42

LUBRICATION AND MAINTENANCE

FUEL INJECTOR REMOVAL AND INSTALLATION

The injectors should be cleaned, tested, and

adjusted every 600 hours. Do not disassemble or

adjust the injectors yourself. Remove them from the

tractor engine and have them serviced by your

RANSOMES Tractor Dealer.

To remove the injectors

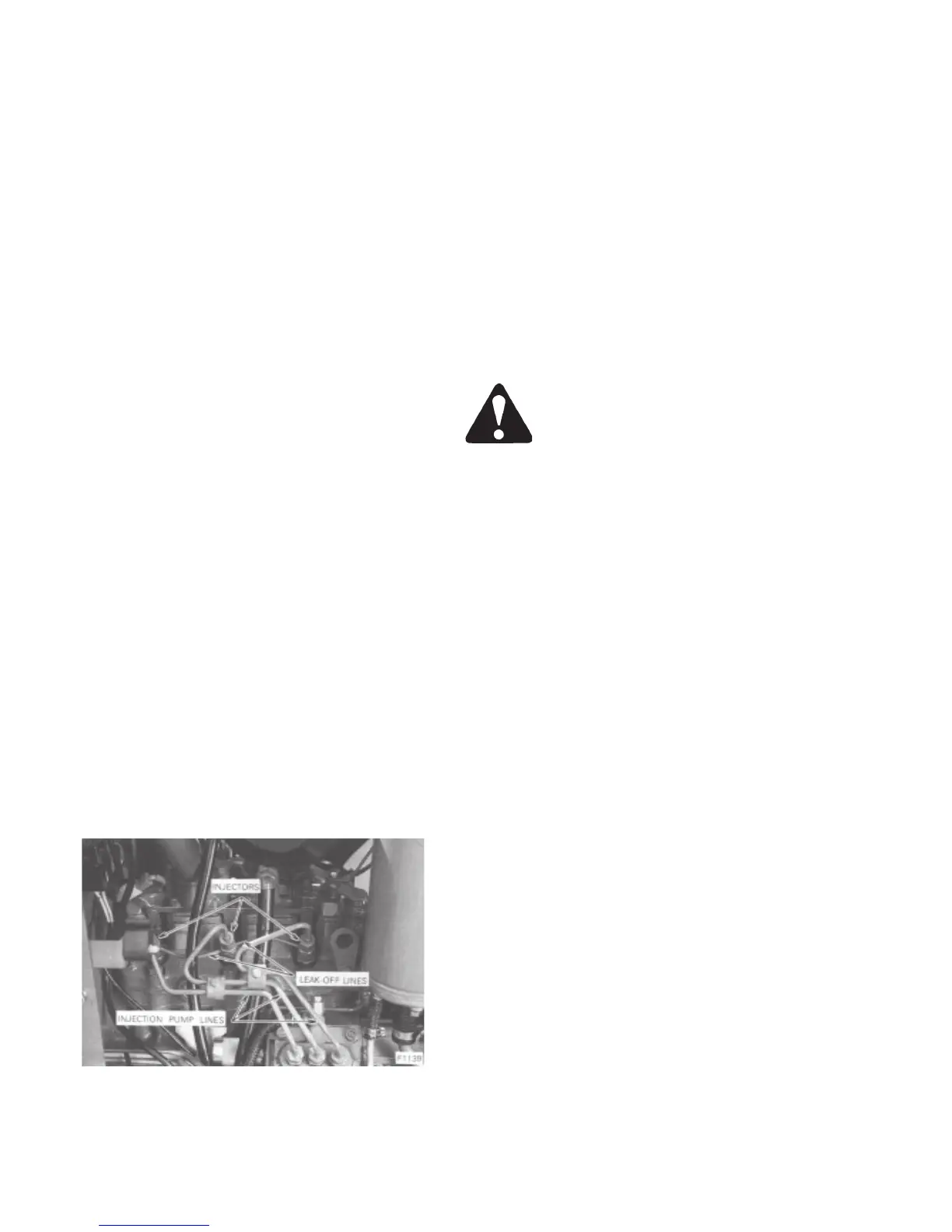

1. Clean all loose dirt from around the injectors

and lines. Disconnect the leak-off lines from

the injectors, Figure 56.

2. Disconnect the injection pump lines at the

pump and injectors. Cover the ends of the

lines and the injector inlet and leak-off ports

to prevent the entry of dirt.

3. Remove the injectors.

4. Remove and discard the copper injector

sealing washers from the injector locating

bores. If a spare set of injectors is not

immediately available, cover the bores to

prevent the entry of dirt.

After the injectors have been serviced, install them

as follows.

1. Install a new copper sealing washer in each

injector locating bore. Install the injectors and

tighten the retaining nut to 22-29 lbs. ft. (29-

39 N.m).

IMPORTANT: Do not overtighten the retaining

nuts. Overtightening may distort the injector.

Figure 56 - Fuel Injector Leak-off Lines

2. Install the injector lines. Finger tighten the

fittings at the injectors until after bleeding the

fuel system. Tighten the fittings at the

injection pump to 58-61 lbs. ft. (78-83 N.m).

3. lnstall the leak-off line. Tighten the leak-off

line nuts to 22-36 lbs. ft. (29-49 N.m).

4. Bleed the fuel system as covered under

“Bleeding the Fuel System,” page 35. Tighten

the injector fittings.

WARNING: Fuel oil in the injection

system is under high pressure and can

penetrate the skin. Unqualified persons

should not remove or attempt to adjust

a pump injector, nozzle or any part of

the fuel injection system.

DO NOT use your hand to check for

leaks. Use a piece of cardboard or

paper to search for leaks.

If any fluid is injected into the skin,

obtain medical attention immediately or

gangrene may result.

Failure to follow these instructions can

result in serious injury.

ENGINE SPEED ADJUSTMENT

The adjustments for idle and maximum no-load

speed settings should be adjusted according to the

following procedures

Idle Speed

1. Pull the throttle lever rearward to the lowest

engine speed, this makes foot throttle free.

2. Adjust to the designated idling engine speed

(800-900 rpm) by adjusting idling stop bolt

and lock it.

Maximum Speed

1. Push the hand throttle lever forward to the

maximum engine speed.

2. To adjust maximum engine speed to 2650-

2700 rpm, elongate outer cable gradually by

tightening the adjusting screw of throttle wire,

and lock the adjusting screw.

Loading...

Loading...