What to do if low tank volume remaining in Raven Farm Equipment?

- Aamanda91Sep 10, 2025

If the tank volume is low, refill the product to continue field applications.

What to do if low tank volume remaining in Raven Farm Equipment?

If the tank volume is low, refill the product to continue field applications.

What to do if I get a Max PSI/Low PSI Code 104 error on my Raven Water Pump?

To address a Raven Water Pump error related to clogged or restricted pump outlet supply lines, low injection pressure, or incorrect tubing size, first check for any blockages in the outlet supply lines and flush the system to remove clogs. Ensure the correct size of injection outlet tubing is being used. Also, verify that all hand valves are open to allow flow. If the issue persists, consider replacing the pressure transducer.

Why is my Raven Water Pump showing Code 107?

If your Raven Water Pump displays Code 107, it could be due to a clogged pump strainer, restrictions in tubing or plumbing, or the chemical being too thick. Clean the pump strainer and check for obstructions in the injection line. Verify the correct size of injection supply tubing is used. If the chemical is too thick, dilute it in the chemical supply tank, as some chemicals are not suitable for direct injection systems.

What does HC Power Alarm mean on Raven Sidekick Pro?

If you're seeing an 'HC Power Alarm' on your Raven Farm Equipment, the injection node is not connected to high current power. Verify that the high current breaker is not tripped and check the battery connections.

What to do if Raven Sidekick Pro Farm Equipment target flow is too low?

If the target flow is too low: 1. Increase the equipment speed. 2. Increase the target application rate.

What to do if Raven Farm Equipment displays a Low Pressure Alarm?

If you encounter a 'Low Pressure Alarm' on your Raven Farm Equipment, it means the injection pressure is lower than the carrier pressure. To resolve this, perform a pump calibration test; if it fails, clean the injection pump's inlet and discharge valves. Also, calibrate the pump transducer, check the lines between the injection pump and in-line mixer, ensure all hand valves are correctly positioned, and, if necessary, replace the pump transducer.

What to do if Raven Laboratory Equipment shows off rate low?

If the Raven Laboratory Equipment displays an off rate that is too low, check for the following: * Fouled pump check valves * Air leaks on the injection pump inlet * Air in the chemical * Plugged inlet strainer * Chemical too thick to flow through the pump Also, calculate the volume per minute for the application and verify that the rate is within the range of the injection pump.

What to do if Raven Laboratory Equipment displays DI high vacuum error?

If the Raven Laboratory Equipment is showing a DI high vacuum error, follow these steps: 1. Disconnect the vacuum switch from the product cable and test for continuity between pins A and C. If the OHM meter reads a short, the switch is good. If it reads open, the vacuum switch is bad. 2. Check for obstructions from the inlet of the tank. Look for debris in the inlet, a plugged filter/strainer, a hand valve turned in the wrong direction, or an obstruction in the outlet of the chemical tank.

What causes a Low Limit Alarm on Raven Sidekick Pro Farm Equipment?

If you encounter a 'Low Limit Alarm' on your Raven Farm Equipment, the implement speed or width is insufficient to maintain the pump rate, and the pump “low limit” rate has become active. To address this: * Increase vehicle speed. * The pump will maintain the programmed low limit rate. If this rate is the desired lowest injection rate, no action is required. * If the current field operation requires a lower rate of injection, reduce the programmed low limit setting to allow the pump to reduce the rate of injection. Refer to the console or field computer operation manual for additional information on the low limit feature.

What could be the reason for Code 105 on my Raven Water Pump?

If your Raven Water Pump shows Code 105, it might be caused by a flow obstruction in the left exhaust valve or a faulty left pressure transducer. Perform a pump calibration test. If the pump does not calibrate properly, remove the left exhaust cartridge and perform pump maintenance to clear obstructions. If the pump calibrates properly, replace the left pressure transducer.

Guidelines for safe handling and application of agricultural chemicals.

Precautions for safe electrical connections and system operation.

Instructions for safely routing electrical harnesses on the machine.

Instructions for safely routing fluid carrying hoses on the machine.

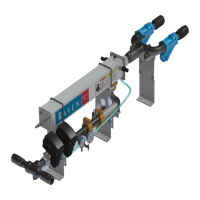

Describes the purpose and function of the Raven Sidekick Pro injection system.

Lists the main components that make up the injection system.

Lists essential components and tools needed for system installation.

Information on software/documentation updates and providing feedback.

Steps to prepare the machine and system before physical installation.

Detailed steps for installing the pump and fill station components.

Instructions for mounting tank support brackets to the machine.

Steps for installing the chemical mixer and its associated plumbing.

Guide for connecting and routing electrical harnesses and components.

Instructions for applying operational decals to system components.

Explains how to operate the valves for chemical tanks.

Describes how to operate the fill station valves.

Details on operating single and dual pump valves.

Instructions for operating recirculation valves for single and dual pumps.

Initial configuration of the Raven OS and system sections.

Details on Product, Injection, Pressure, Section, and Alarm settings tabs.

Procedures for priming and calibrating the Sidekick Pro injection pump.

Process for re-addressing rate controllers on the CAN bus.

Configuring the display to match system settings and equipment.

Configuration of alarm settings for the sprayer or floater control system.

Procedure to calibrate all pressure transducers in the sprayer control system.

Procedure for remote closed-system calibration of the injection pump.

Interpreting LED status indicators on the Sidekick Pro motor control node.

Lists common error codes, their possible causes, and solutions.

List of part numbers for pumps, switches, sensors, and cables.

List of part numbers for mixers, tanks, valves, strainers, and fittings.

Part numbers for support brackets, templates, and operation labels.

Diagram showing electrical connections and component layout.

Diagram illustrating the fluid path and component connections.

| Category | Farm Equipment |

|---|---|

| ISOBUS Compatibility | Yes |

| Display | Touchscreen |

| Connectivity | Wi-Fi, Bluetooth |

| Battery Life | Up to 10 hours |