P/N SM1222

Rev 6

Print Date 2/14/2018

4 – STEP BY STEP SETUP PROCEDURE

When initially setting up a CD30, use the following steps.

NOTE: During initial setup if the controller’s on/off signal isn’t wired yet or is but isn’t being

sent, you must set –En = 1 (under menu C040) or place a jumper between contacts 5 & 6.

This will allow you to operate and run the controller without a run signal coming from a main

panel.

4.1 – WIRE CD30/35

Wire all connections to CD30/35, including:

• Incoming plant power

• Outgoing power to the conveyor coil

• The feedback sensor

• Along with any additional control wiring required for the application

NOTE: Reference section 3 for wiring specifics

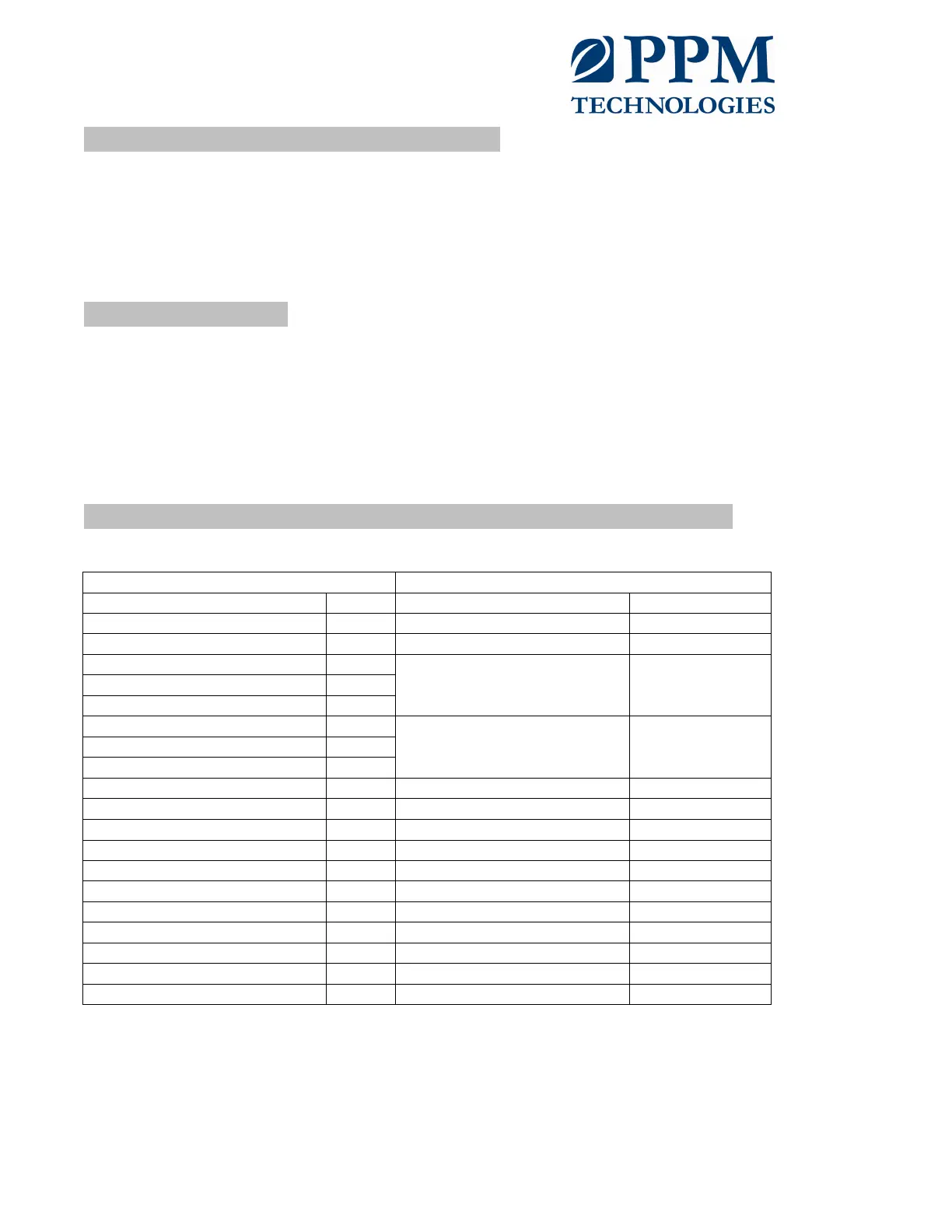

4.2 – INITIAL CD30/35 MENU SETTINGS FOR PPM EQUIPMENT

Note: settings that say “n/a” don’t matter for initial setup

I (current) 100 SIF (interface) 0

A (amplitude) n/a I (current) 100

P (power) n/a

L (low freq. limit)

VFA & Mini = 15

VFP & VFX = 10

Mag II = 25

F (frequency) n/a

ESP (External set point) 0

2. (2nd set point) n/a

H (high freq. limit)

VFA & Mini = 30

VFP & VFX = 20

Mag II = 35

ACC (loop control) 1

PA (proportional amplitude gain) 100

IA (integral amplitude gain) 100 F (actual freq.) n/a

AFC (auto freq. control) 1 AS (AFC threshold) 25

AFS (start freq. search) Squiggle up (soft start) 0

Squiggle down (soft stop) 0.1

-En (invert enable) 0

Efu (current regulation) 0

PI (prop current regulation) 20

II (Integral current regulation) 40

rb (status relay) 0

SPE 0

APS 1

Loading...

Loading...