60 Gallon Single Stage Stationary Air Compressor

12

For technical questions call 1-800-665-8685

8475006

V 1.6

DISPOSAL

Recycle a device damaged beyond repair at the appropriate facility.

Contact your local municipality for a list of disposal facilities or by-laws for electronic devices,

batteries, oil or other toxic liquids.

IMPORTANT! DO NOT pollute the environment by allowing uncontrolled discharge of waste oil.

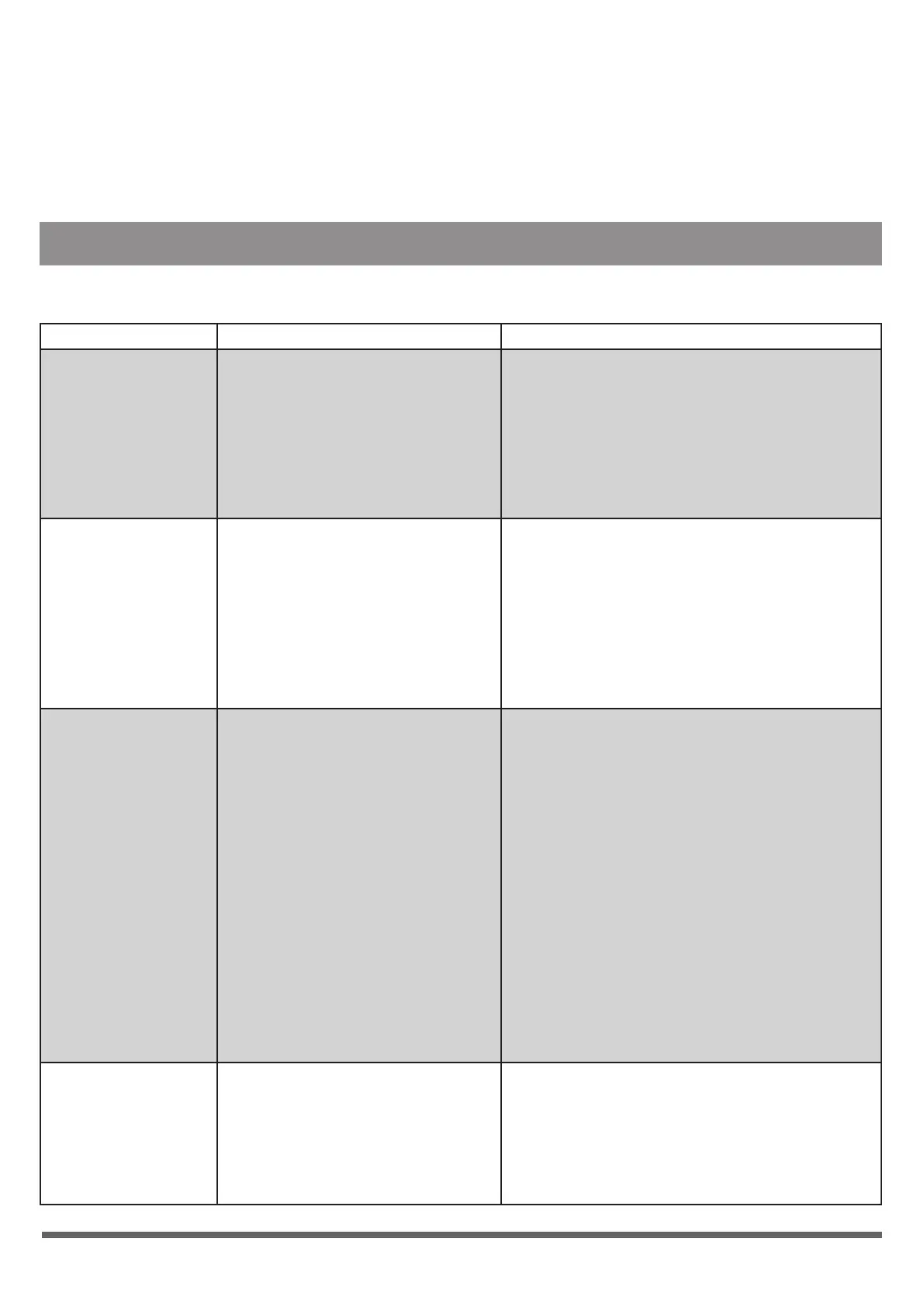

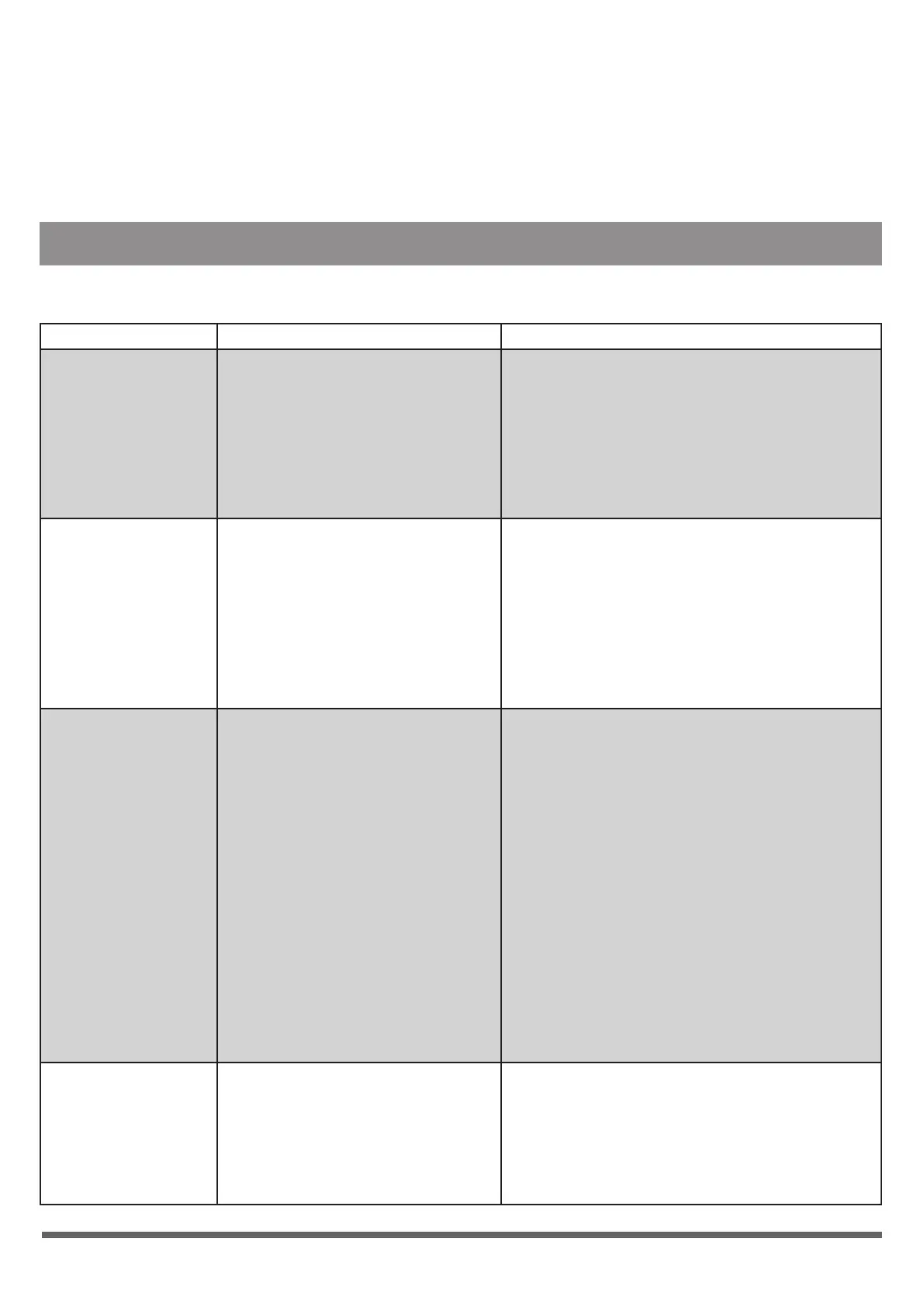

TROUBLESHOOTING

Contact Princess Auto Ltd. for a solution if the device does not function properly or parts are

missing. If unable to do so, have a qualified technician service the device.

Problem(s) Possible Cause(s) Suggested Solution(s)

Pump is slow to

build

tank pressure.

1. Loose/slipping belt.

2. Leaks in system.

3. Blown gasket.

4. Broken reed valve.

5. Obstructed intakefilter.

6. Leaking regulator.

7. Defective pressure

reliefvalve.

1. Adjust belt tension.

2. Correct air leaks.

3. Replace head gaskets.

4. Replace reed valves.

5. Clean or replace intakeelement.

6. Replace regulator.

7. Replace pressure reliefvalve.

Excessive oil

consumption.

1. Too much oil in crankcase.

2. Improper weight ofoil.

3. Obstructed

crankcase vent.

4. Dirty/plugged intake filter.

5. Worn piston rings.

6. Scored cylinder.

1. Drain to proper level.

2. Replace with proper oil.

3. Replace dipstick or oil fill plug/

crankcase vent.

4. Clean/replace intake filter.

5. Contact Princess Auto Ltd.

for solution.

6. Contact Princess Auto Ltd.

for solution.

Low discharge

pressure.

OR

Compressor does

not stop.

1. Tank drain valve isopen.

2. Air leaks.

3. Restricted air intake.

4. Prolonged excessive use

ofair.

5. Compressor not

largeenough.

6. Tank leaks.

7. Blown seals or gaskets.

8. Leaking/worn piston rings

orcylinder.

1. Close drain valve.

2. Tighten or replace leaking fittings or

connections (do not overtighten).

Check air hose. Replace parts

ifnecessary.

3. Clean or replace air filterelement(s).

4. Decrease amount of airused.

5. Check air requirement of accessory.

If it is higher than CFM and pressure

supplied by compressor, you need a

larger compressor. Most accessories

are rated at 25% of actual CFM while

running continuously.

6. Immediately replace tank. DO NOT

attempt to repair.

7. Replace seals or gasket.

8. Replace piston ring orcylinder.

Air leaks

fromregulator.

Or

Regulator does

not

regulate pressure.

Dirty or damaged regulator

internal parts.

Replace regulator or internalparts.

Loading...

Loading...