HEMNVx units should be serviced once per

year.

Gas Safety (Installation & Use) Regulations

(Current Issue)

It is law that all gas appliances are

installed, adjusted (converted if necessary)

and serviced by qualified persons* in accordance with

the current issue of the above regulations. Failure to

install appliances correctly can lead to prosecution.

It is in your own interests and that of safety to ensure

that the law is complied with.

* e.g. Gas Safe Registered

WARNING: Always switch o and disconnect

electricity supply and close the gas service

valve before carrying out any servicing

work or replacement of failed components.

The appliance manufacturer must be consulted

before replacing parts other than those

specied or recommended in the servicing

instructions.

Additional care must be taken if external units

are serviced in wet conditions. Consideration

must be given to additional requirements to

maintain a safe working environment e.g.

Weatherproof covers.

2.7.1. General

Full maintenance should be undertaken not less than

once per year by a qualied person. After any servicing

work has been complete, or any component replaced, the

air heater(s) must be fully commissioned and tested for

soundness as described in Section 2.2.

2.7.2. Main Burner Assembly Removal

1. Ensure that the gas service valve is turned OFF and then

unscrew the union nut situated immediately downstream

of it.

2. Remove the plug connection from the multifunctional

control.

3. Release the ange connections at the inlet and outlet of

the multifunctional control and remove the control.

4. Remove the spark and rectication probes from the side

of the burner noting which is which.

5. If required remove the burner manifold by removing the

four screws securing it to the burner assembly after having

rst removed the burner front cover.

6. Remove the four screws that secure the burner assembly

to the bulkhead and lift out burner assembly.

7. Using a sti brush, not a wire brush, brush the burners

to dislodge accumulated deposits. Inspect the burners

both internally and externally to ensure that they are clean.

Examine the injectors and if damaged or deteriorated,

replace with new ones of the correct size and marking. If

deemed necessary, clean the injectors. Do not broach out

with wire.

8. Inspect the heat exchanger tubes (See section 2.7.8)

9. Reassemble the injectors, manifold and burners in

reverse order to that above.

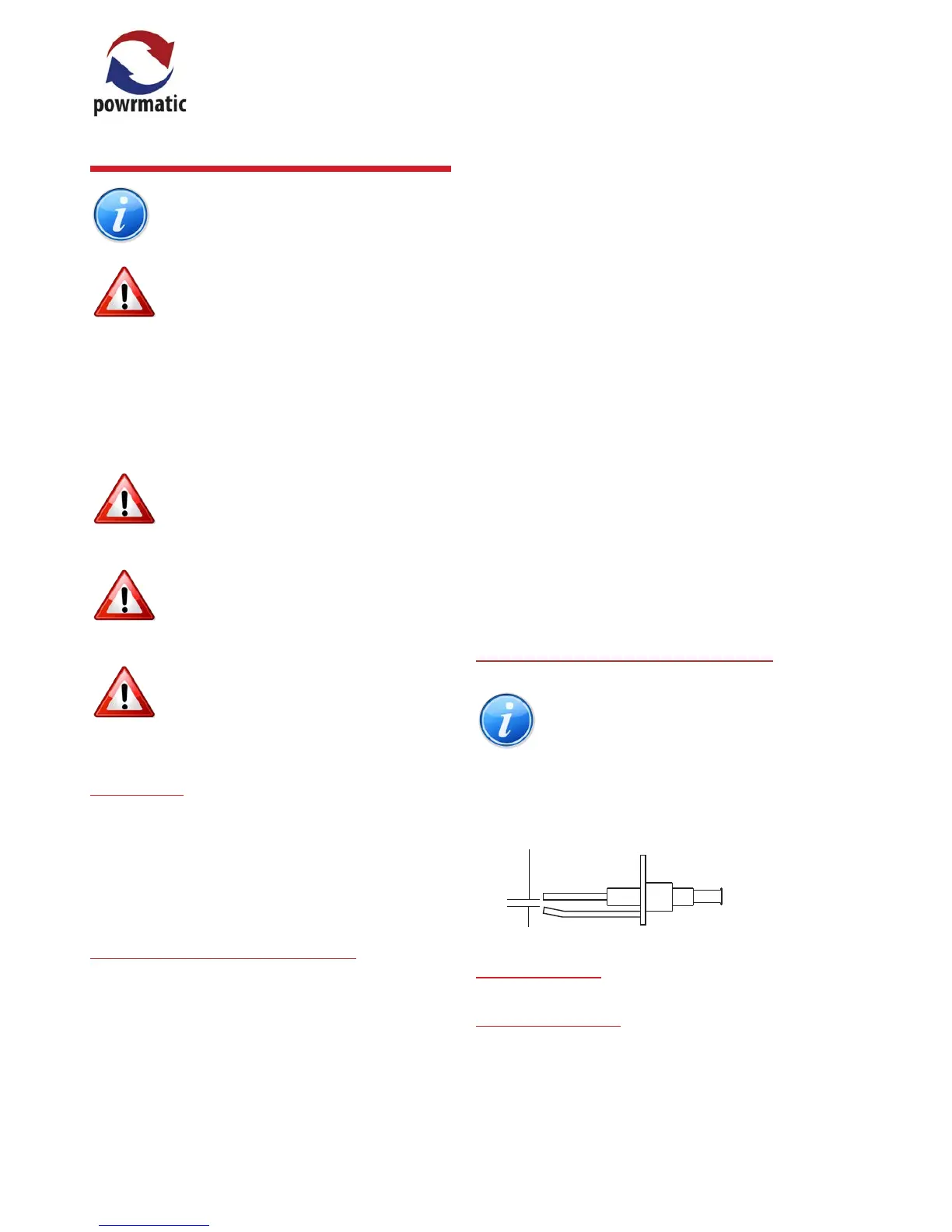

2.7.3. Ignition and Rectication Electrodes

Note: The ignition electrode is located at the

bottom of the burner assembly, the rectication

electrode is located at the top of the burner

assembly.

Inspect the electrodes, making sure that they are in a

sound and clean condition. In particular check that the

ignition electrode is clean and undamaged. Check that the

spark gap is 2.5mm and that the rectication probe is 10 -

12mm forward of the burner.

2.5mm

Ignition

Electrode Spark

Gap

2.7.4. Exhaust Fan

2.7.4.1. HEM 10 to 50

1. Disconnect the fan electrical connections from the main

terminal strip and the air pressure sensing tube from the

fan.

2. Loosen the six screws holding the main control panel,

lift the control panel up and clear of the xing position

(taking care not to snag the wiring) and move to one side.

2.7 Servicing

Loading...

Loading...