20

LAYOUTOPERATION

Helpful Hint: If diculty is observed in starting the arc, it may be time to readjust the point

gap setting found inside. The HF points tend to wear and get dirty over time. This is a

normal maintenance item and not something for warranty consideration. Proper point gap

adjustment is .035 “to .045”. Before attempting to adjust the point gap, be sure to unplug the

unit for 15 minutes before removing the rear plastic panel, and the steel case to access the

points located near the front of the unit. Do not remove the front panel! Use a feeler gauge to

adjust the points to the proper setting. Another possibility is that the air pressure is too low or

too high. Worn/loose consumables may cause this as well.

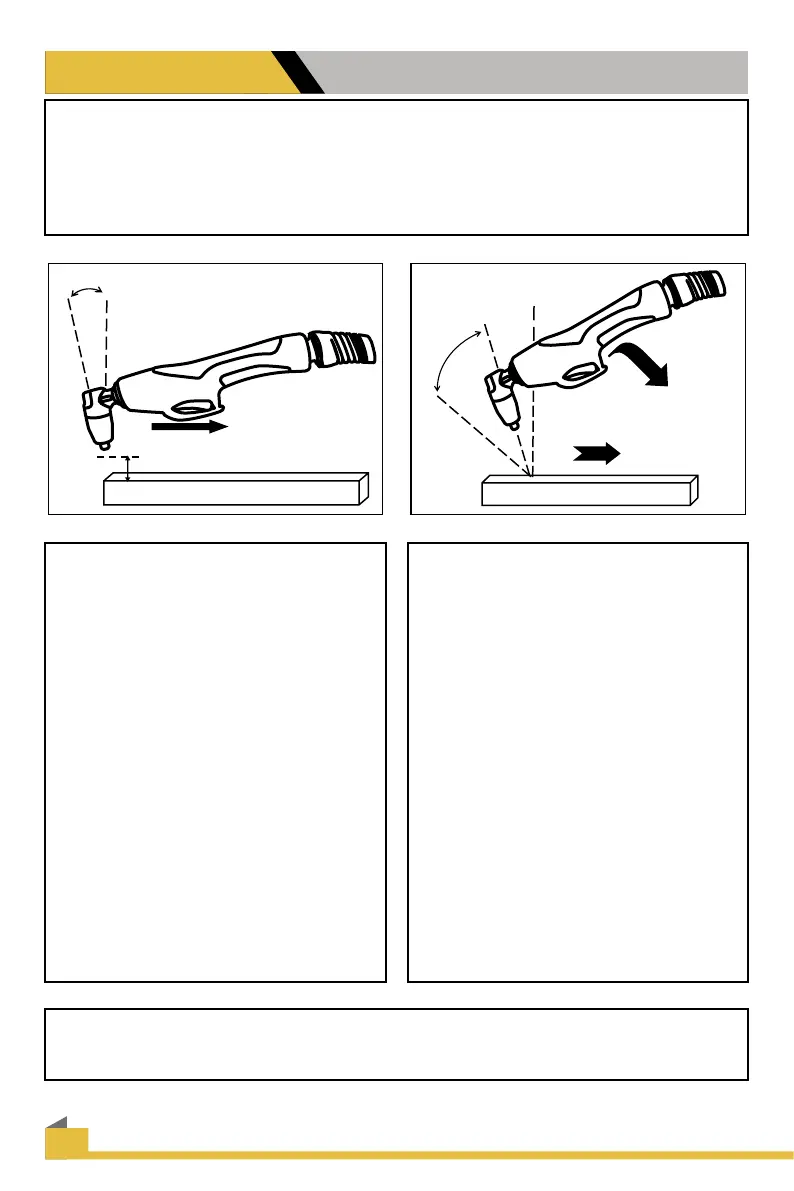

0°-15° EDGE START

TRAVEL

1/16”

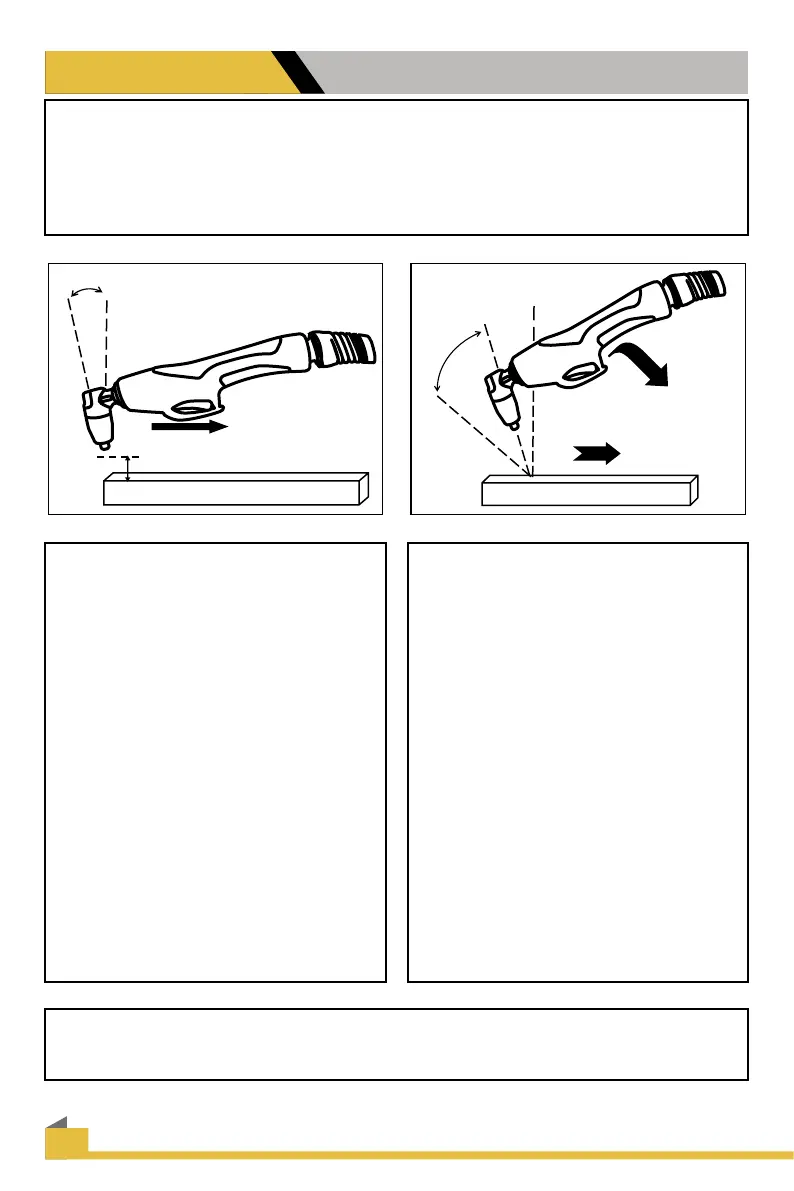

40°-60°

PIERCE START

TRAVEL

Edge Starts are the best type of start if

possible to promote consumable and torch

life. This reduces blow back of molten

material and allows a smooth gradual start

of the cut. 1. Line up the hole on the tip

of the electrode on the edge of the cut.

Hold torch perpendicular to the cut initially,

about 1/16” o the metal. 2. Once the

arc starts, wait for the arc to penetrate all

the way through the metal. 3. As the torch

penetrates its ame all the way through

the metal, tilt the torch so there is a slight

lead in the ame if metal is thin. If it is

thick, keep holding torch in a nearly vertical

position. 4. Begin moving the torch in the

direction of the cut. Maintain 1/16” stando

height. 5. Move the torch fast enough so the

sparks and ame trail from the bottom edge

at an angle of no more than 30° and no less

than 10° from perpendicular to the metal.

Excess angle of sparks/ame indicate too

fast of travel speed or practical cut capacity

has been reached. Little or no angle

indicates too slow of travel speed.

IMPORTANT

Piercing starts often result in rapid

consumable wear and excess blow back

of molten metal deposited onto torch and

consumables. This should be done only as

necessary. 1. Tilt the torch in the direction

of travel or toward the side of the metal

to be discarded or wasted at a 40° to 60°

angle. Slide the yellow safety lock and

squeeze the trigger. 2. Once the arc starts,

wait for the arc to transfer from pilot arc to

the cutting arc. 3. As the torch penetrates it

ame at an angle rotate the torch slowly to

the vertical position, as the arc penetrates

the metal. Tilt the torch from 0°-15° for thin

metal cuts, or hold it nearly perpendicular

for thicker metal cuts. 4. Begin moving the

torch in the direction of the cut. Maintain

1/16” stando height. 5. Move the torch

fast enough so the sparks and ame trail

from the bottom edge at an angle of no

more than 30° and no less than 10° from

perpendicular to the metal. Excess angle

of sparks/ame indicate too fast of travel

speed or practical cut capacity has been

reached. Little or no angle indicates too

slow of travel speed.

Helpful

IMPORTANT: If you use a stando guide with the torch, it must be adjusted or bent to

provide no more than 1/8” stando, less if possible. Long stando heights reduce cut capacity

and quality. It also promotes rapid consumable wear and can prevent the pilot arc from

transferring.

Loading...

Loading...