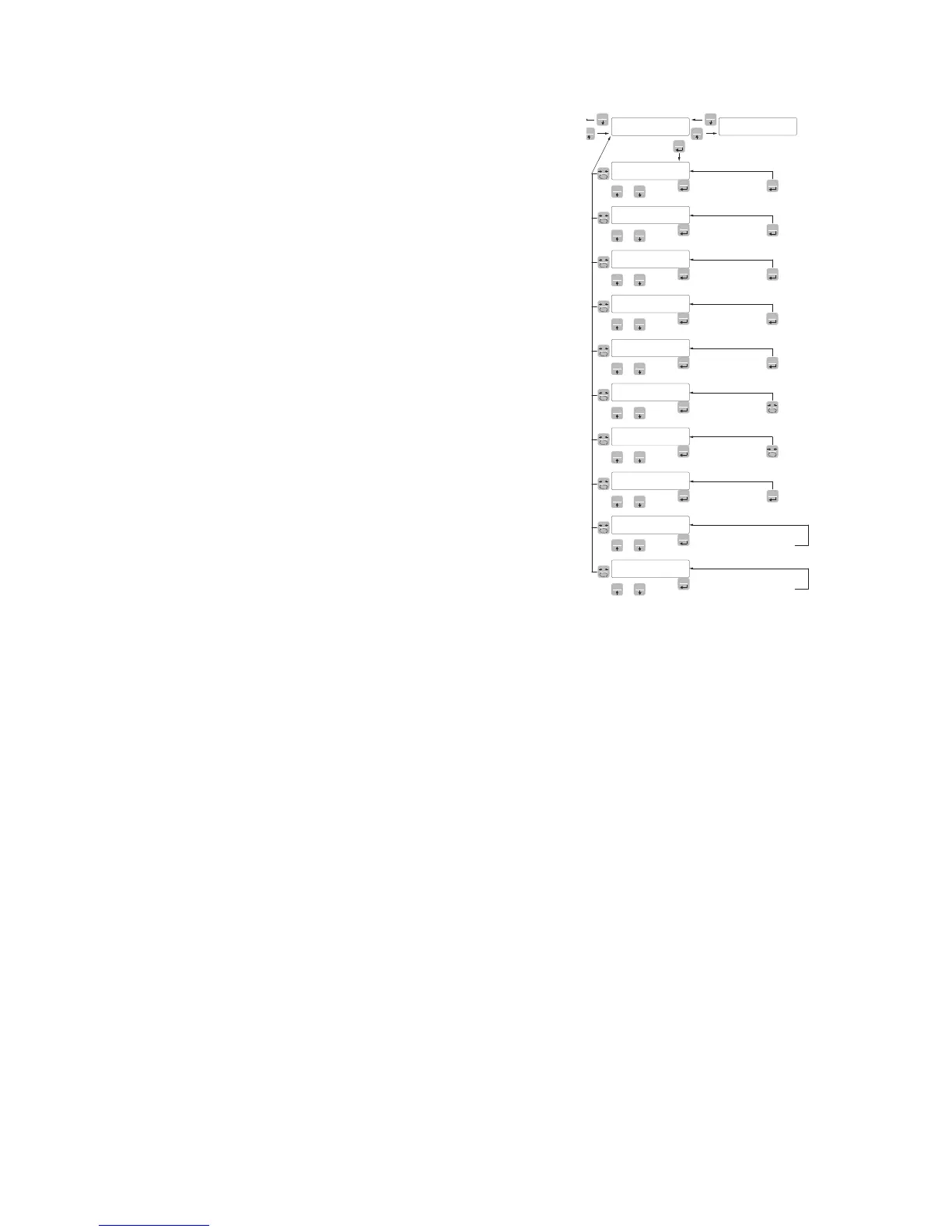

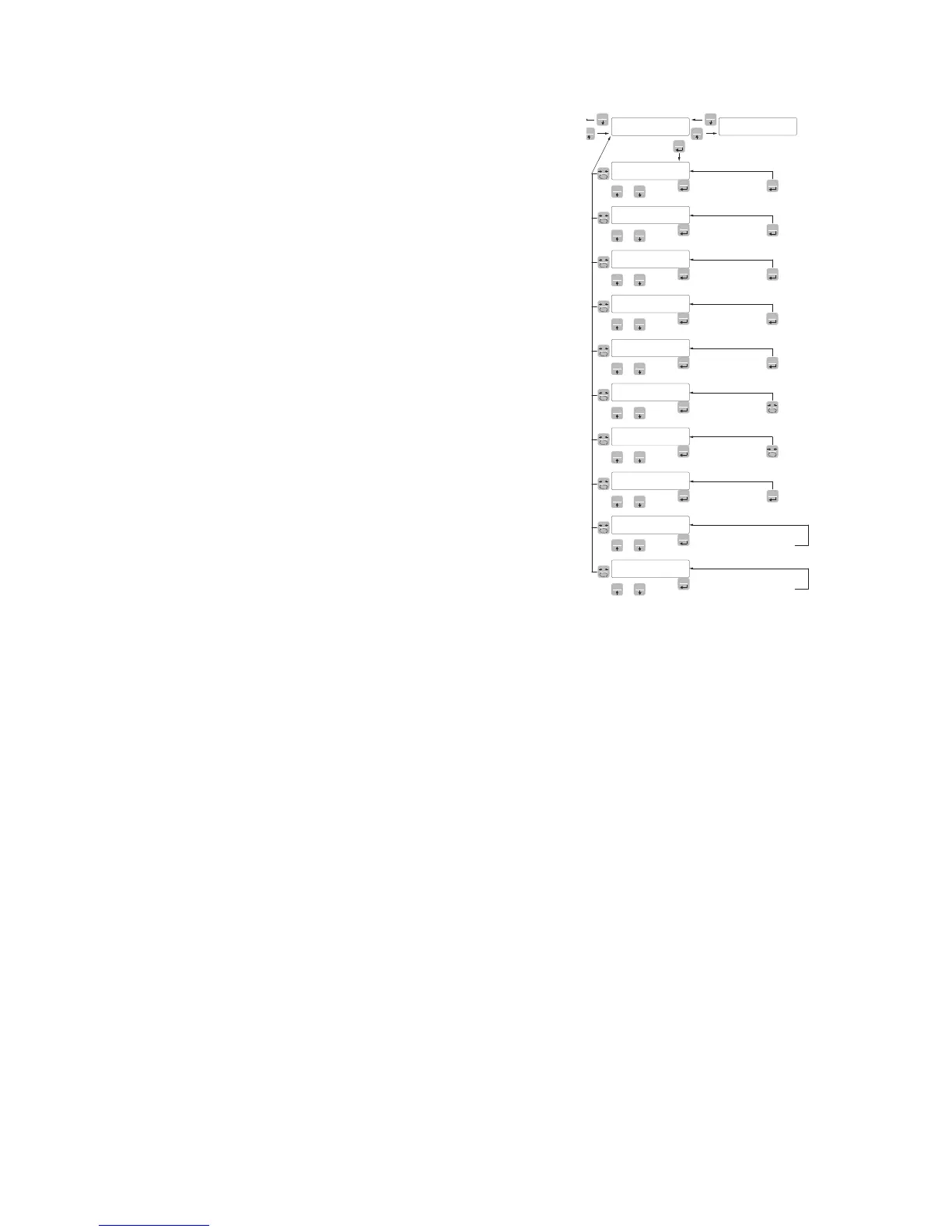

FUN

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Enter Value

PRG

PRG

Select Value

PRG

PRG

Read Value

PRG

Read Value

PRG

Select Value

PRG

PRG

PRG

Transmit setup data

to serial port

0

0

Receive setup data

from serial port

UpLoad RECEIVING DATA FUNCTION

Receiving function from a serial of a file containing the setup data

that will be automatically set in the instrument.

dnLoad SENDING DATA FUNCTION

Sending function from a serial of a file with the content of the setup

memory of the instrument.

EXAMPLE OF SETTING/CALIBRATION

To weigh a tank, with empty weight of 750 kg and with a capacity

of 1000 liters, containing a product with a specific gravity of 1.33

to read the weight with a display resolution of 0.2 Kg.

Before proceeding with the configuration, make sure that the load

cells are connected properly to the unit and the tank is empty and

set the parameters.

They are used:

Nr 3 load cells with capacity of 1000 kg

Sensitivity of respectively 2.0015, 2.0008 and 1.9998 mV/V (ave-

rage value = 2.0007 mV/V)

Set the following values in the configuration parameters:

CapaC = 3000

sEnsit 2.0007

NEt 1500

dEad L 0

dsPd1J 0.2

Make sure that the value read in the SIGNL parameter corresponds

with the calibration weight of the system according to the following

proportion:

3000:2.0007=750:X

Where X is the value of the signal expressed in mV/V corresponding

to the theoretical value of the weight of the empty tank. The value

should be about 0.5 mV/V.

Proceed to the calibration described in the following paragraph,

or you can exit the configuration menu by saving the data entered.

The instrument should indicate the value corresponding to the weight

of the empty tank (for example 756.8).

Re-access the configuration menu and enter the weight value read

in the dEad L parameter and enter the value 756.8.

Quit the configuration menu by saving the data.

For greater accuracy, prepare some sample weights or the pre-

weighed material on a certified system and calibrate as described

in the next paragraph.

Loading...

Loading...