60 Gallon Single Stage Stationary Air Compressor

13Visit www.princessauto.com for more information

8475006

V 1.6

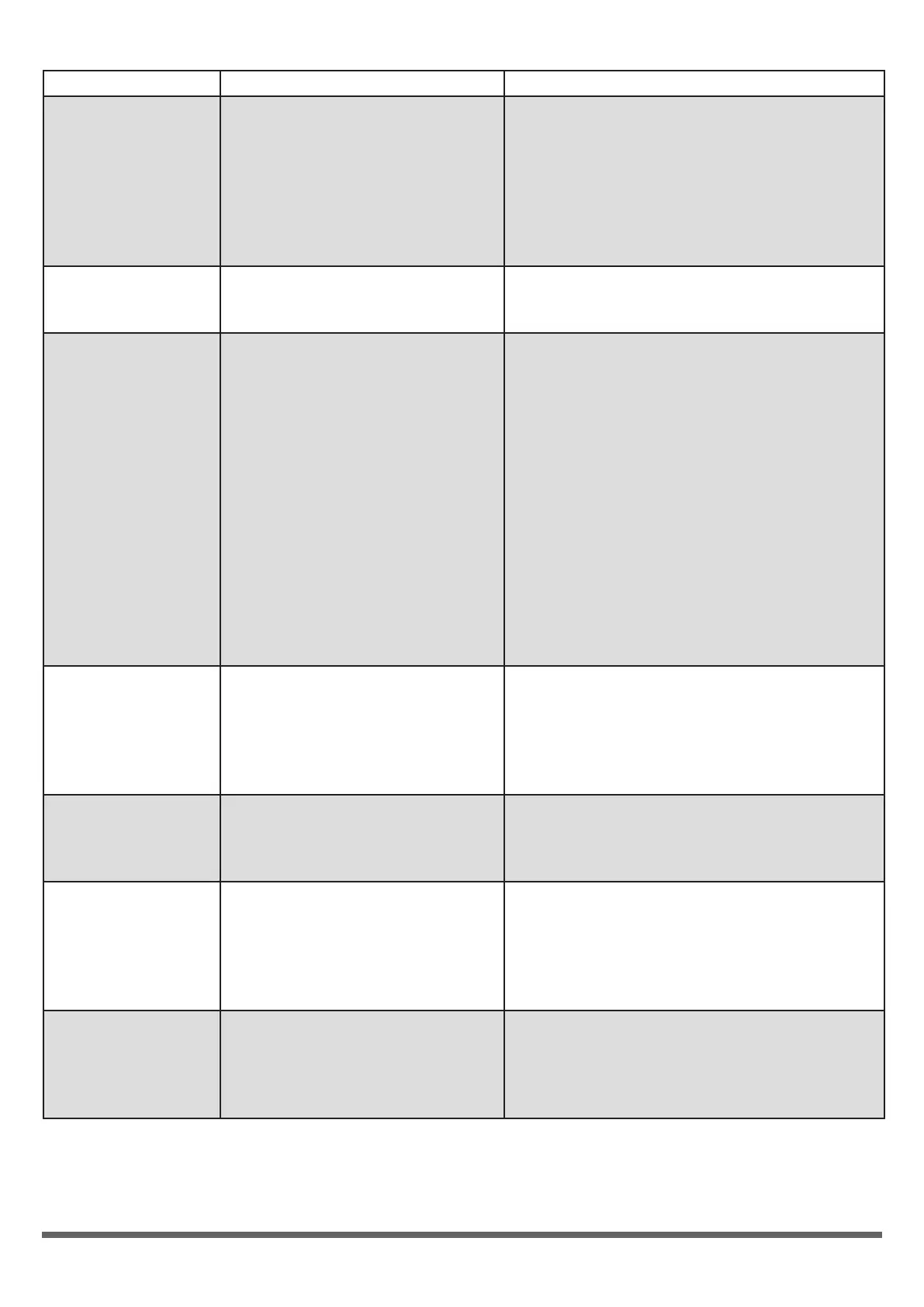

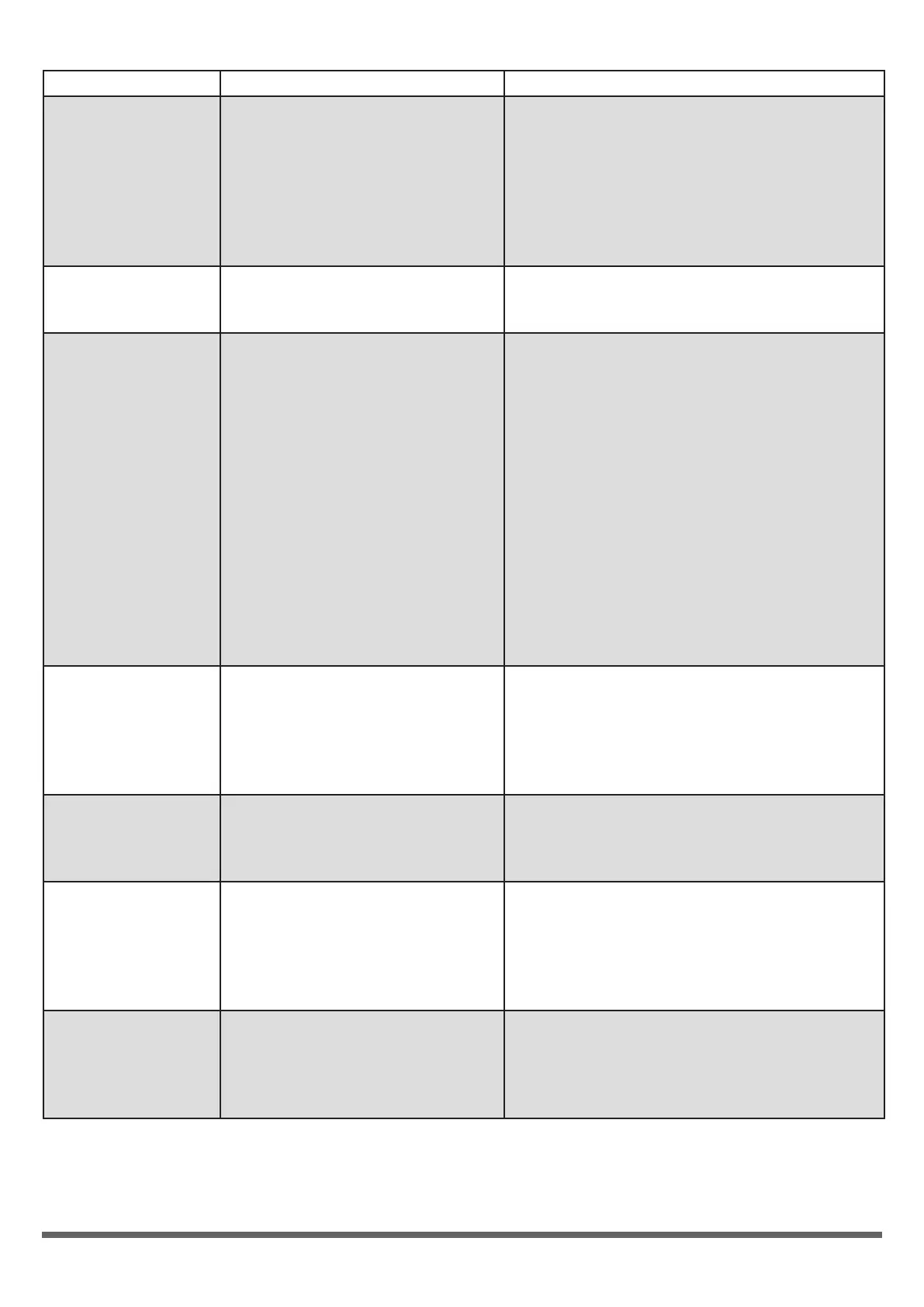

Problem(s) Possible Cause(s) Suggested Solution(s)

Regulated

pressure gauge

reading drops

when air accessory

is beingused.

1. This is normal.

2. Compressor not

large enough.

1. If pressure drops too low, adjust air

tool regulator while accessory is used.

2. Check air requirement of accessory.

If it is higher than CFM and pressure

supplied by compressor, you need a

larger compressor. Most accessories

are rated at 25% of actual CFM while

running continuously.

Pressure relief

valveopens.

1. Tank pressure exceeded

normal operating pressure.

2. Pressure switch stuck.

1. Replace pressure switch.

2. Replace pressure switch.

Motor will notrun. 1. Tank pressure exceeds

preset pressure

switchlimit.

2. Check valve stuckopen.

3. Wrong wire gauge in

power line.

4. Loose electrical

connections.

5. Paint spray on internal

motorparts.

6. Possible defective motor.

1. Motor will start automatically when

tank pressure drops below

cut-in pressure of

pressure tank.

2. Remove and clean

or replace.

3. Check for proper gauge for

distance between power source

andcompressor.

4. Contact Princess Auto Ltd. for

asolution.

5. Have checked at service center. Do

not operate compressor in the paint

sprayarea.

6. Contact Princess Auto Ltd. for

asolution.

Excessive current

draw trips

circuitbreaker.

1. Low voltage/

motor overload.

2. Drive belt too tight.

3. Restricted air passages.

1. Check that power supply is adequate

and that compressor is on a

dedicated circuit.

2. Readjust belt tension.

3. Inspect and replace transfer tubes or

check valve, asrequired.

Compressor stalls. 1. Low voltage motor.

2. Bad check valve.

3. Seized pump.

1. Furnish adequate power.

2. Replace the check valve.

3. Contact Princess Auto Ltd. for

asolution.

Compressor

pump knocking.

1. Loose engine pulley or

compressor flywheel.

2. Low oil level in

pumpcrankcase.

3. Excess carbon on valves

or top ofpiston.

1. Retighten pulley and flywheel.

Checkalignment.

2. Keep oil at proper level at alltimes.

3. Contact Princess Auto Ltd.

for a solution.

Oil in dischargeair. 1. Worn piston rings

orcylinder.

2. Restricted air intake.

3. Oil level too high.

1. Contact Princess Auto Ltd.

for a solution.

2. Clean or replace the air

filterelement(s).

3. Reduce to proper level.

Loading...

Loading...