Operation & Installation Manual

SENTRY™ 1510

Section 2: Functional Description & Operation

11984 Rev 01 Page 1 of 2

2.1 Functional Description

Functional Components

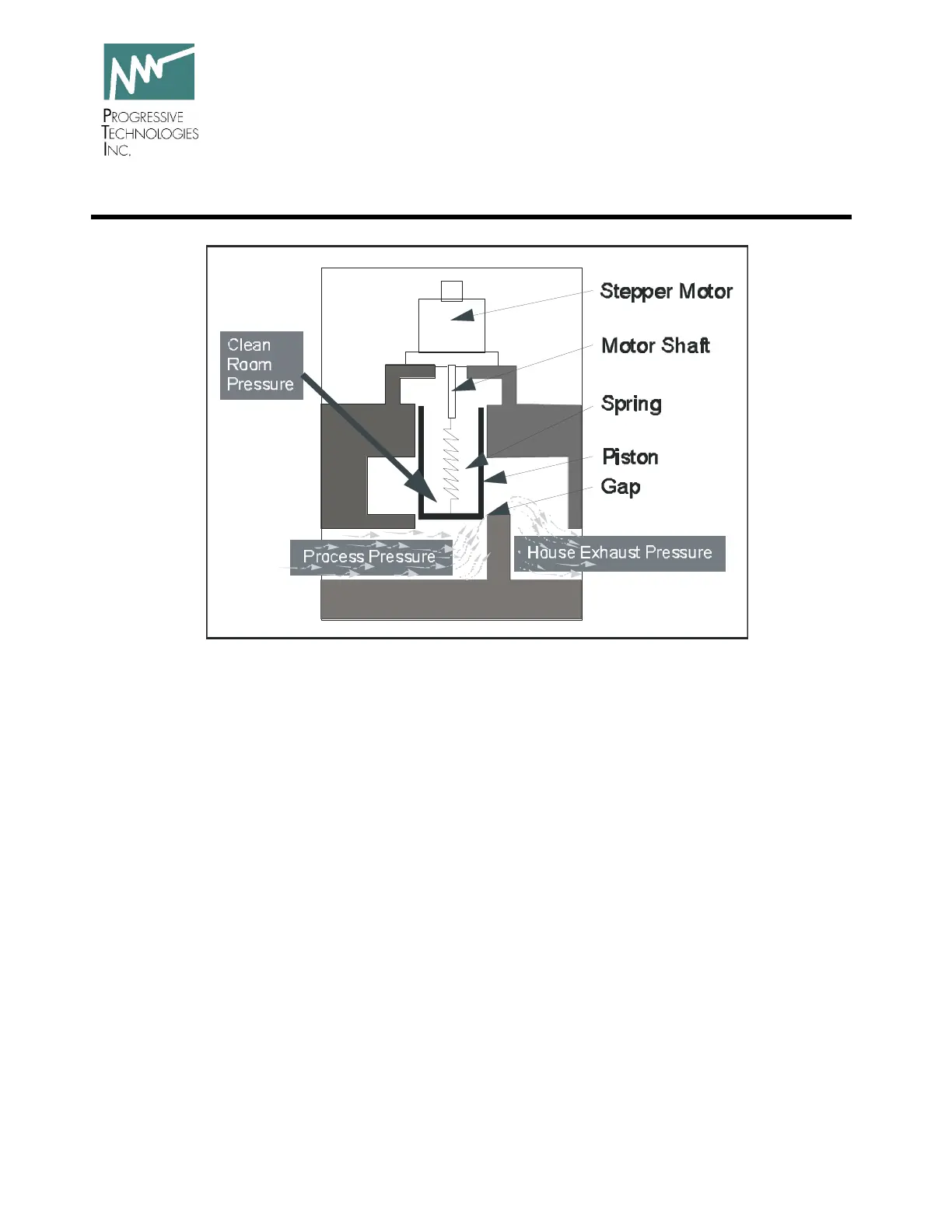

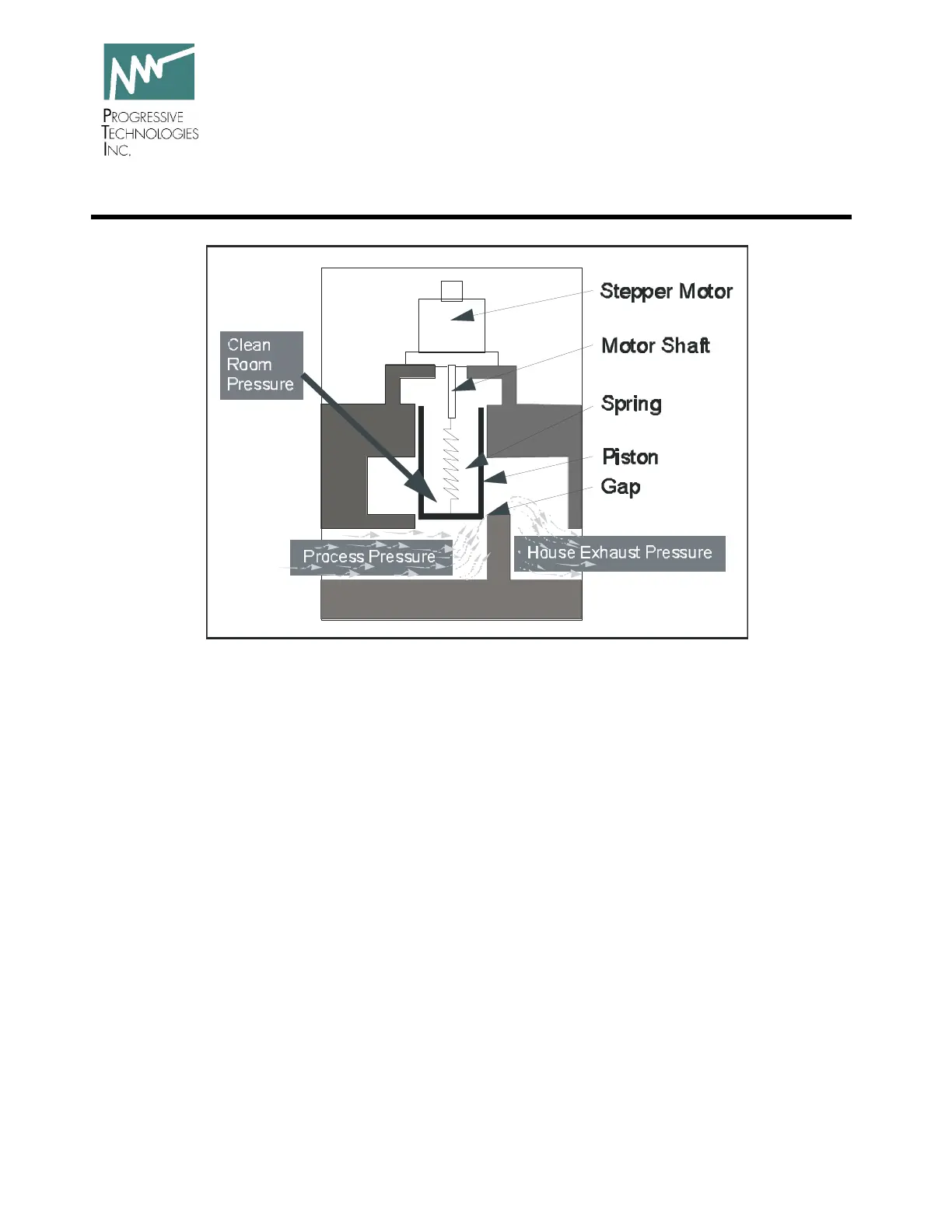

The SENTRY 1510 is an automated pressure controller. It consists of a piston on a

spring, differential pressure transducer and a stepper motor. The interface

between the operator or the diffusion furnace and the SENTRY 1510 is the

Supervisor.

Piston

The piston provides the active control for the SENTRY 1510. It is suspended by a

spring and mechanically regulates exhaust pressure to a constant value. (For more

information on how the piston controls, see section 1, page 2.)

Differential Pressure Transducer

The differential pressure transducer is mounted on the SENTRY 1510 body and

measures the pressure differential between the clean room and the process tube.

Stepper Motor

The stepper motor is attached to the spring which suspends the piston. By moving

the stepper motor, the spring tension is changed, changing the pressure to which

the piston regulates. In other words, the stepper motor changes the set point.

Supervisor

The SENTRY Supervisor is separate from the SENTRY 1510 and provides an

interface between the operator or diffusion furnace controller, and the SENTRY

1510. The SENTRY Supervisor may be programmed manually, through the keypad,

through an RS422/485 interface or through an analog interface.

Loading...

Loading...