60 Gallon Single Stage Stationary Air Compressor

14

For technical questions call 1-800-665-8685

8475006

V 1.6

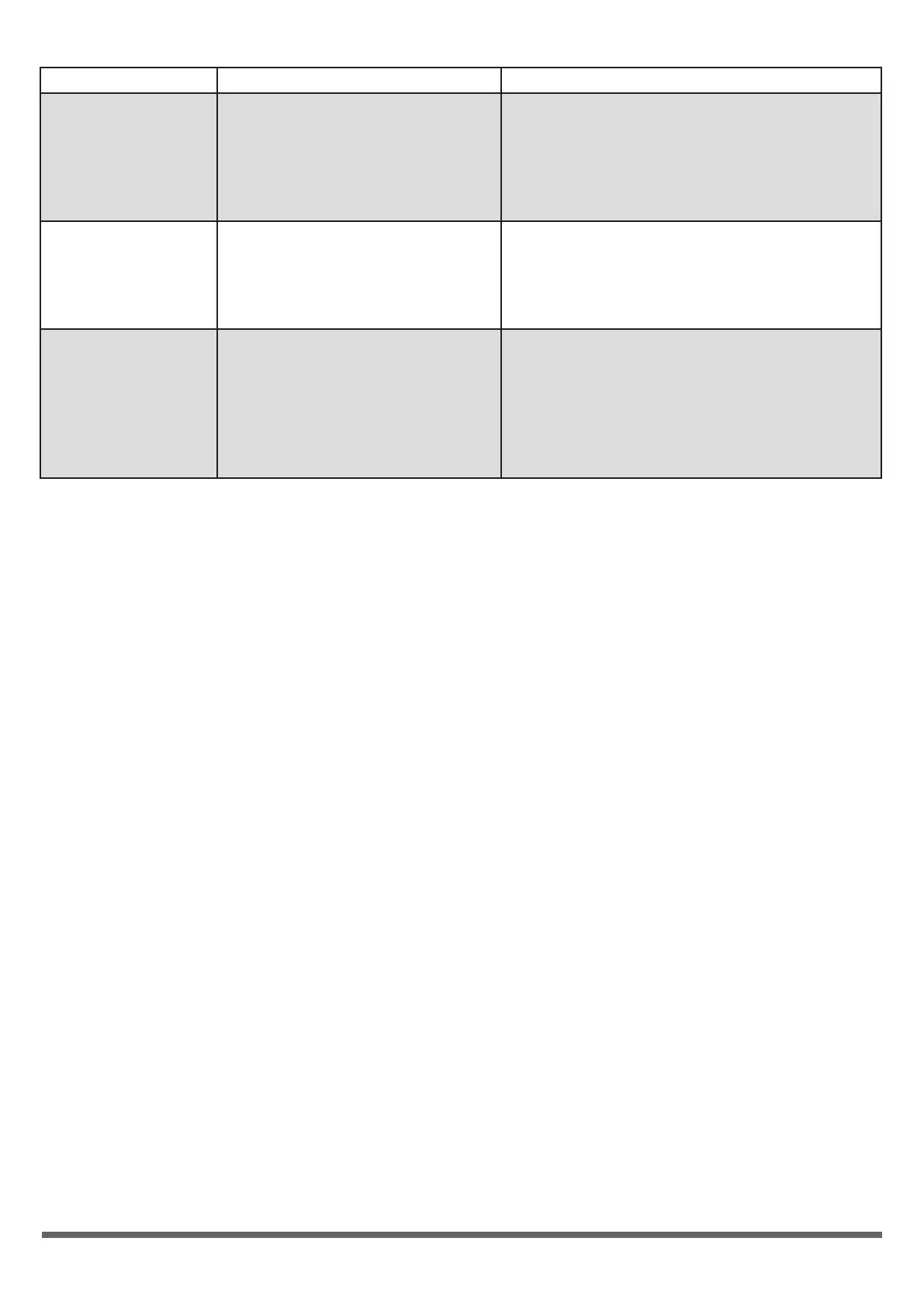

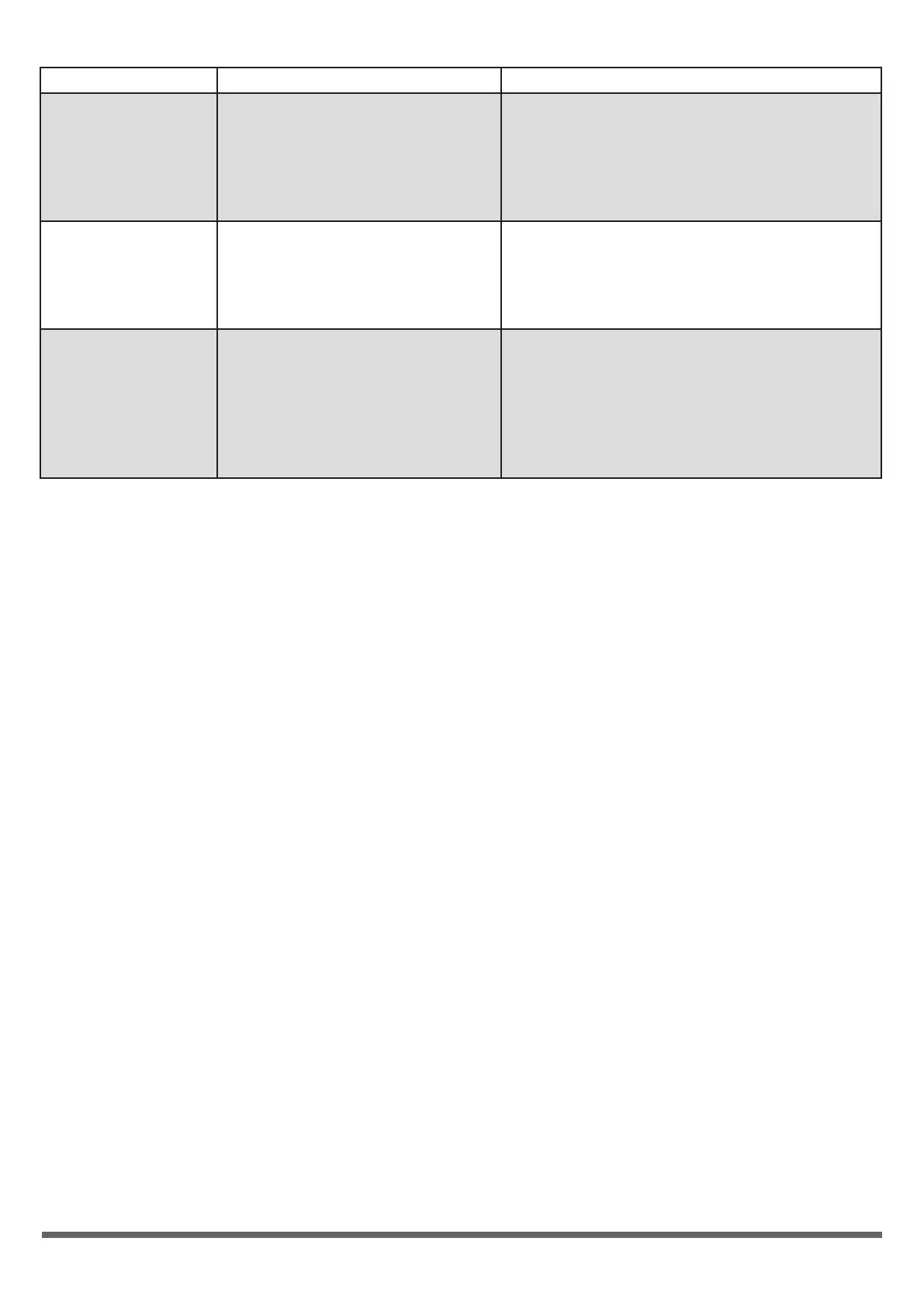

Problem(s) Possible Cause(s) Suggested Solution(s)

Overheating. 1. Poor ventilation.

2. Dirty cooling surfaces.

3. Restricted air passages.

1. Relocate compressor to an area with

cool, dry, well circulated air, at least

12 in. (30.5 cm) from nearestwall.

2. Clean all cooling surfacesthoroughly.

3. Replace transfer tubes and/

orunloaded.

Excessive

belt wear.

1. Pulley out of alignment.

2. Improper belt tension.

3. Pulley wobbles.

1. Realign pulley with

compressorflywheel.

2. Readjust.

3. Replace the pulley and check for a

damaged crankshaft or flywheel.

Compressor

won’t start in

cold temperatures.

1. Too much back pressure

in tank.

2. 40W oil in crankcase.

3. Compressor too cold.

1. Open drain valve when

startingmotor.

2. Use synthetic, non-detergent

air compressor oil suitable for

lowtemperatures.

3. Move compressor to a

warmerlocation.

Loading...

Loading...