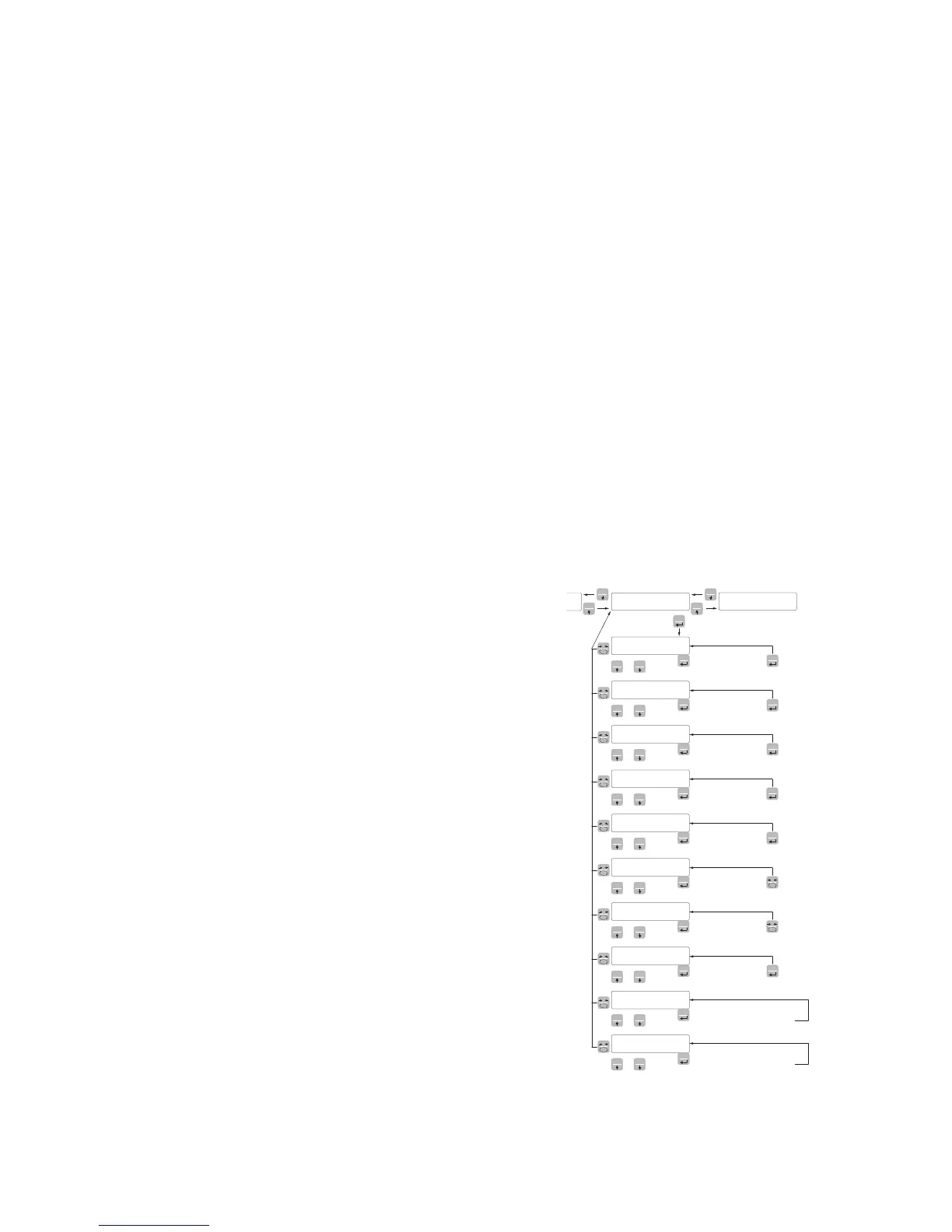

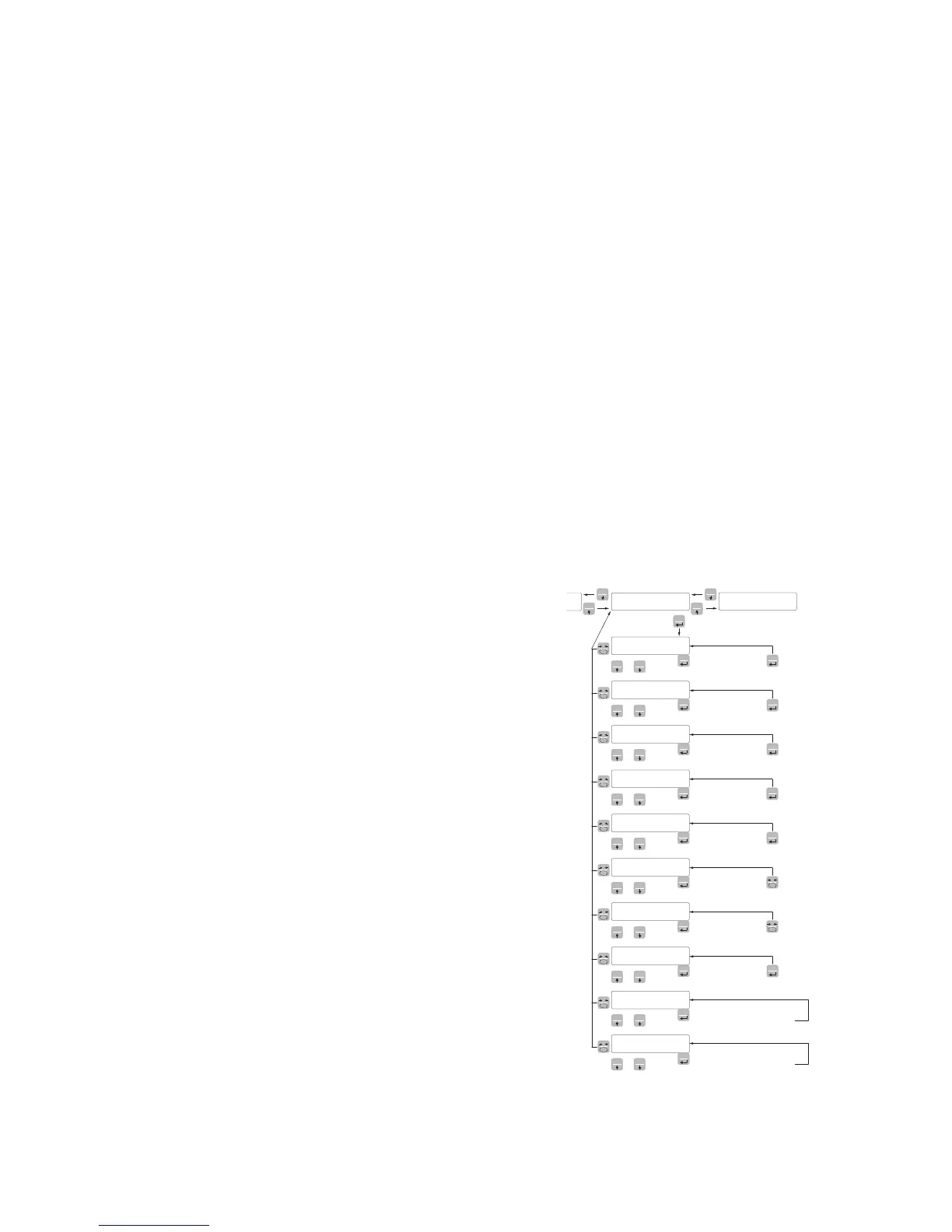

CapaC

SEns1t

nEt

dEad L

dspd1J

S1GnaL

CoUnts

opNodE

UpLoad

dnLoad

SET FUN

0

0

0

0

0

0

0

0

0

0

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET FUN

SET

FUN

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Select Value

PRG

PRG

Read Value

PRG

Read Value

PRG

Select Value

PRG

PRG

PRG

Transmit setup data

to serial port

0

0

Receive setup data

from serial port

CONFIGURATION PARAMETERS

Through the setting of the parameters listed below, the theoretical Full Scale DAT 400 calibration is

performed. These steps with the zero calibration described on the next page must be completed. The

procedure ensures a good accuracy of the system (maximum error <1% FS) if there are no mechanical

problems.

Program the known values of total capacity and sensitivity of the load cells and the approximate values

of net capacity and calibration. If the parameter SENSIT is not programmed, it is taken the 2.0000

mV/V value.

If the parameter CAPAC is programmed other than 0, according to the data CAPAC, SENSIT, NET and

DEAD L , the instrument automatically runs the following functions:

Resetting the linearization points.

Selection of the value of the division, however, to be modified, to the best of 10,000 divisions.

Calibration of the theoretical approximate calibration of the weight (zero and full scale).

Automatic programming of the overload setpoint (= NET).

These functions are performed each time you change one of the 4 parameters shown.

When you change the DSPDIV selection., it is automatically recalculated to full-scale calibration. The

selections are incompatible with the calibration parameters or calibration in memory are not accepted.

The selection programmed in Opmode is read from the instrument when it is switched on and it makes

that the instrument operates in that way.

CAPAC CAPACITY OF THE WEIGHING SYSTEM

It defines the value corresponding to the sum of the rated capacity

of the load cells. In the case of systems with only one load cell and

“N” fixed supports, enter the capacity value of the cell for the total

number of supports. This figure represents the full scale value of the

weighing system.

Following the change of the parameter value, the theoretical tare of

the weight is recalculated.

Values: from 1 to 500000

Unit: the same of that displayed

Default: 10000

sEnsit LOAD CELLS SENSITIVITY

Set the value corresponding to the average sensitivity of the load

cells, in mV / V. The instrument accepts values between 0.5 and 4

mV / V. If no value if programmed, it’s assumed it is 2mV/V.

Following the change of the sensitivity value, the theoretical tare of

the weight is recalculated.

Values: from 0.5000 to 4.0000 mV/V

Default: 2.0000

Loading...

Loading...