27

LAYOUTOPERATION

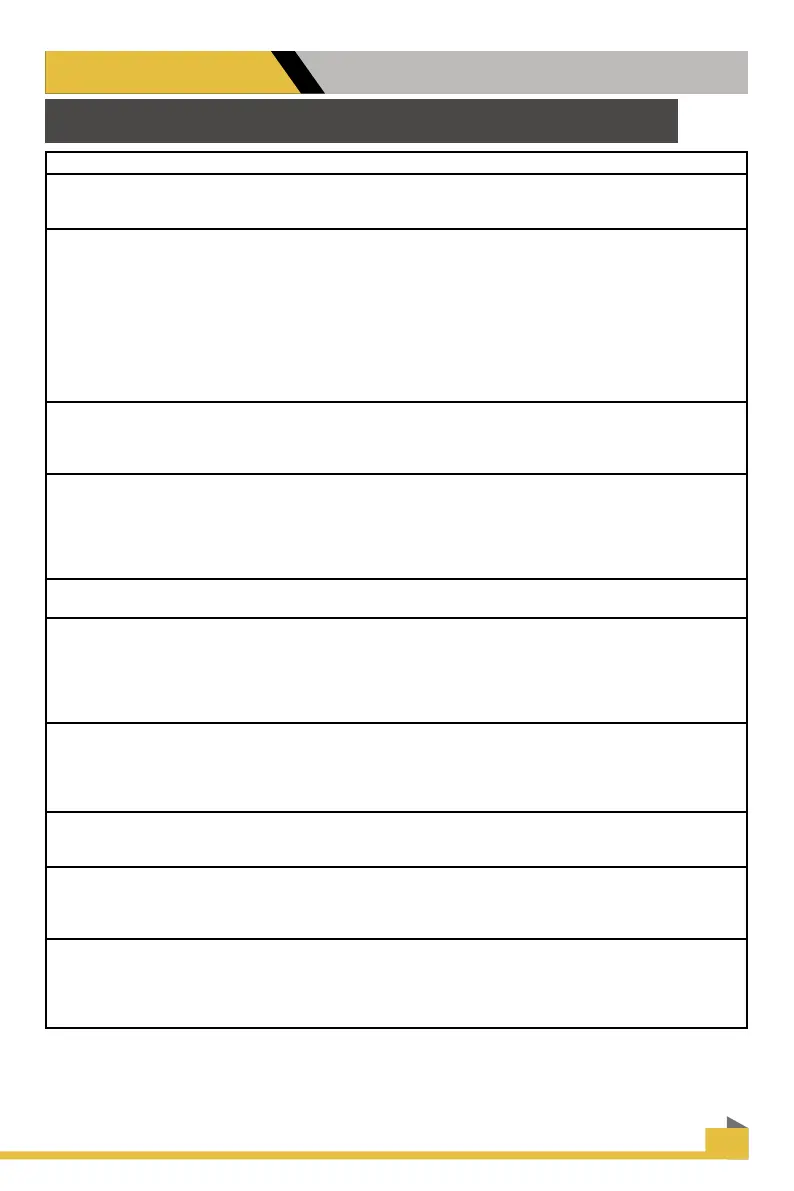

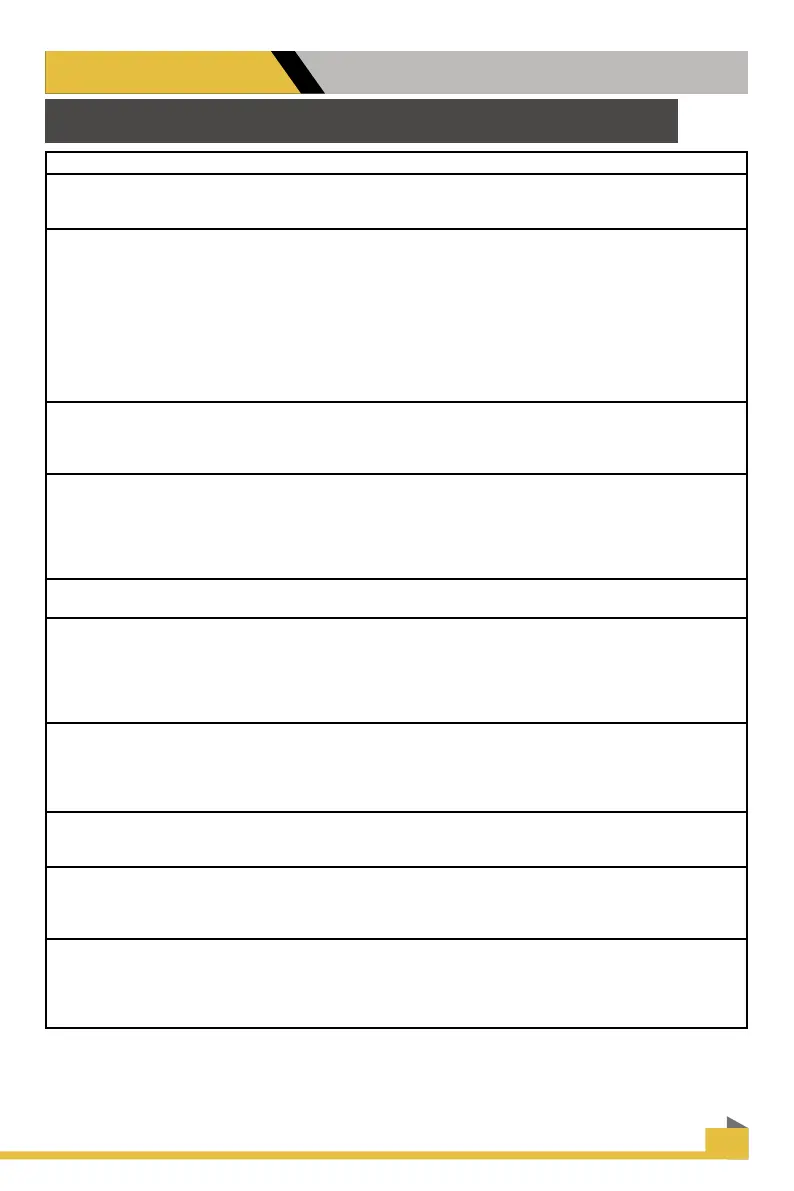

FRONT PANEL FEATURES AND CONTROLS CONTINUED

FEATURES PARAMETERS PURPOSE

1. Amp Display N/A

Indicates actual amp output while welding. While adjusting

or while not welding, the function of the display changes to

display the selected amperage.

2. On/Temp/ Duty

Cycle

On/O

The On indicator should always be lit while the unit is

plugged in and the power switch is switched on. If the

Overcurrent light is lit, turn the unit o and check for possible

causes including undersized cables, poor connections and

overheating cables. If the Duty cycle is lit, do not turn

o the unit until it has had sucient time to cool (10-15

minutes). Cycle the power switch to reset the machine only

after the machine has had time to cool. The duty cycle and

overcurrent warning lights should go o after cycling the

power switch on the machine. If it does not, contact.

3. Panel/Pedal

Switch

N/A

This switch determines which mode controls the unit, the

torch switch (Panel) or the pedal. Using either one will

determine how the unit reads and sets the maximum output

of the machine.

4. TIG/CUT/

STICK

N/A

This switch selects processes. Do not switch this switch

while welding or cutting, Do not switch it with the wrong

torch connected or immediate failure of the unit may result.

Improper polarity can contribute to torch failure as well. Make

sure all connections are installed properly before cutting or

welding.

5. Amp Control N/A

Controls amperage while welding or cutting by using the knob

to preset maximum amperage.

6. Post Flow

Control

2-8 Seconds

Sets the post ow time of the shielding gas while welding in

TIG mode. While in plasma (cut) mode, it sets the post ow

time of the air. Time is an approximation only and can vary a

little from the setting posted on the dial. The air or shielding

gas may stop owing before full maximum time is reached.

Consider the maximum setting mark a reference guide only.

7. Pilot Arc N/A

This connection is only used with the plasma cutting torch.

The small ringed wire connects here. Unscrew the plastic

thumb nut and attach the wire to the post. Reinstall the

thumb nut over the wire with nger pressure only. Do not

overtighten

8. Negative

Connector

DINSE 25

Location of the negative terminal connection. Dinse-style. For

Stick: Work Clamp Connection. For TIG: Torch Connection.

For Plasma: Torch Connection.

9. Quick Connect

Gas Outlet

9mm

Connects the shielding gas to the TIG torch. To connect:

Push the torch tting into the connector until the collar slides

forward with a click. To Release: Slide the collar back and it

will automatically release. Do not turn or twist the connector.

10. Control

Connector

5 Pins

Connect the foot pedal or torch switch to this socket to

control the welder. Only the foot pedal or torch control

connector can be plugged in at one time. If the torch has a

torch switch feature, tie the loose connector back and leave it

disconnected while using the pedal.

Loading...

Loading...