11984 Rev 01 Page 7 of 8

1.3 Requirements

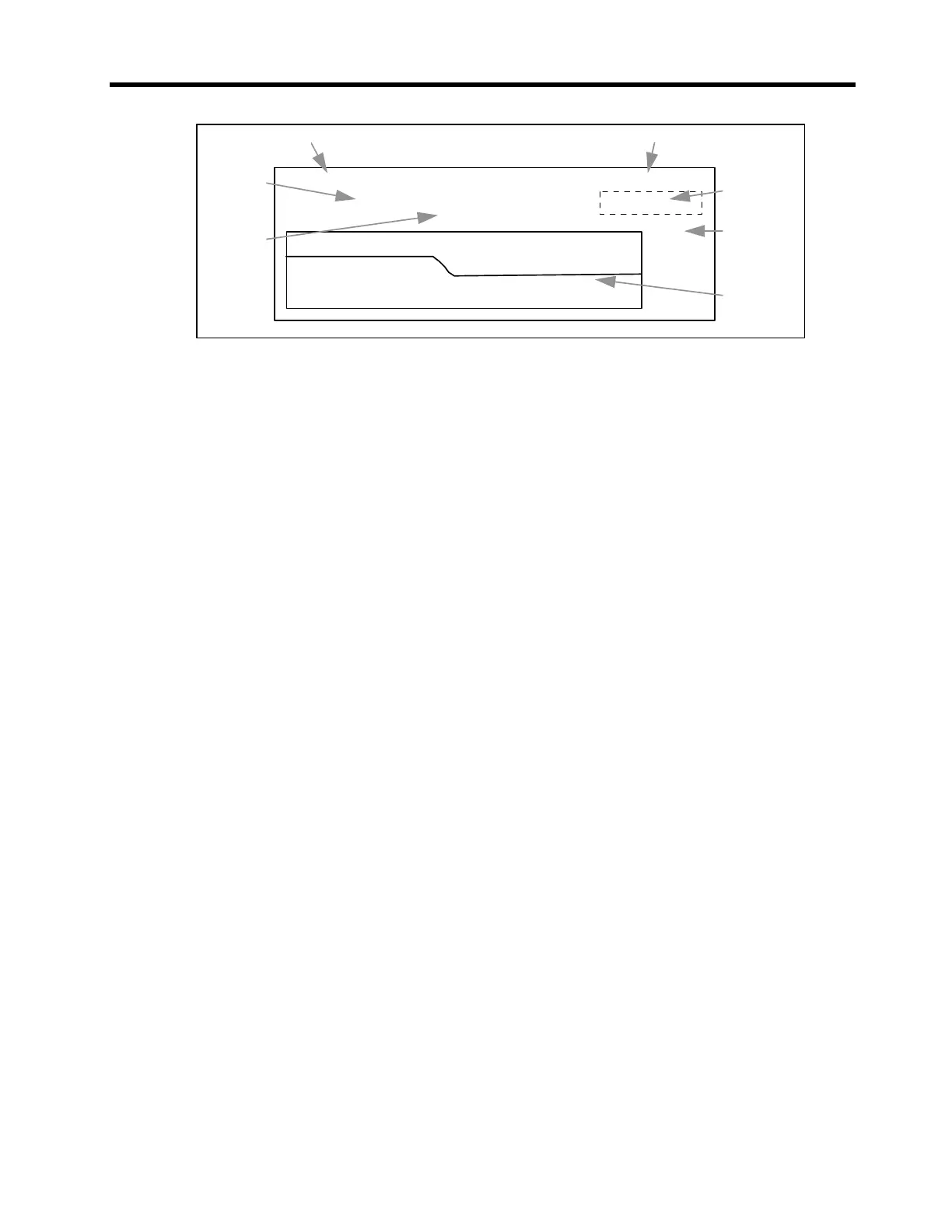

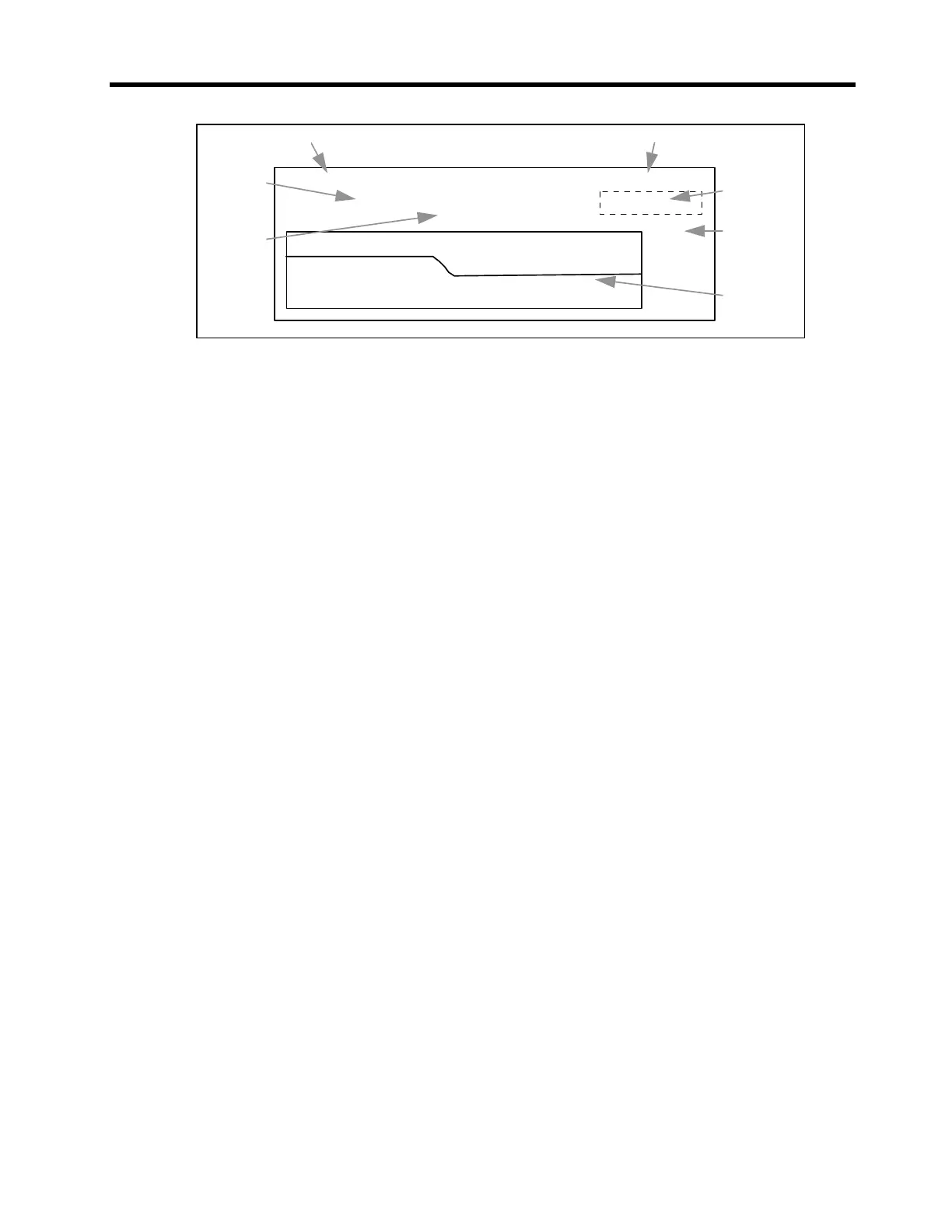

Sentry Ver G1.9

SUN 00:00:00

Pres S 1700 Pres 1700

FLOW

2000

0

Software version Day - Time

Alarm

Display

Full Scale

2.000"

Real time

trend

Setpoint

Measured

pressure

Figure 1-4: The Supervisor LCD Display gives the user a “window on to the

process.”

The Supervisor acts as the interface and display between the user and the

SENTRY 1510. The Supervisor has a graphic display screen that provides the

operator information about the SENTRY and the process. This includes the set

point, measured process exhaust pressure, alarm status and the date and time

(see Figure 1-4). The pressure information is displayed in real time and in

graphical form. A 4-key interface allows the operator to control the SENTRY 1510

in local mode. In local mode, the operator can key in set point changes and modify

control parameters. For more information on the Supervisor, refer to the “SENTRY

Supervisor Operation Manual and Serial Communications Programmer’s Guide”.

There are two options for supplying power to the Supervisor: from the “host” or

stand alone.

1. In the stand-alone configuration, the Supervisor is fitted with a power adapter

cable. The adapter cable includes a standard AC wall plug and power supply

that generates two DC operating voltages. (NOTE: Power supplies are avail-

able for several AC voltages. Check the voltage marked on the cable for

compatibility with your installation.) The interface cable mates the power

supply to the Supervisor.

2. The second option allows power to be supplied directly from the process tool

controller eliminating the need for an AC supply. In this case, the host interface

cable carries positive and negative DC power to the Supervisor. The DC

requirements are:

+ 15 to 24 VDC at 500 mA

-15 to -24 VDC at 50 mA

There are two options for communications with a host (typically the process tool

controller): “serial” and “analog”

Loading...

Loading...