8

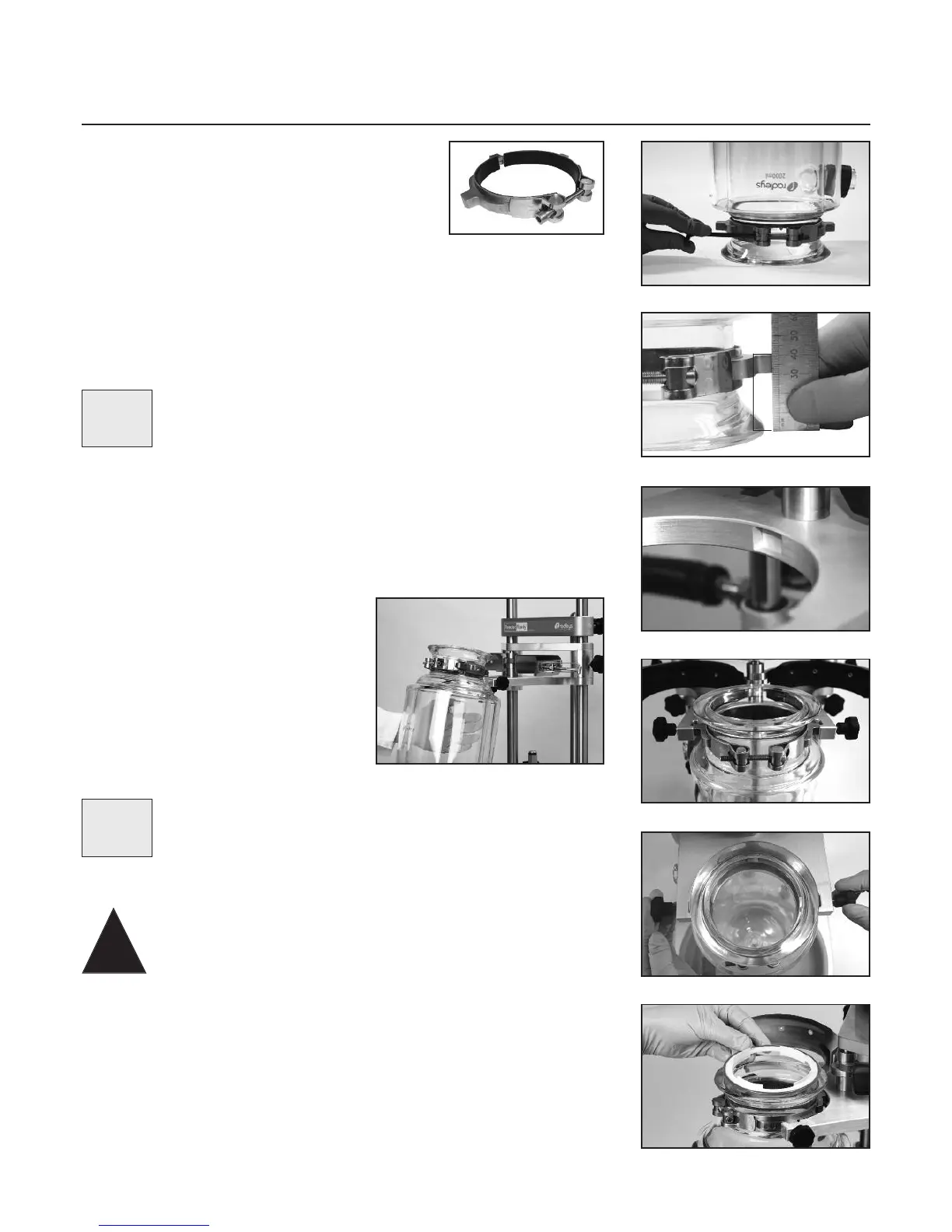

.6.2 Select the appropriate vessel for the chemistry that you

are performing. Position the Vessel Support Collar around the

neck of the vessel so that it sits immediately below the angled

section of the flange. This is best achieved by inverting the

vessel and resting it on a flat surface. Undo the bolt on the

collar and place the collar around the straight sided neck of

the vessel. With the vessel inverted, the optimum distance from the bottom of the vessel neck

to the top of the protruding lug on the collar should be between 40 and 41mm (as shown in

8.6.2). Rotate the collar so that the fastening bolt is at 90˚ to the vessel side arms (with the

inverted vessel side arms pointing to the right, the bolt should be facing you). Tighten the bolt

so that the collar closes but is still free to move vertically up and down the neck. Fully

tightening-- the bolt and the collar should self-align at the point where the angled flange

meets the straight sided neck.

8.6.3 To locate the vessel, support with two

hands, slightly tilt the vessel top away from you

and carefully locate the lug at the back of the

stainless steel Vessel Support Collar into the

central cut out in in the Vessel Support Clamp.

Then by returning the vessel to the perpendicular

plain, the two side lugs on the Vessel Support

Collar will then locate into the two rectangular

recesses on the arms of the Vessel Support

Clamp. The vessel is now fully supported.

8.6.4 It is advisable to make any adjustments to the height of the vessel on the framework at

this stage by loosening the locking nuts of the Vessel Support Clamp and sliding it up or

down. Subsequent adjustment of heights of Manifolds and Stirrer Support I-Brace may also

be necessary.

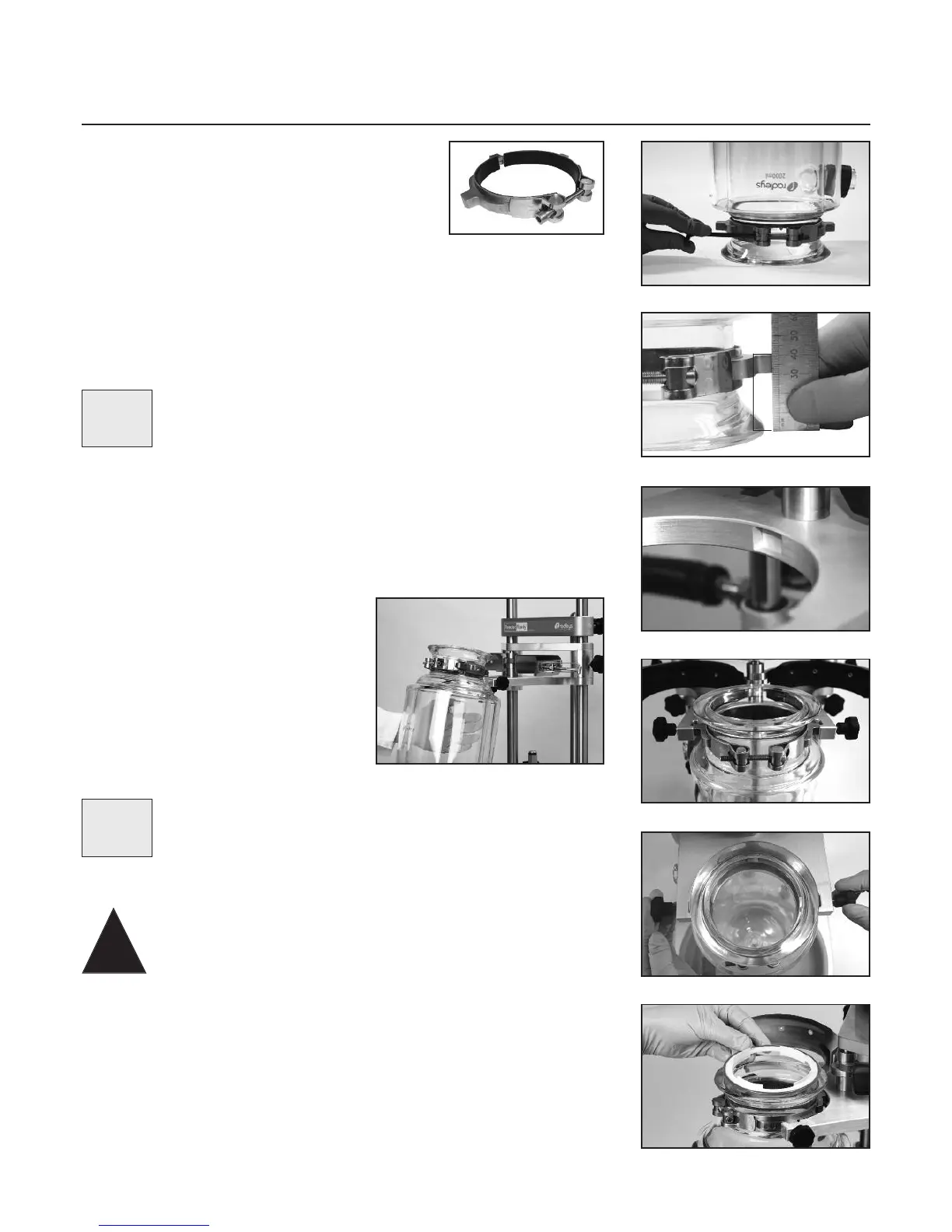

8.6.5 Assemble the Vessel O-ring Seal and PTFE O-ring Support Collar, and place the

assembly onto the vessel flange, ensuring that the retaining lip is fully located within the glass

neck of the vessel.

8. Set-Up & Operation - Continued

Reactor-Ready - Lab Reactor

Important Note - Correct positioning of the Vessel Support Collar is criti-

cal for proper alignment of the vessel when operating the clamp. If after

assembling the vessel collar, the vessel is not vertically aligned when

positioned on the clamp, it may be possible to loosen the fastening bolt on the

collar and correctly align the vessel whilst it is positioned on the clamp. Once

correctly aligned, the fastening bolt on the collar must be retightened.

Alternatively, remove and refit the vessel collar as described in 8.6.2. Use of

a measuring rule may assist in positioning the collar correctly. With the vessel

inverted, the optimum distance from the bottom of the vessel neck to the top

of the protruding lug on the collar should be between 40 and 41mm (as shown

in 8.6.2)

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important Note - When the vessel is supported on the Vessel Support

Clamp some movement of the vessel is still possible until the clamp is closed.

If required, it is possible to further secure the vessel at this stage by tighten-

ing the two smaller knobs located on either side of the clamp until they light-

ly grip the side lugs of the Vessel Support Collar.

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,

Important, Important,

8.6.3

8.6.3

8.6.3

8.6.3

8.6.5

Warning -

The screw knobs MUST be released before the final clamping

operation is performed, as the vessel must be free to move as it is clamped,

thereby ensuring a good vessel to lid seal.

!

Page 11

8.6.2

8.6.2

40mm

Loading...

Loading...