Raisecom

RC1201-2GE16E1T1 Product Description

Raisecom Technology Co., Ltd.

6.5 Check after installation

6.5.1 Checking machine room and surrounding environment

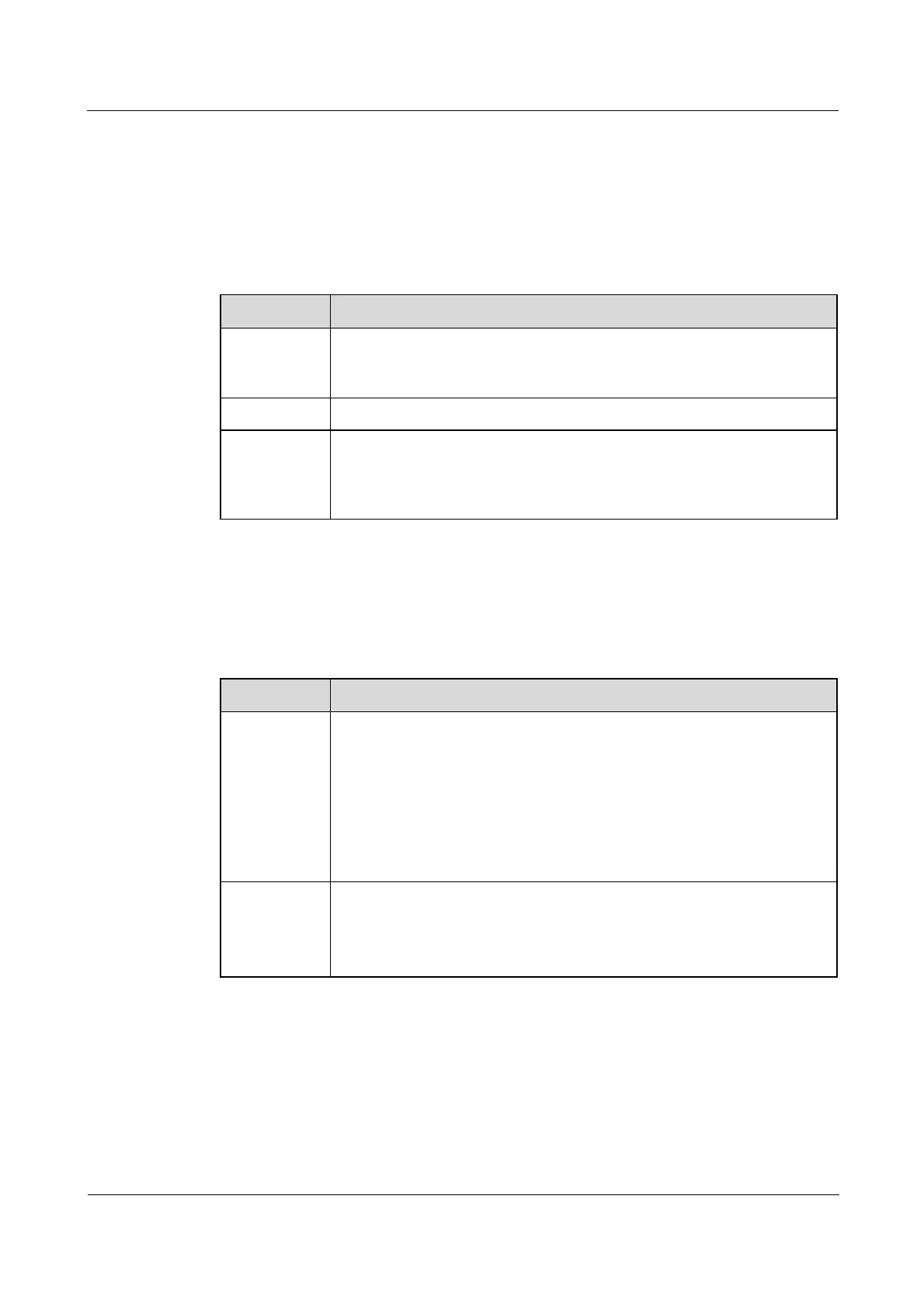

Check the machine room and surrounding environment after installation, as listed in Table 6-5.

Table 6-5 Checklist for the machine room and surrounding environment

Strap or splice the surplus cables to fix them to the reserve place inside the

rack to be expanded to facilitate the future expansion maintenance and

avoid loss.

Protect the unused plugs and cover the protection caps.

Keep clean and tidy, clear the obsolete packing boxes and other sundries.

Stack the remaining spares neatly and reasonably. The value of grounding

resistance should be smaller than 1 Ω, and at the same time refer to the

relevant national or local standards.

6.5.2 Checking chassis or workbench

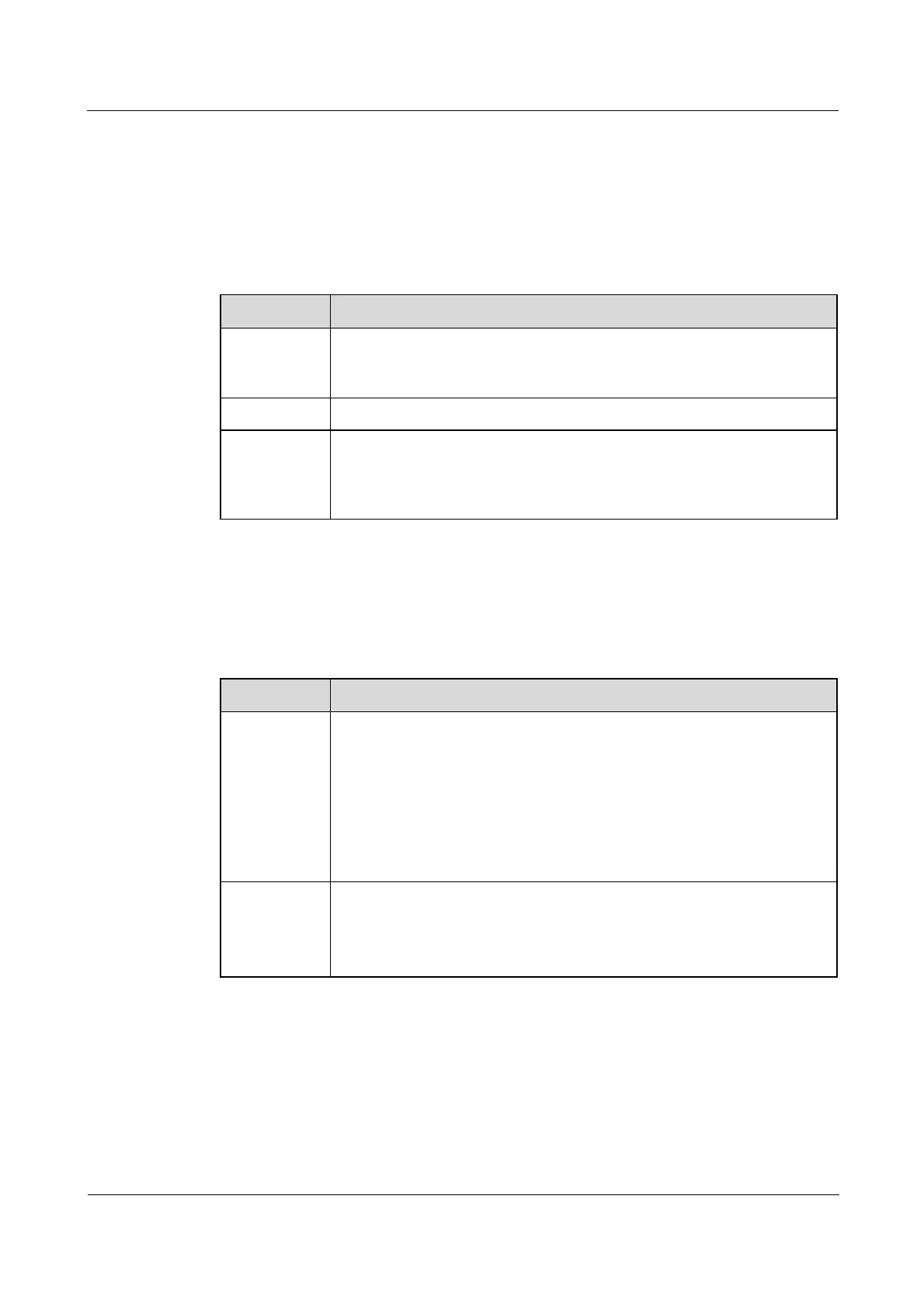

Check the chassis or workbench after installation, as listed in Table 6-6.

Table 6-6 Checking chassis or workbench

Structure attachments are installed correctly and reliably, switches of

doors and locks work normally.

All other connection bolts are installed correctly and reliably, the flat

washers and spring washers are installed in a correct order.

The installation location meets the engineering design manual.

The installation is fixed and reliable and consistent with the anti-seismic

requirements described in engineering design manual.

The connection of earth wire is correct and reliable.

Anti-static wrist is connected to the ESD jack on the rack.

The installation location meets the engineering design manual.

The installation is fixed and reliable and consistent with the anti-seismic

requirements described in engineering design manual.

The connection of earth wire is correct and reliable.

Anti-static wrist is connected to the ESD jack on the rack.

6.5.3 Checking device

After installation is complete, check that the RC1201-2GE16E1T1 is located steadily with

enough space for heat dissipation, operation, and maintenance, and the grounding cable is

correctly connected.

Loading...

Loading...