Operation & Installation Manual

SENTRY™ 1510

Section 6: Troubleshooting

11984 Rev 01 Page 1 of 5

6.1 Troubleshooting

VER 2.9

N

2

at 30-100

psi

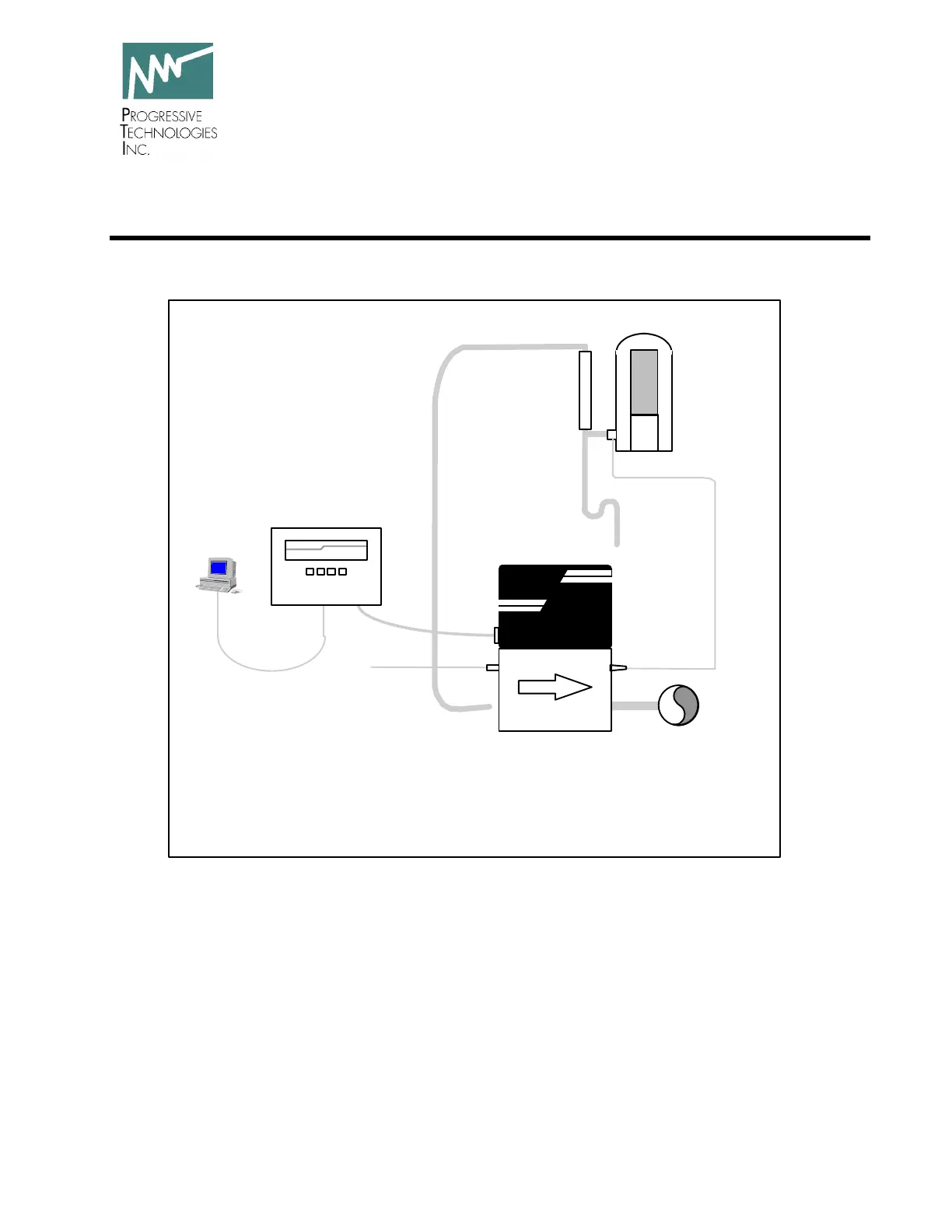

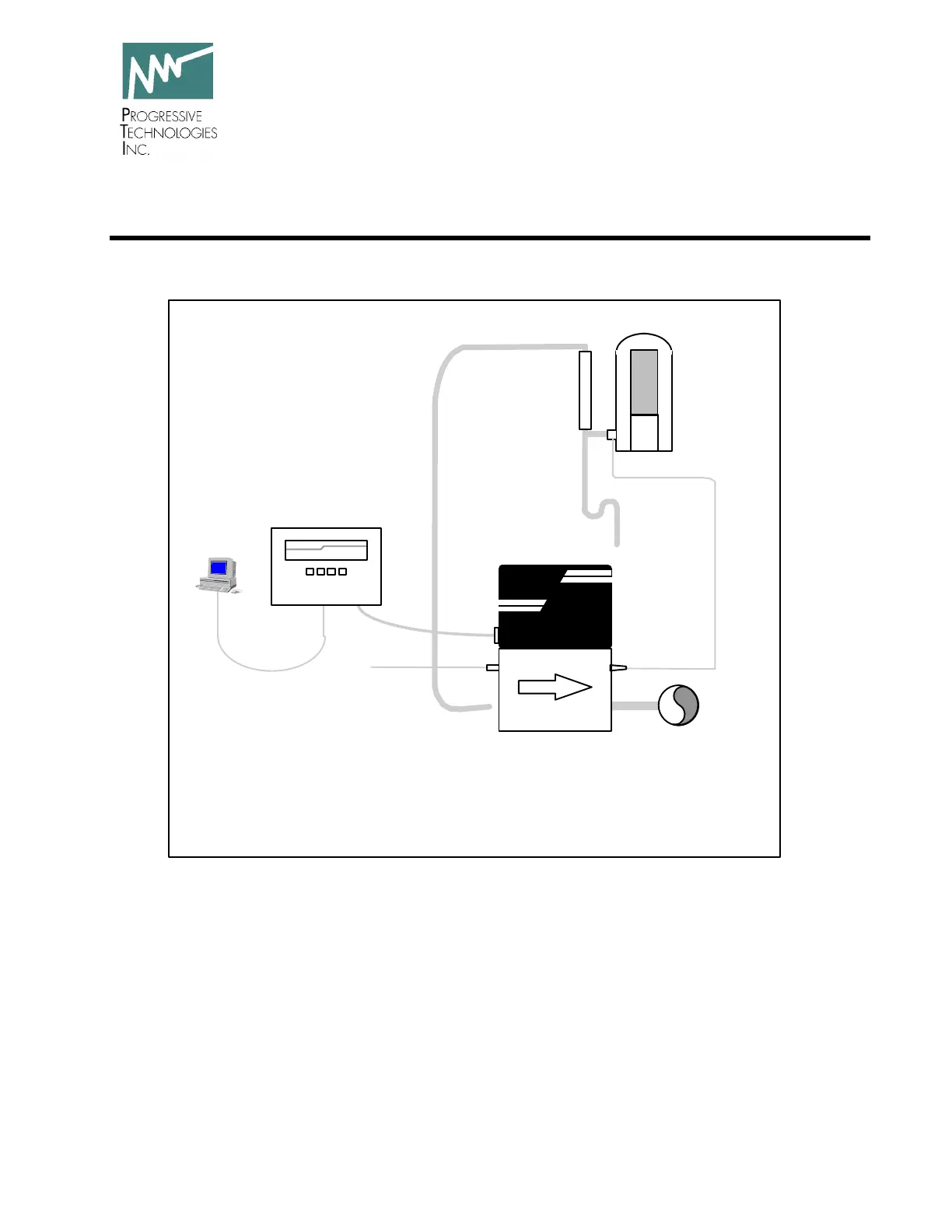

1. Process tube to intake (with drain)

2. Outlet to house exhaust (at least -2

inches H

2

O static pressure)

3. Supervisor to SENTRY cable

4. Tube controller to Supervisor cable

5. Pressure sense line from SENTRY

barbed fitting to process tube

6. Nitrogen to Swagelok fitting on

SENTRY

7. Supervisor power on

1

2

3

4

6

7

X

To drain

5

SENTRY™ 1510

Figure 6-1 : Check for the most common causes first.

Troubleshooting

Several basic causes are the source of most problems seen with the SENTRY 1510.

It will save time if these causes are checked first. Check items 1-7 in Figure 6-1

before continuing with the troubleshooting guide.

Loading...

Loading...