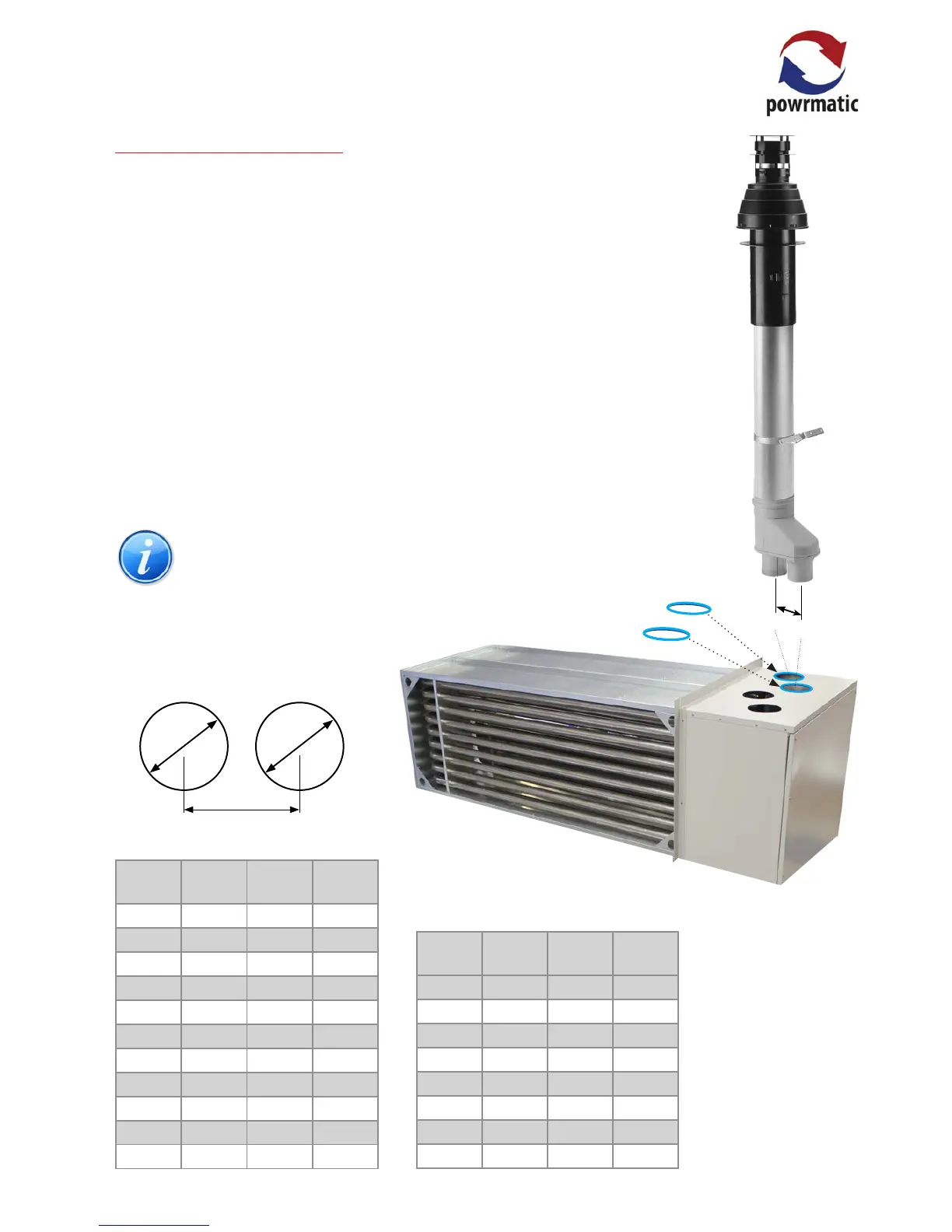

A CRS

ØD

ØD

Silicone

Seals

Simulated enclosure

A CRS

2.1.4.2 Type C Flued Installations

For vertical type C ued installations a vertical concentric

ue system should be used.

Nominal ue diameters are either 80mm, 100mm or

130mm dependent on heater size (refer to duties section

on page 6)

The maximum permitted length of ue system is 9m, If

an oset is required two sets of 45° bends should be used

each set being equivalent to 0.5m of ue length. 90° bends

may be used but each set will be equivalent to 1.0m of ue

length.

Exhaust ue outlet positions are shown in the previous

diagrams and tables.

Air inlet holes should be cut to the dimensions in the

following table to accept the silicone seals supplied.

(where ØD is the actual cut size in the casing/sheet metal).

The silicone seals supplied are not water tight

and should not be used in external vertical

applications. A suitable water tight seal or

sealant must be used in these instances.

HEMNVx HEMSL A CRS ØD

n/a 75-15 220 142

n/a 90-18 220 142

100-12 100-12 220 142

110-13 n/a 220 142

125-15 125-15 220 142

150-18 150-18 220 142

175-21 175-21 220 142

200-24 200-24 220 142

Type C Flue and air inlet cut hole sizes

and centres distances.

(refer to table below)

Loading...

Loading...