QuickJack™ Portable Car Jack 48 P/N 5900263 — Rev. B6 —September 2023

Maintenance

Refer to ANSI/ALI ALIS Standard (current edition) Safety Requirements for Installation and Service of

Automotive Lifts for more information about safely servicing your QuickJack.

⚠ DANGER Before performing any maintenance to your QuickJack, verify it is completely

disconnected from power. If your organization has Lockout/Tagout policies, make

sure to implement those procedures after connecting to the power source.

Replace labels and worn, damaged, or broken parts from quickjack.com/replacement-parts.

Only use factory-supplied parts as replacement parts. All maintenance tasks can be performed by the

owner/operator of the QuickJack.

To maintain your QuickJack:

• Daily. Make a visual inspection of all moving parts and check for damage or excessive wear.

Replace any damaged or worn parts before equipment is put back into operation.

• Daily. Keep all QuickJack components clean.

• Daily. Make sure the Safety Locks are in good operating condition. Do not use your QuickJack if

the Safety Locks are damaged or excessively worn.

• Daily. Inspect Lift Blocks for damage or excessive wear. Replace as required.

• Daily. Inspect Quick-Connect Fittings. See Quick-Connect Fittings Maintenance and Best

Practices below.

• Weekly. Check all hose and fitting connections to make sure they are tight.

• Monthly. Lubricate all hinge points and check for excessive wear.

• Monthly. Cycle the Frames up and down several times with weight at least once a month. This

will help maintain the cylinder seals’ elasticity.

• Every other month. Check Hydraulic Fluid levels and refill if required.

• When required. Replace all caution, warning, and safety-related labels if illegible or missing.

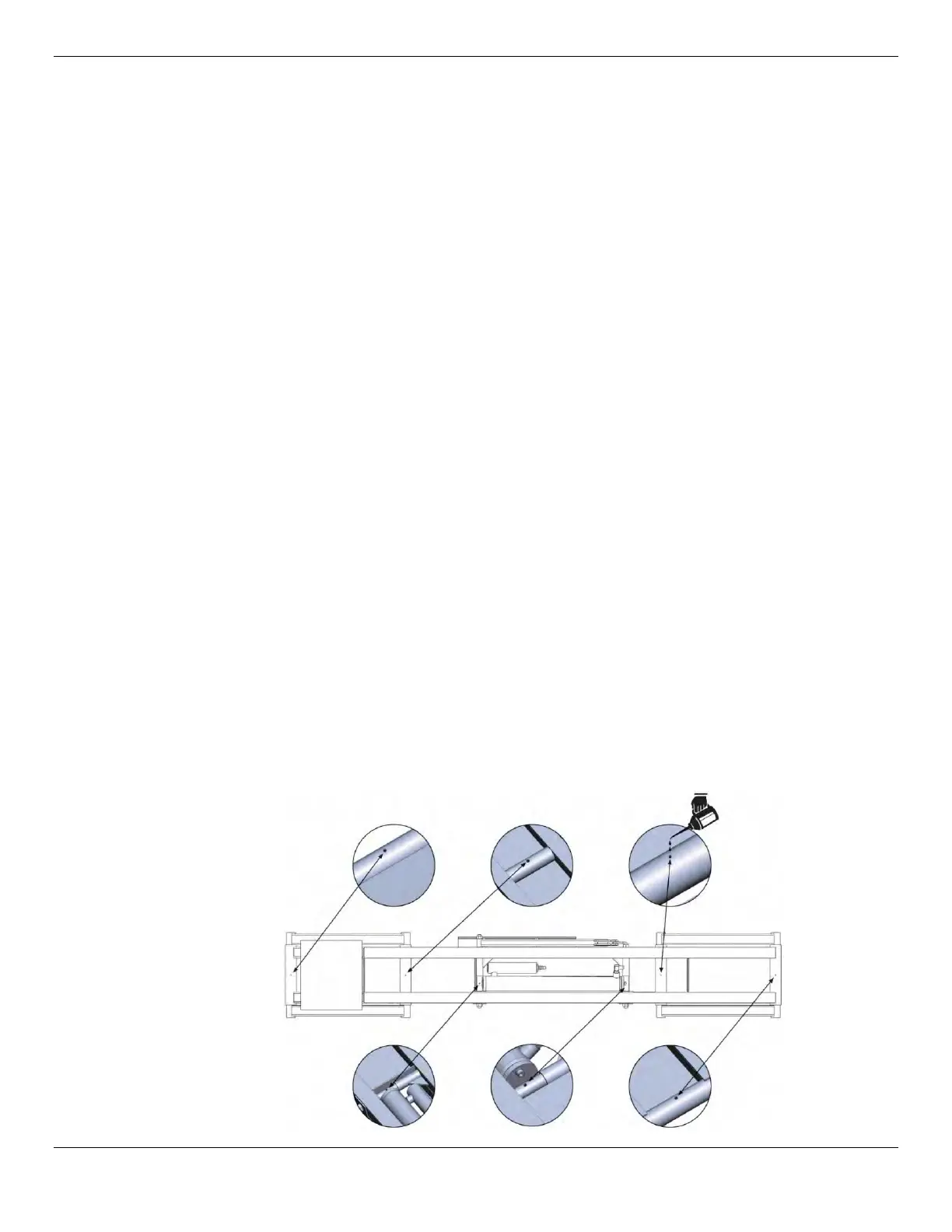

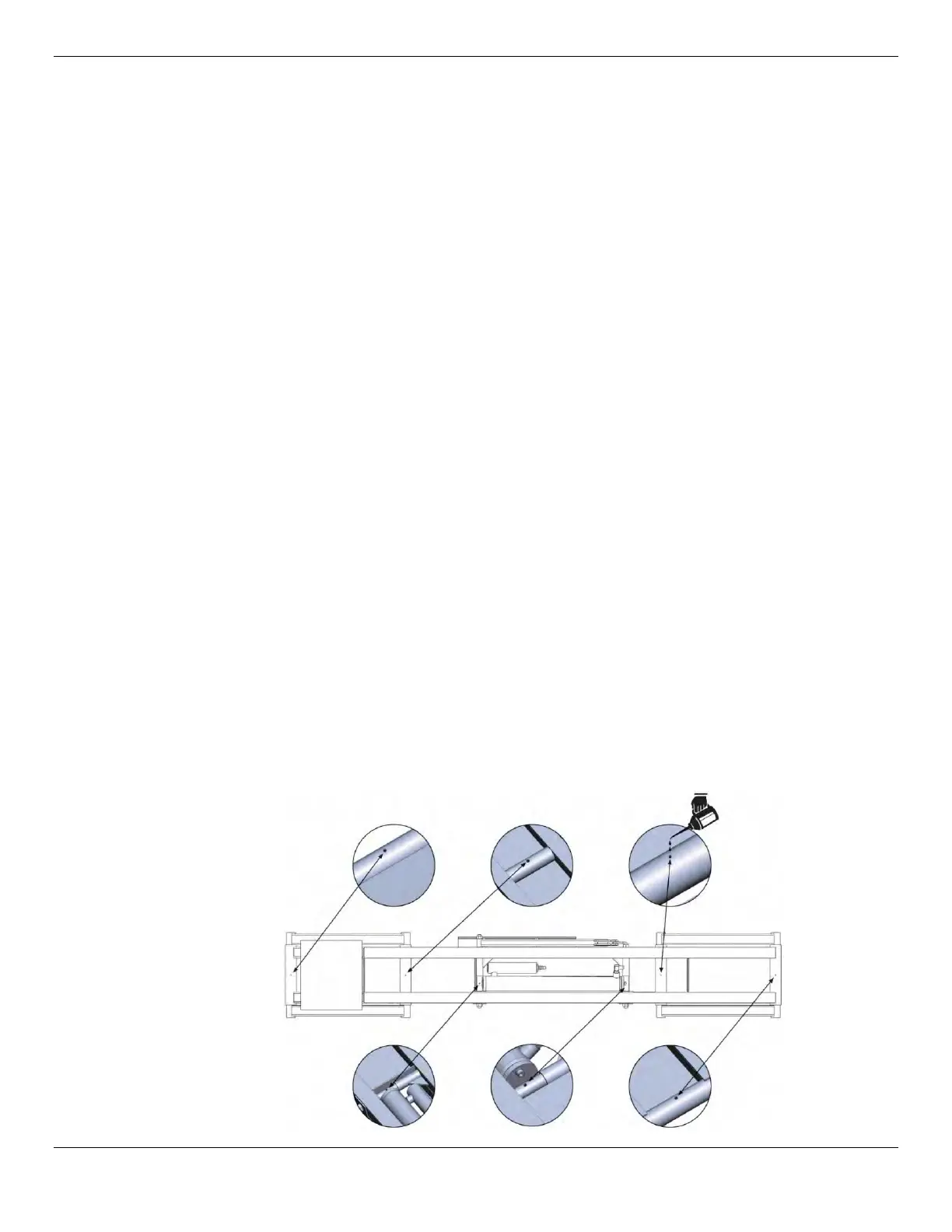

Lubrication Points

QuickJack recommends using white lithium grease (or equivalent) and a grease gun with an

appropriate tip (a Lube-Link™ or similar) for lubrication. Apply to both Frames, lubrication points are

indicated below.

Loading...

Loading...