Auto Bailers

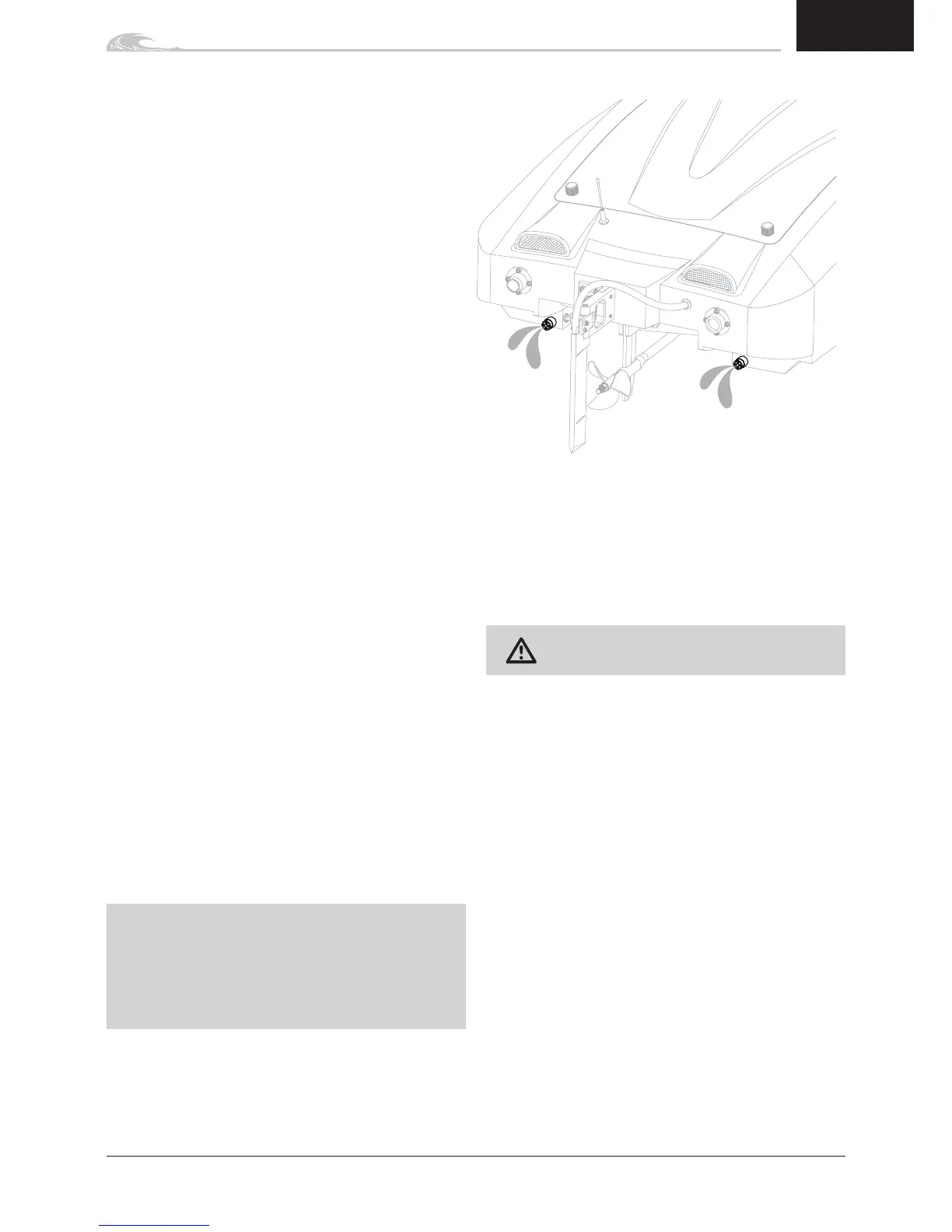

Yourboatisequippedwithtwoautobailers.Eachauto

bailerworksasamechanicalone-wayvalve.

Insidetheautobailerisaballbearingandarubberseal.

Theballbearingisfreetomovewhenthebailerisnotin

contactwithwater,allowingwatertoexitthehull.

Oncesubmerged,thepressurefromthewaterpresses

theballbearingagainsttherubberseal,preventingwater

fromenteringthehull.

1. Keeptheinsideofthehullcleanandfreeofdebristo

ensuretheautobailerswillworkproperly.

2. Whenyouapplythrottleandtheboatisonplane,the

autobailersareoutofthewater.Theboat’sforward

momentumdrivestheballbearingback,openingthe

valveandallowingthewaterinsidethetheboatto

exitthehull.

3. Onceyouremovetheboatfromfromthewater,tip

thenoseoftheboatupwardsandwaterinthehull

willrunfromtheautobailers.

Testing and Servicing

Undernormaluse,itisnotnecessarytoservicethe

autobailersoftenbecausetherearenowearableparts.

However,ifyourunyourboatinsaltwaterorinwater

withhighchemicalcontent,itmaybenecessaryto

inspectthecomponentsinsidetheautobailersforwear.

PRB286043hasthenecessarypartstoreplaceworn

partsorreplacetheautobailerscompletely.

1. Carefullyunscrewtheendoftheautobailer,taking

carenottodropthealuminumballbearinginsidethe

autobailerasyouremovethecover.

2. Removetheballbearingandinspectitforpitting.If

theballbearingdoesn’tlookwornorpitted,youcan

reuseit.

3. CarefullyremovetheO-ringfrominsidethebailer

housing.UsetweezerstoremovetheO-ringifyou

cannotreachitotherwise.Do not use sharp tools

to remove the O-ring or you may damage it or

tear it.

4. InspecttheO-ringforwearortears.Replaceitas

necessary.

5. Ifthepartsarenotworn,reinstalltheminreverse

order.

NOTICE: DonotapplygreasetotheautobailerO-ring.

Doingsocouldpreventtheballbearingfrommoving

freelyinsidethebailerhousing.

NOTICE: Donotusethreadlockingfluidontheauto

bailerhousingcover.Doingsowillpreventyoufrom

laterservicingthebailerandcoulddamagethebailer.

Replacement

1. Useasolderingirontoapplyheattotheautobailer.

Placethesolderingirononthemiddleringoftheauto

bailerwhileholdingthebailerwithapairofpliers.

2. Asthebailerheatsup,lightlyapplybackandforth

lateralpressuretothebailer.Thebindbetweenthe

bailerandtheepoxywillweaken.

CAUTION:Applyingtoomuchforceortoo

muchheatcandamagethehull.

3. Oncetheautobailerisfree,setitasidetocooland

disposeofitaccordingly.

4. Disassembleyournewautobailerandsettheball

bearingandO-ringinasafelocation.Useanailfile

ormediumemeryclothtoremovethesmoothfinish

aroundtheneckofthebailer.Theneckofthebailer

insertsintothehull.

5. ApplyaminimalamountofmediumCA(DYNK0030)

aroundtheneckoftheautobailer.

6. Oncethebailerhasbeeninsertedandglued,we

recommendaddingCAtothebailerfrominsidethe

hull.TakecarenottorunCAintothebailerhousing.

Ifitrunsintothebailerhousing,useacottonswab

lightlysoakedinacetonetoremoveexcessglue.

7. AllowtheCAtodryovernight.Onceitisdry,

assemblethebailerbyinstallingtheO-ring,ball

bearing,andbailercap.

5

Loading...

Loading...