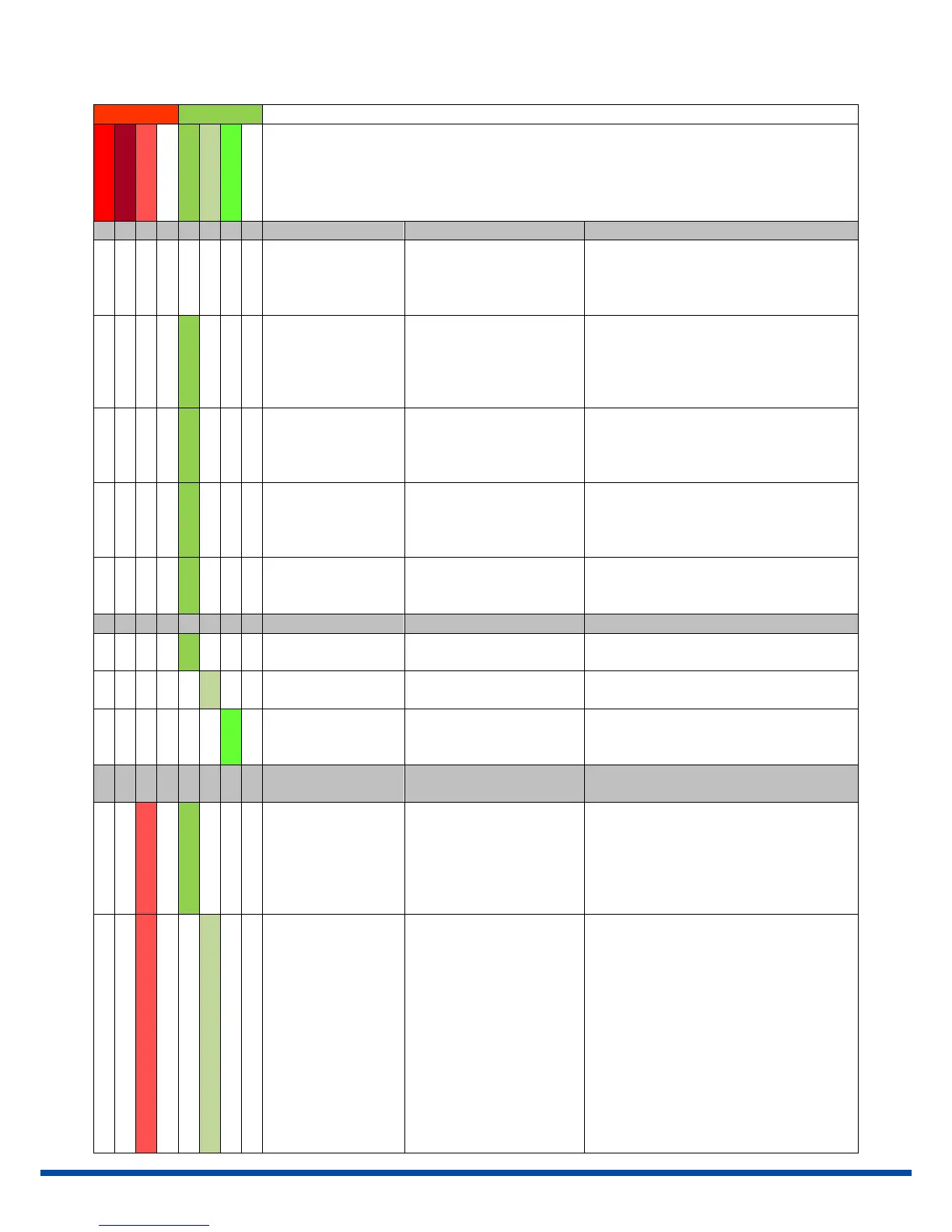

Actuator does not

respond, both LEDs are

off

1) No supply voltage applied

2) The applied voltage does not

match the actuator voltage on

the tag plate

1) Check mains supply

2) Apply correct supply voltage

Actuator does not drive

the full stroke

1) Actuator not correctly

commissioned

2) Too small stroke

programmed (in mode “one

position-dependent cut-off”)

1) Repeat commissioning

2) Check valve stroke parameters -> see

instructions AMS-PSCS

Actuator does not close

the valve properly

1) Actuator not correctly

commissioned

2) Actuator closing force/

torque too low

1) Repeat commissioning

2) Check actuator selection

Actuator is in normal

operating condition, but

does not respond to set-

value changes

1) Fixed digital set-value is

activated

2) Actuator is configured to

work with process controller

1) Check set-value parameters -> see instrucions

AMS-PSCS

2) Connect process sensor

Actuator position does

not correspond to set-

value input

A non-linear valve curve has

been parameterised

Verify parameterised characteristic -> see

instructions AMS-PSCS

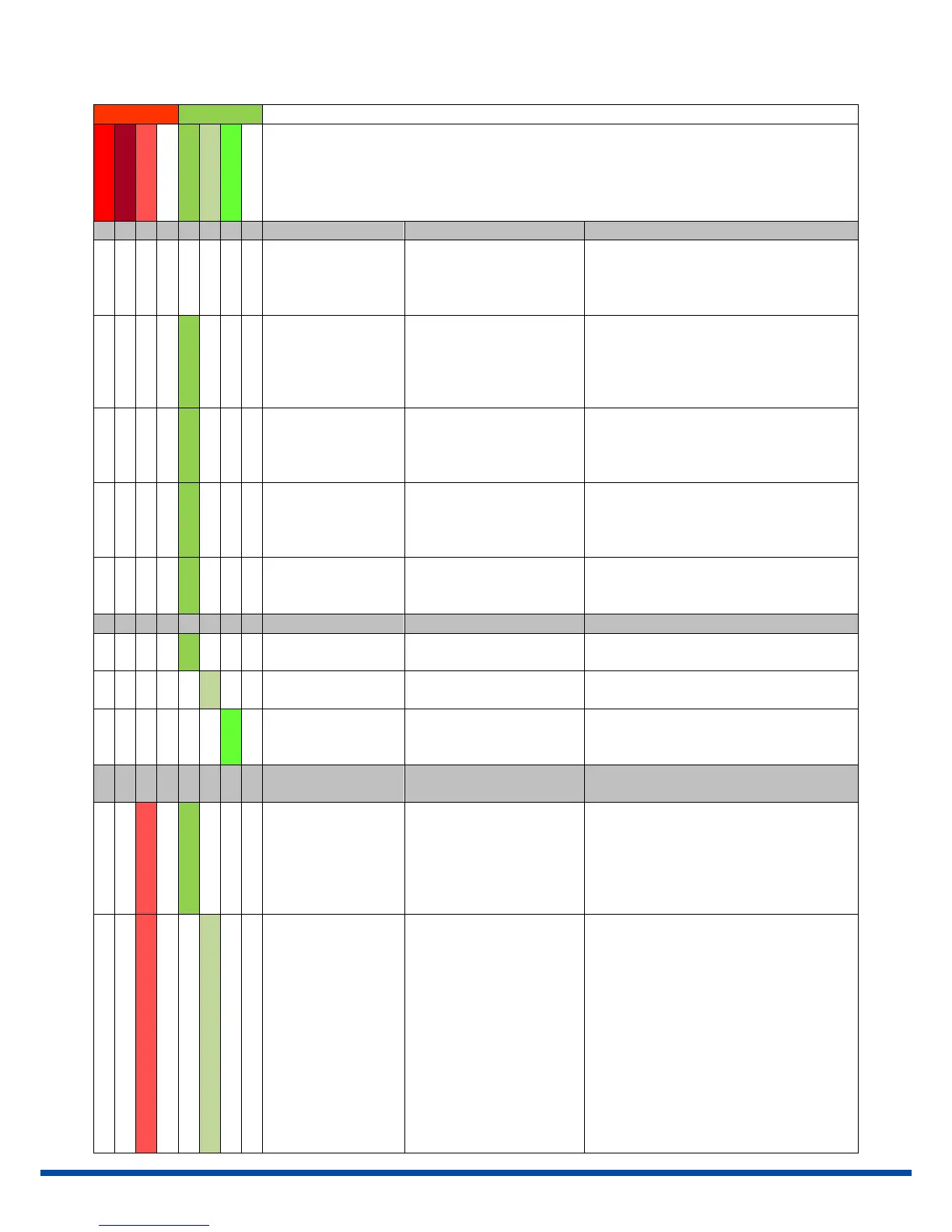

Normal operating

condition

Actuator in

commissioning mode

Commissioning mode will be left automatically

after completion

Actuator not

commissioned

Depending on the type of cut-offs, the actuator

has to be commissioned either automatically or

manually

Faults within the

actuator’s environment

Too high torque has

been encountered

within the valve stroke

1) Actuator not correctly

commissioned to the valve

2) Mechanical block within the

stroke path

3) Improper selection of the

actuator

1) Repeat commissioning

2) Check valve and actuator for unobstructed

running

3) Check actuator selection

1) No proper process

feedback (only in

combination with PSIC)

2+3) Maximum control

range exceeds (only in

combination with PSIC)

1) Process feedback wrongly or

not at all connected

2) Process feedback outside od

adjusted range

1) Apply the correct process feedback signal and

check polarity

2) Ensure the correct process feedback range

3) Check the process sensor and its supply

voltage

Loading...

Loading...