Do you have a question about the Raven Case IH AutoBoom XRT and is the answer not in the manual?

Essential safety precautions for operating the Raven system and associated equipment.

Guidelines for safe handling of hydraulic systems and electrical connections for the Raven system.

Recommendations for proper routing of hydraulic hoses to prevent damage and ensure optimal performance.

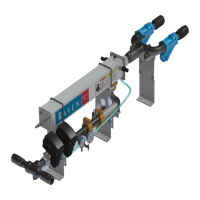

Steps for installing the AutoBoom XRT system and best practices for initial setup and operation.

Information on how to access and receive updates for software and manuals for Raven products.

Overview of the UT interface, home screen access, and basic navigation for the AutoBoom XRT system.

How to use the Master Switch and adjust system sensitivity for optimal boom control.

Setting the target height and selecting measurement targets for the AutoBoom XRT system.

Understanding manual/auto modes and interpreting sensor readings for boom control.

Procedures for performing automatic folding and unfolding of booms for transport and spray positions.

Initial steps for setting up the AutoBoom XRT system, including machine and sensor configuration.

Process for verifying and updating height sensor locations for accurate boom control.

Steps to recalibrate sensors for automatic folding and fore/aft operations.

Calibrating terrain compensation and boom angle sensors for optimal system performance.

Adjusting machine-specific settings, boom width, and control options.

Customizing the display view and configuring preset modes for boom control operations.

Managing height sensor offsets, enabling/disabling, and updating sensor software.

Fine-tuning boom and fold parameters for optimal responsiveness and stability.

Configuring audible alarms and managing feature unlock codes for the AutoBoom XRT system.

Preparing for tuning, ensuring correct dimensions, and performing base control effort calibration.

Testing boom function response to control effort and determining boom speed to effort scale.

Adjusting down speed ratio and proportional, integral, derivative gains for boom control.

Modifying system gain to control overall responsiveness, equivalent to sensitivity settings.

Viewing system status, PWM, blocker status, and control effort for boom sections.

Monitoring fold joint control effort and boom position/velocity readings.

Accessing CAN bus system details and manually controlling boom fold sections.

Checking ABM hardware/software versions and fold/height sensor readings.

Monitoring machine operational data, speed, hours, and voltage levels.

Identifying, viewing, and clearing diagnostic trouble codes for system issues.

Interpreting radar LED status indicators and reviewing system configuration summary.

| Category | Farm Equipment |

|---|---|

| Type | Boom Height Control System |

| Manufacturer | Raven Industries |

| Brand | Case IH |

| Model | AutoBoom XRT |

| Compatibility | Case IH Sprayers |

| Technology | Ultrasonic sensors |

| Function | Maintains optimal boom height for consistent spray coverage |