QuickJack™ Portable Car Jack 51 P/N 5900263 — Rev. B6 —September 2023

Troubleshooting

This section describes how to troubleshoot your QuickJack. Qualified personnel must accomplish all

repair work.

⚠ WARNING Only use factory-supplied parts as replacement parts. If you use parts

from a different source, you void your warranty and compromise the safety of

everyone who uses the QuickJack.

Note: If your QuickJack is not functioning correctly, you must stop using it until it is fixed.

If you continue to have an issue, visit quickjack.com/support or contact QuickJack Support at

support@quickjack.com, (888) 262-3880, or (805) 933-9970.

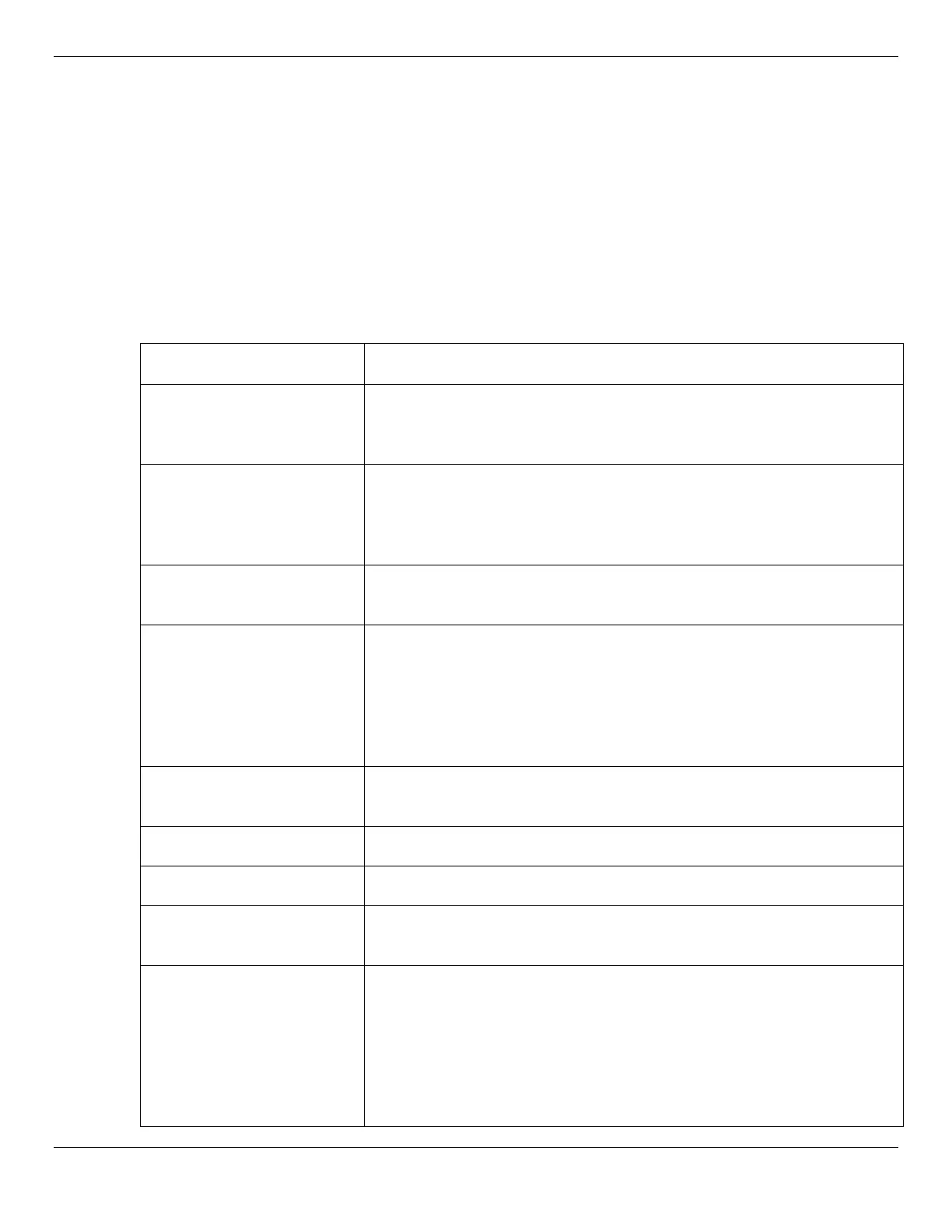

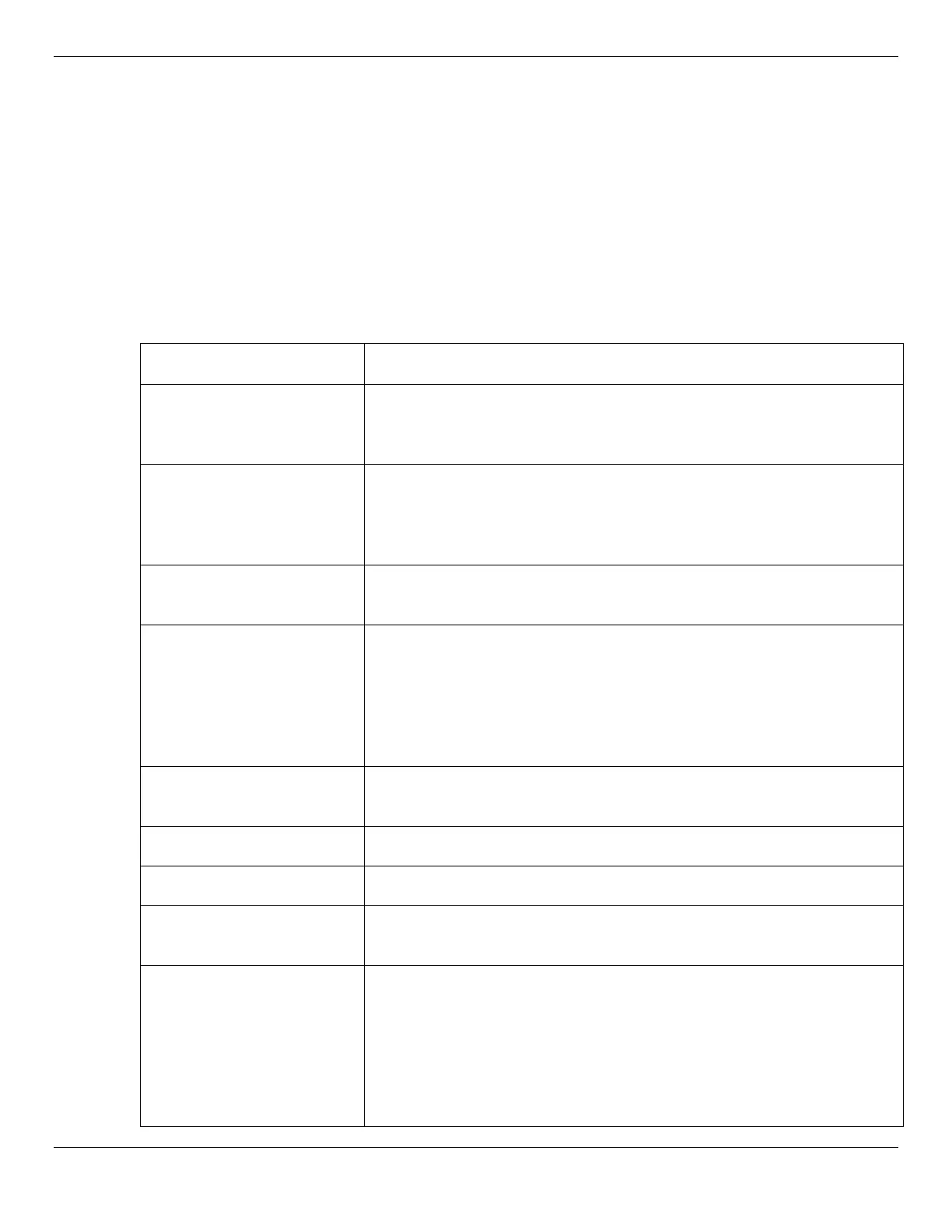

Issue Action to Take

Frames do not go up or

down.

Verify the Power Unit is getting power; if not, check the circuit breaker.

Verify none of the Hydraulic Hoses are pinched or leaking. Verify there

is sufficient Hydraulic Fluid in the Fluid Reservoir. Bleed the cylinders.

Frames do not come down. Make sure there is a Vehicle on the Frames

; if not, add one

(the QuickJack is designed to work with weight). Check the pressure in

the

Auxiliary Pneumatic Springs

; inflate to 40 to 50 psi, but do not

exceed 50 psi.

Frames are stuck at full

height with no weight.

QuickJack Frames require weight to come down from a fully raised

position. Refer to

Frames at Full Height with No Load

.

Frames, loaded with

Vehicle, will not lower to the

ground.

Check the pressure in the Auxiliary Pneumatic Spring; inflate to 40 to

50 psi (2.75 – 3.4 Bar), do not exceed 50 psi (3.4 Bar). Verify power is

being supplied to the QuickJack. Verify the down Solenoid Valve is

functioning. If this does not correct the issue, contact QuickJack

Technical Support at support@quickjack.com, or call

(888) 262-3880 or (805) 933-9970.

Frames do not rise from a

zero net rise position.

QuickJack Frames cannot raise a full load from a completely flat

position. Refer to

Vehicle with No Tires Fully Lowered

.

Hydraulic Fluid is dirty. Replace the dirty Hydraulic Fluid with clean fluid.

Jack makes odd noises Lubricate hinge points using white lithium grease.

Frames lower without using

the Pendant Control.

Make sure the QuickJack is engaged on a locking position (if it is not,

the Frames will slowly lower).

Pneumatic Spring is not

holding pressure.

Spray a small amount of soapy water to locate the leak. Verify the

Schrader valve core inside the valve stem is tight. You can use a valve

tool to check. Do not overtighten the valve core. It is possible that the

seal on top of the Hydraulic Cylinder has stiffened from lack of use.

Apply a few drops of hydraulic fluid to the piston rod at the top of the

hydraulic cylinder and cycle the Lift up and down a few times. This

should return some elasticity to the seal.

Loading...

Loading...