43

LUBRICATION AND MAINTENANCE

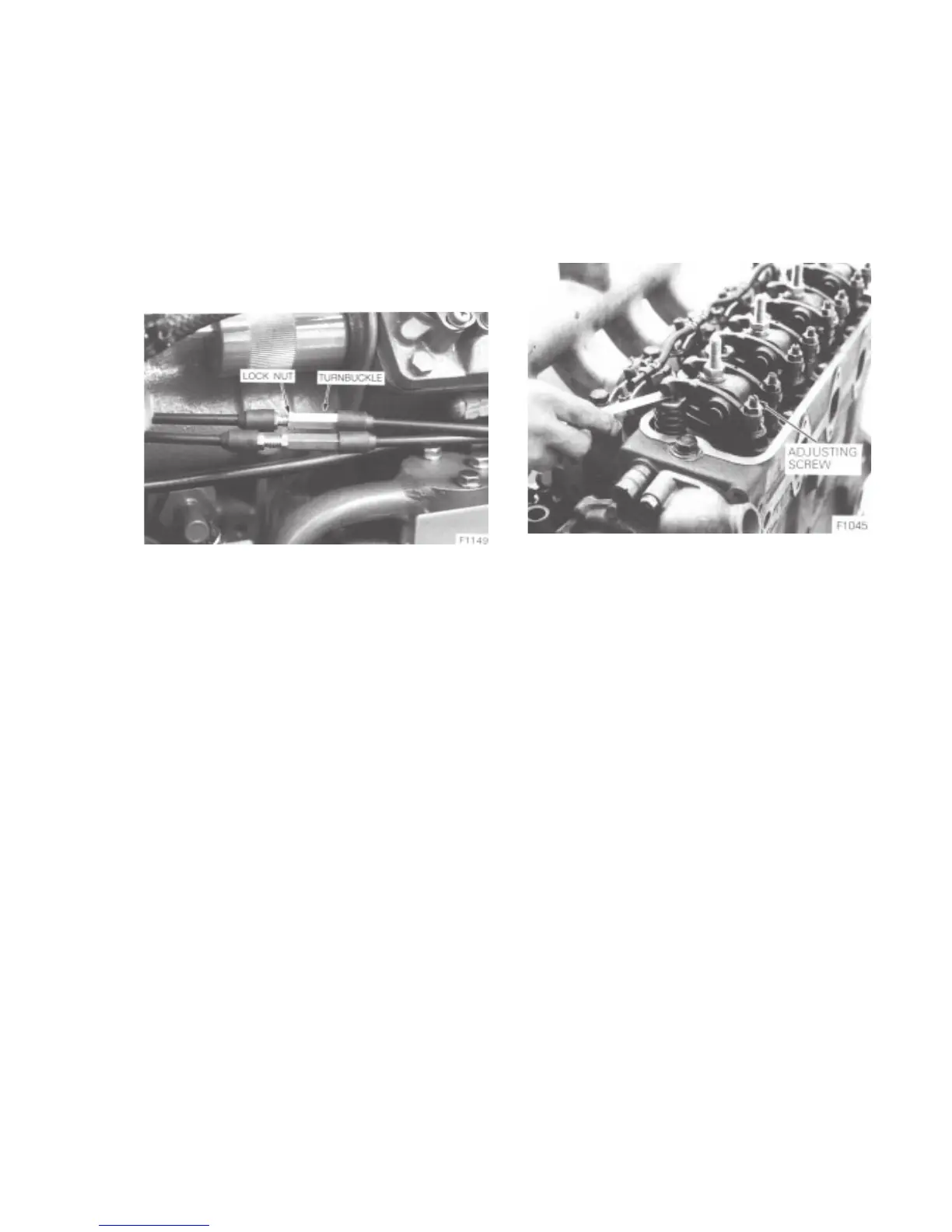

3. To shorten outer cable release the adjusting

screw of throttle wire.

4. Use the same procedure for adjusting

maximum speed on the foot throttle. Lock the

adjusting screw at full throttle pedal stroke.

Figure 57 - Throttle Adjustment

VALVE CLEARANCE (LASH)

Correct valve clearance is one of the most

important factors of good engine performance.

Excessive clearance will cause the engine to

operate excessively noisy, and insufficient clearance

will cause poor performance. Because of this, it is

extremely important that care be used when

adjusting valve clearance.

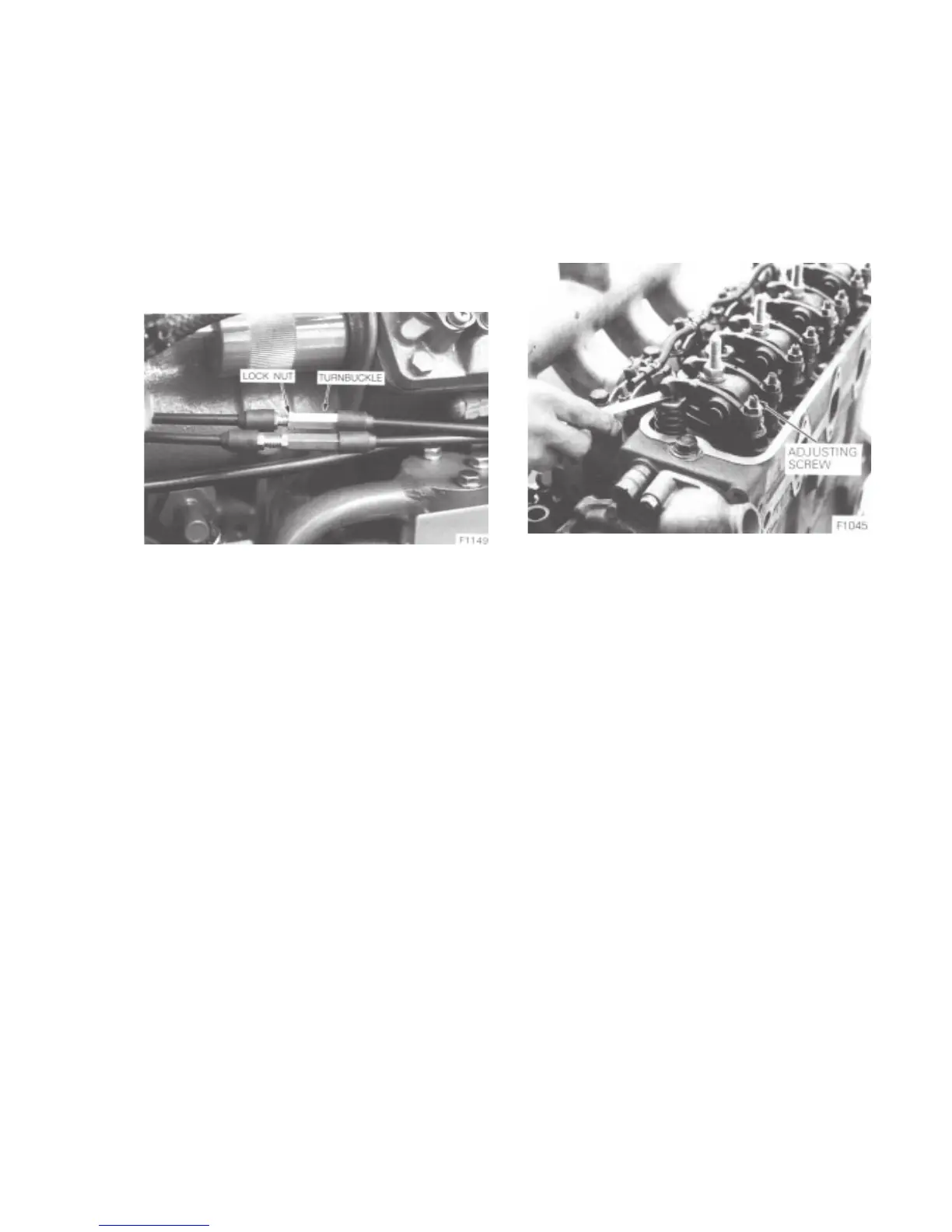

Checking and Adjusting Valve Clearance: Check

and adjust the valves every 600 hours. The

clearance check and adjustment should be made

with the engine cold.

1. Remove the valve rocker arm cover.

2. With the engine idling, check the clearance of

each valve with a feeler gauge, Figure 58.

The setting should be

Intake 008 (.2 mm)

Exhaust 008 (.2 mm)

3. If the clearance is incorrect on any valve, turn

the adjusting screw at the push rod end of the

valve rocker arm either into or out of the arm

while checking for correct clearance with the

feeler gauge.

4. Install the rocker arm cover. Use a new

gasket if the old one is damaged. Tighten the

cover bolts evenly.

Figure 58 - Checking Valve Clearance

MAINTENANCE AND INSPECTION OF

THE ROPS

After the first 20 hours of operation and after every

500 hours of operation or six months, whichever

comes first, do the following

1. Check the torque of the ROPS mounting

bolts. If necessary, tighten the bolts to the

correct torque. See bolt torque’s page 55.

2. Check the operator 5 seat and the mounting

parts for the seat belt. Tighten the bolts to the

correct torque. Replace parts that show wear

or damage.

POSSIBLE DAMAGE TO THE ROPS

If the machine has rolled over or the ROPS has

been in some other type of accident (such as hitting

an overhead object during transport) you must

replace the ROPS to get the original protection.

After an accident, check for damage to (1) the

ROPS, (2) the operator’s seat, (3) the seat belt and

the seat belt mountings. Before you operate the

machine, replace all damaged parts.

IMPORTANT: Do not try to weld or straighten the

ROPS.

Loading...

Loading...