Do you have a question about the Ravaglioli RAV232 NL and is the answer not in the manual?

General safety advice for lift operation, including authorized personnel and prohibitions.

Details on residual risks, protected points, and prevention of accidents.

Description of the padlockable main switch for safety.

Explanation of the deadman system and its function.

Details on mechanical stops and their function during operation.

Explanation of the automatic carriage height synchronization system.

Description of the emergency block and its causes.

Procedures for permitted manoeuvres during emergency.

Function of the nut wear stop and its operation.

Function of the obstacle stop and its operation.

Identification of the danger plate on the machine.

Identification of the warning plate.

Identification of the load capacity plate.

Identification of the serial number plate.

Identification of the voltage plate.

Identification of the waste plate.

Specifications for the lift's load capacity.

Specifications for the three-phase motor.

Specifications for the lift's weight.

Specifications for the lift's noise level.

Instructions for handling and preparing the lift for installation.

Description of the components included in the supply.

Procedure for unpacking, checking for damage, and initial setup.

Instructions for fitting guards, control panels, and supports.

Steps for securing the base, control panel, and motor guard.

Procedure for installing and adjusting the alignment cable.

Steps for lifting and installing the secondary post.

Instructions for fitting the control panel and motor guard.

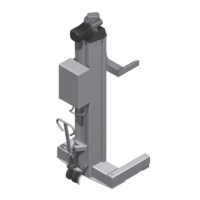

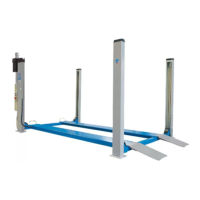

Key technical features of the electromechanical lift.

Information on product testing and compliance with European directives.

Ensuring the installation site meets safety and environmental standards.

Diagrams and specifications for motor connection.

Diagrams and specifications for transformer connection.

Procedure for checking electrical system voltage.

Instructions for connecting the lift to the electrical mains.

Specifications and notes for the power cable.

Diagram showing interconnection of main control panels.

Procedure for converting between 6/8 and 4 pillar configurations.

Instructions for PLC switching between modes.

Diagrams illustrating wiring for various column configurations.

Instructions for connecting cables in different column setups.

Prohibited uses of the lift, including lifting people or dangerous materials.

Guidelines for using approved accessories.

Requirements for trained and authorized personnel.

Safety measures and checks to perform during operation.

Details on main and secondary post controls and their functions.

Instructions for operating the lift in different configurations.

Steps for emergency descent or descent during power failure.

List of common problems, their causes, and remedies.

Explanation of indicator lights and their meanings.

Instructions for lubricating slideways.

Procedure for topping up lubrication tanks.

Instructions for checking main nuts and wear.

Procedure for greasing bearings.

Instructions for checking and adjusting drive belt tension.

Procedure for cleaning and testing safety devices.

Control of retaining screw tightening.

Guidelines for storing the lift for extended periods.

Instructions for making the machine inoperative before scrapping.

Instructions for correct disposal of electrical and electronic equipment waste.

Wiring diagram for the secondary electrical board.

Wiring diagram for the main column electrical system.

Table identifying various labels and danger warning devices.

Importance of regular inspections by specialized personnel.

Checklist for installer to complete during installation.

Checklist for periodic maintenance and control visits.

Details on manufacturer, capacity, serial number, and model.

Instructions on handling and maintaining the machine's identification plate.

| Brand | Ravaglioli |

|---|---|

| Model | RAV232 NL |

| Category | Lifting Systems |

| Language | English |

Loading...

Loading...