7

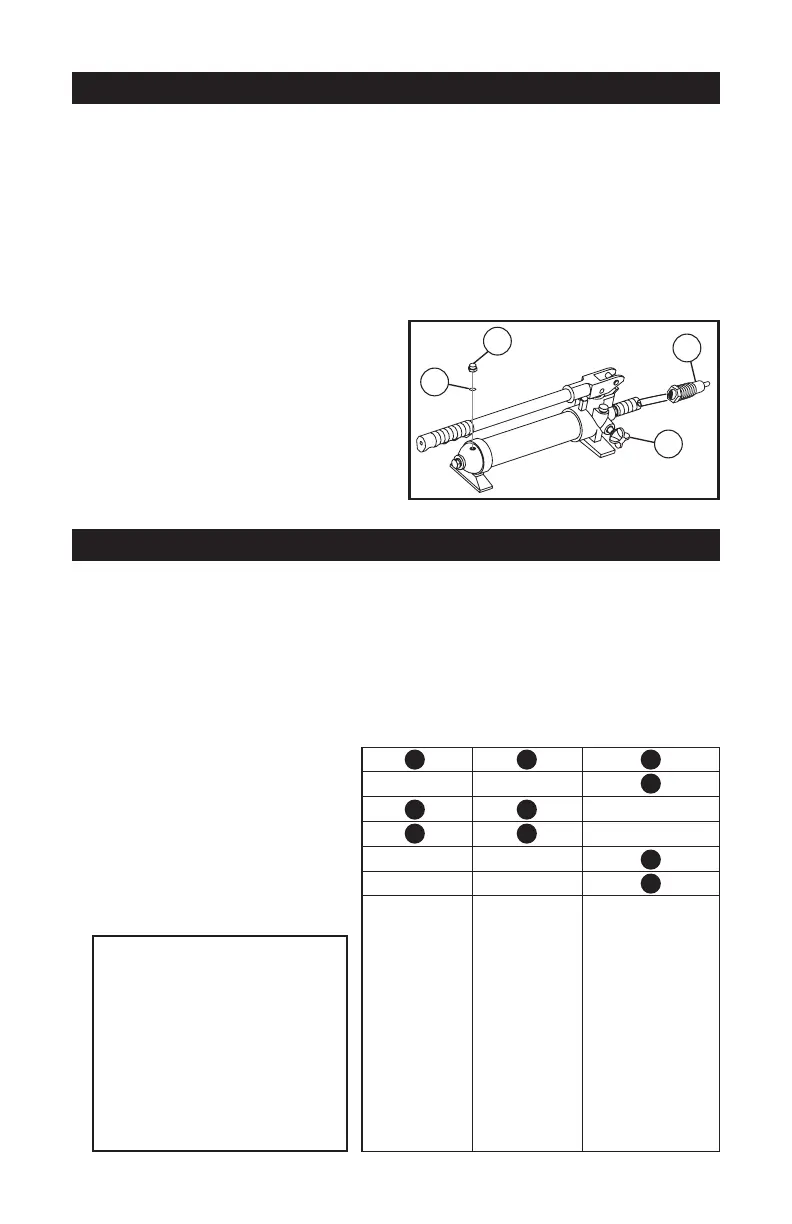

7. Change the hydraulic oil at least

once every three years:

a.

Set Pump (1) at on a level surface.

b.

Remove the Fill Screw (A). The

O-ring (B) should come off with it.

c. Tip the pump to allow the old

hydraulic oil to drain out of

the housing completely, and

dispose of the old hydraulic

oil in accordance with local

regulations.

d. With the Pump upright,

completely ll the housing with

a high quality hydraulic oil (not

included) until the oil just begins

to run out of the oil ll hole. Be

VERY CAREFUL not to allow dirt

or foreign matter into the system.

CARE & MAINTENANCE

A

B

C

D

Fig. 5

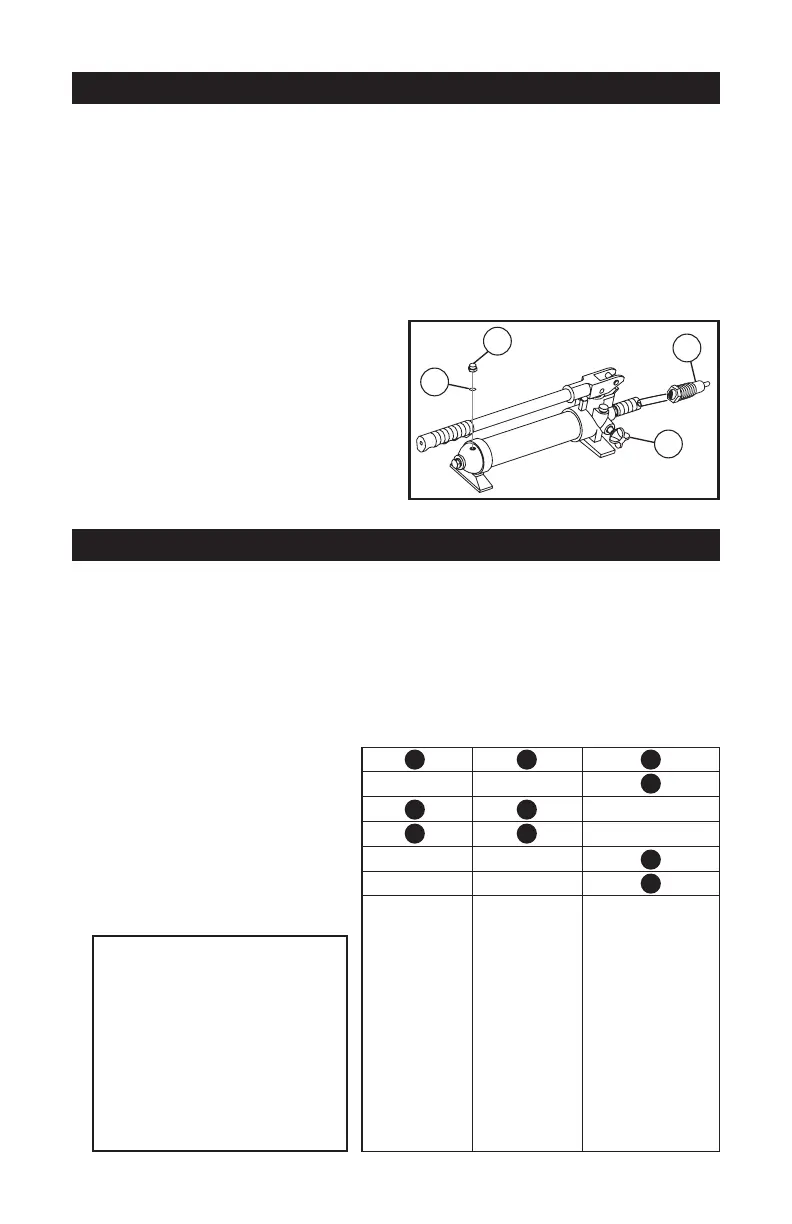

NOTE: Problems listed above

with more than one solution

may have a combination of

causes. Please be sure that

all solutions listed for each

problem have been checked

to eliminate possibility of

further trouble. Sometimes

solutions may need to be

repeated for best results.

TROUBLESHOOTING

This Performance Tool

®

product was constructed with quality materials and

workmanship and will give you many years of trouble free use when cared for

as described in the "Care & Maintenance" section on page 6-7. However, as

with any mechanical device, periodic adjustments are necessary to maintain a

peak level of performance. Should this product be displaying any of the following

symptoms, the simple procedures shown below will correct the problem.

WARNING: Remove all equipment from service before making adjustments.

Will not lift load

Will not hold load

Will not lift to full height

Pump feels “spongy” under load

Handle raises under load

Handle lowers under load

Power unit may

be low in fluid.

With pump on

level surface and

in down position,

remove filler

plug and add

clean hydraulic

jack fluid to level

of filler.

Power unit may

be air bound.

Open the

release valve a

minimum of 2 full

turns. Pump the

handle a

minimum of 20

full strokes to

purge air from

the system.

Valve may not be

closing completely.

To seat valves:

a.) Close release

valve.

b.) With pump in fully

lowered position,

manually raise

lifting arm as

high as possible.

c.) Open release

valve and allow

pump to descend

to lowered position

e. Make sure the O-ring (B) is still

in place around the Fill Screw

(A) and thread the Fill Screw into

the Pump securely. Do not use

thread seal tape.

f. Firmly close the Release Valve

(C) by turning it clockwise.

g. Clean with a clean cloth using a

detergent or mild solvent.

Loading...

Loading...