60 Gallon Single Stage Stationary Air Compressor

10

For technical questions call 1-800-665-8685

8475006

V 1.6

MAINTENANCE SCHEDULE

TASK INTERVAL

Check Pump Oil Level Daily

Operate the Pressure Relief Valves Daily

Drain Tank Daily

Check for Unusual Noise or Vibration Daily

Check for Air or Oil Leaks Daily

Inspect Belt Guard Daily

Inspect and Clean Air Filter Weekly

Change Pump Oil

Every 200 hours or 1 year

Check Belt Tension

Monthly or every 50 hours

Check and Tighten All Bolts After first 8 hours and every 500 operating hours

Check Operation of System Controls Every 3 months

Check Air tank for Dents/Leaks Every 3 months

LUBRICATION

Inspect and lubricate the device when required.

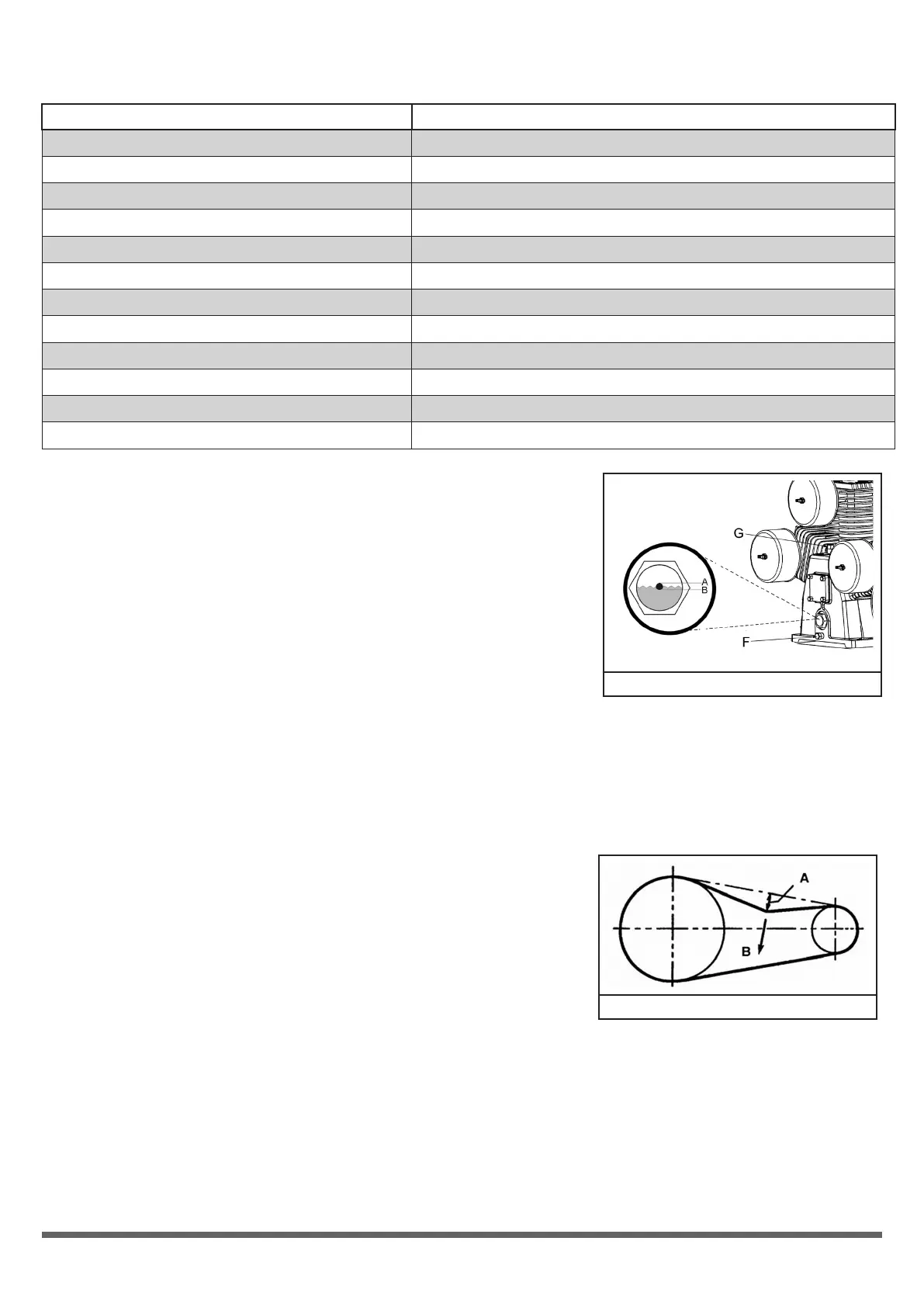

CHECKING THE OIL

Prior to daily operation, check the oil level in your compressor

pump. Check the sight glass to ensure the level is between A and

B. The optimal level is 2/3 full on the sight gauge. Do not operate

the pump with an inadequate or excessive amount of oil.

NOTE: Use synthetic, non-detergent air compressor oil.

CHANGING THE OIL

1. Remove the oil plug (F) and drain the oil until it slows to a drip, then close (Fig. 6).

2. Add oil to the pump by first removing the breather plug(G).

3. Add oil (approx. 40 oz/1.18 litres) until the level viewed through the sight glass is between

FULL (A) and ADD(B).

4. Replace the breather plug.

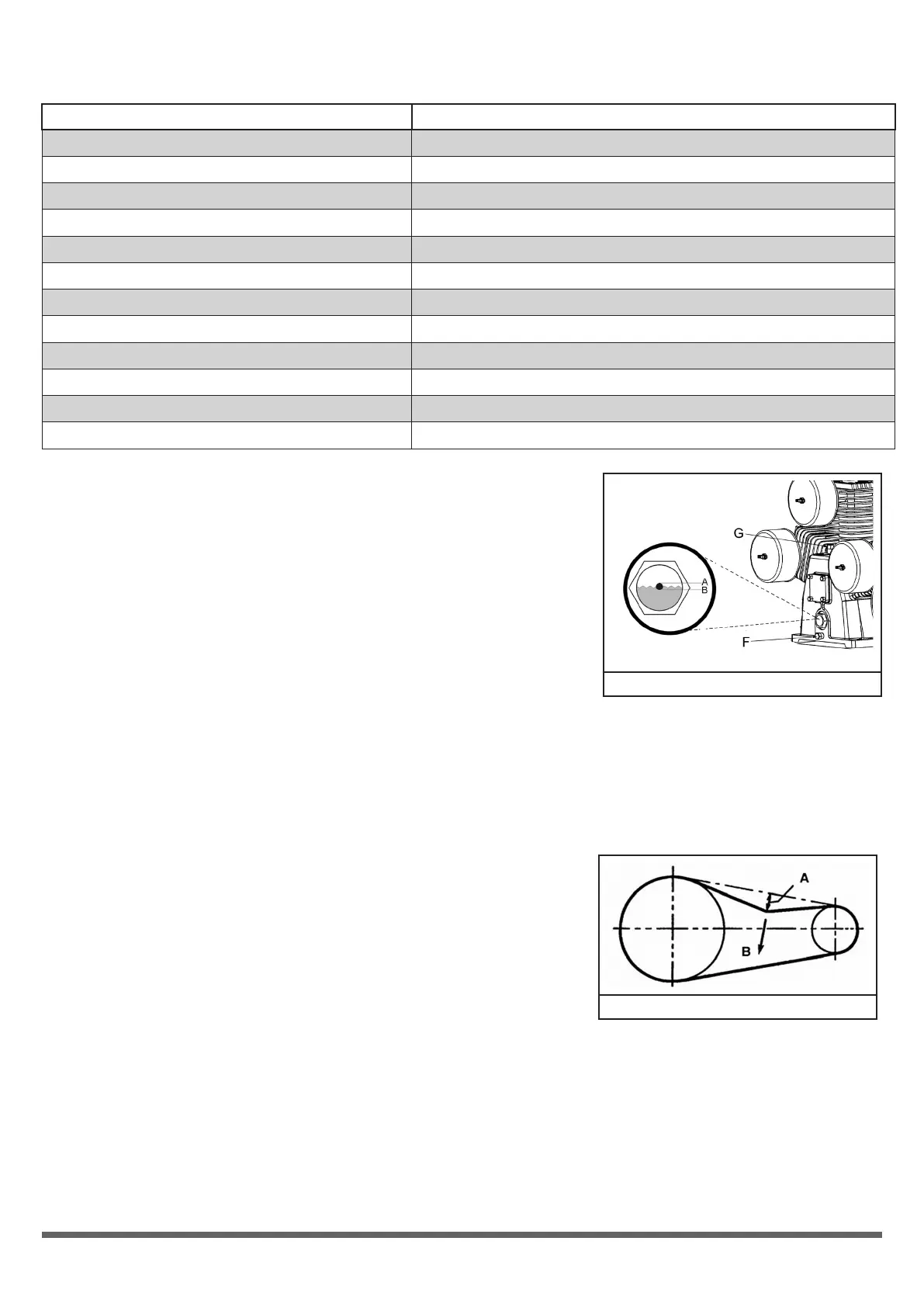

BELT-TIGHTENING DEVICE

Drive belt tensioning and pulley alignment are done at the same

time. They are discussed separately for clarity.

Proper belt tension and pulley alignment must be maintained for

maximum drive eciency and belt life. The correct tension exists

if a deflection (A) of 1/2 in. (13 mm) occurs by placing 10 lb

(4.6 kg) of force (B) midway between the motor pulley and the

pump flywheel (Fig. 7). This deflection can be adjusted by the

following procedure. The pulley should be carefully aligned with

the flywheel and all set screws should be kept tight.

1. Remove the belt guard.

2. Loosen the motor mounting bolts.

3. Shift the motor to the point where the correct deflection exists.

4. Retighten the motor mounting bolts.

5. Check to ensure that the tension remained correct.

6. Reinstall the belt guard. All moving parts must be guarded.

Fig. 6

Fig. 7

Loading...

Loading...