11984 Rev 01 Page 4 of 8

1.3 Requirements

4. A “carrier” supply to ensure there is enough flow to provide control, even in the

presence of very low gas flow (for example, during steam processes where

much of the process effluent is condensed prior to the controller)

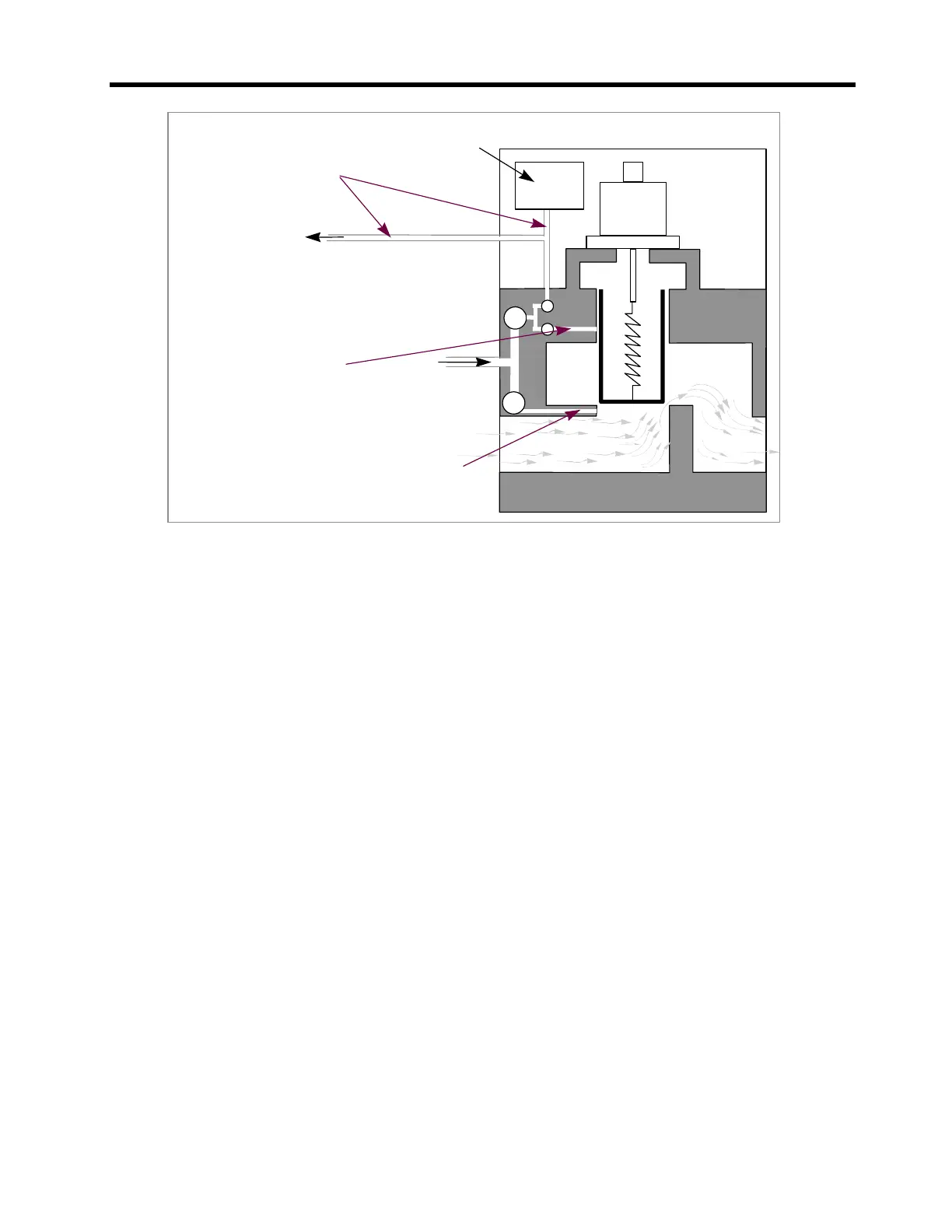

Figure 1-2 shows how the nitrogen is distributed to perform these functions.

Sufficient nitrogen is critical to optimum operation. Without sufficient nitrogen, the

transducer can be damaged and contaminants may back stream from house

exhaust. In addition, if process flow rates drop significantly, the controller

performance may be degraded.

House Exhaust Requirements

Minimum house exhaust requirements are given in Appendix B. However, in many

installations, less house exhaust is required, and in some specific installatios,

additional house exhaust is required. This section allows the user to calculate the

amount of exhaust required for a specific installation.

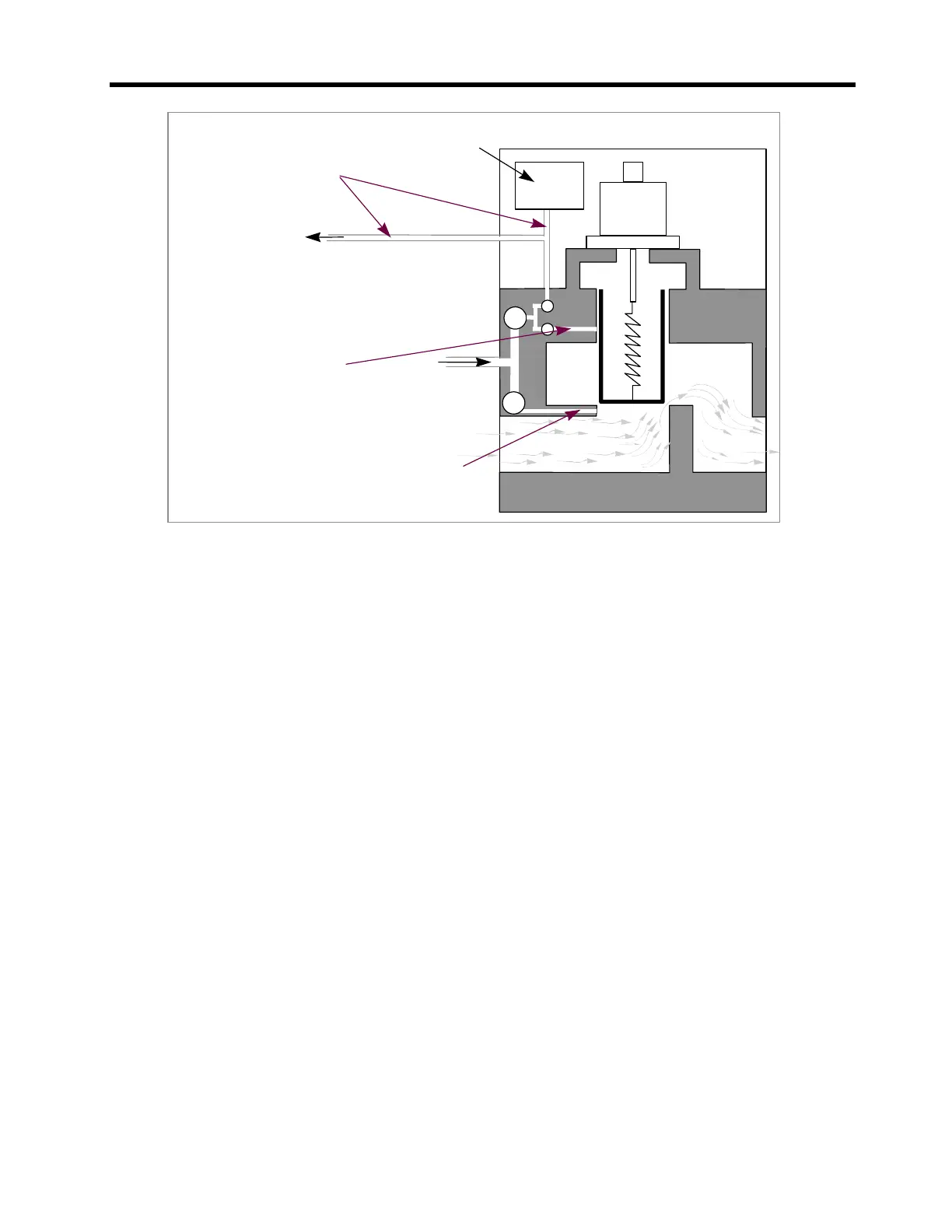

Calculating minimum house exhaust requirements to operate a “sealed” vertical

furnace at a specified Process Pressure is a relatively simple process; however,

careful attention must be paid to the exhaust path configuration when doing this

calculation. Figure 1-3 is intended to be a guide to assist the user in making this

calculation. This calculation consists of the basic formula:

P

Sense

- (P

Exit

+ P

Controller

+ P

Facility

) = Minimum House Exhaust Requirement

where;

P

Sense

= Process Pressure or Set-Point within the Sealed Chamber.

2

Nitrogen

Bearing

Purge

(to process tube)

Figure 1-2: Nitrogen is used in three different places in the SENTRY 1510.

Loading...

Loading...